All we do is usually connected with our tenet ” Client very first, Belief first, devoting about the food stuff packaging and environmental security for 100% Original 2014 Top Stone Coated Roofing Tile Making Machine, We just not only deliver the high quality to our shoppers, but a lot more even important is our greatest provider along with the aggressive selling price.

All we do is usually connected with our tenet ” Client very first, Belief first, devoting about the food stuff packaging and environmental security for Roof Tile Machine, Roof Tile Roll Forming Machine, Stone Coated Roofing Tile Making Machine, Our objective is “to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us”. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Our Steel Colored Stone Coated Production Line meets the diverse requirements of our customers.

The Steel Colored Stone Coated Production Line is described in detail as follows:

NO. 1 Auto bottom glue spraying section

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements) |

| Automatic pressure spray tank | 1set; Capability:200kg; Range:0.6~1Mpa |

| Automatic glue machine motor | Servo motor; Power:750w; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set; Power: 200w |

| Damp proof lamp | 1 pcs; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set; Power: 7.5kw |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Agitator | 1 set; Power: 1.5kw |

NO. 2 Auto stone coated section

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

NO. 3 The first time drying section

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

NO. 4 Auto face glue spraying section

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pcs; Power:100w |

| Automatic pressure spray tank | 1 set; Capability: 200kg; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Automatic glue machine motor | Servo motor; Power: 750w |

NO. 5 The second time drying section

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

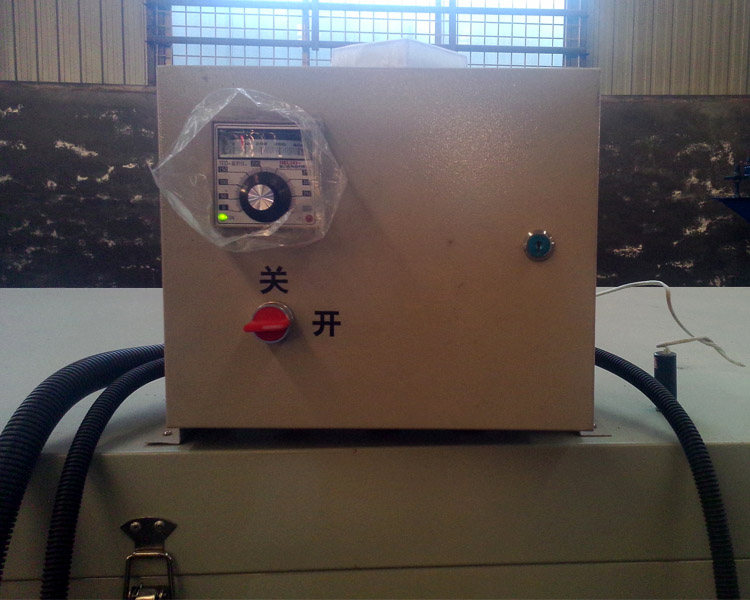

Machine Photos:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Bottom price Machinery Canton Fair 840+850 Doub...

-

2018 Latest Design C Z Purlin Machine For Steel...

-

Wholesale Dealers of Machine Makes Rolling Door...

-

Wholesale Price 45# Carbon Steel Coil Slitting ...

-

Ordinary Discount Factory Metal Roller Shutter ...

-

Big discounting Color Steel Coils Auto Hydrauli...