2017 High quality Ceiling T Grid Forming Machine - Downspout Cold Roll Forming Machine – Haixing Industrial Detail:

The downspout cold roll forming machine is used to manufacture metal pipes that collect roof rainwater and concentrate them on rainwater pipes below the ground.

|

Downspout roll forming machine parameters |

||

| 1 | Material specifications | color-painted galvanized steel sheet |

| 2 | Thickness | 0.40mm to 0.60mm |

| 3 | Main motor power | 7.5kW |

| 4 | Hydraulic station power | 4kW |

| 5 | Feeding width | up to the final design |

| 6 | Cover width | up to the final design |

| 7 | Coil yield strength | Q235MPa (33KSI) |

| 8 | Roll forming speed | 10-12m/min |

| 9 | Cutting tolerance | ±2mm |

| 10 | Rollers material | no 45 steel coated with chrome |

| 11 | Cutting blades material | Cr12 mold steel |

| 12 | Manual decoiler Max capacity | 3000kg |

| 13 | Type of cutting | roll-formed and length-set cutting |

| 14 | Control system | Mitsubishi PLC, inverter and touchscreen |

| 15 | Encoder | Omron |

Main components of Downspout cold roll forming machine:

Decoiler: 1 set

Sheet gilding device: 1 set

Roll former: 1 set

Hydraulic cutting device: 1 set

PLC control system: 1 set

Supports tables: 1 set

Downspout curving machine: 1 set

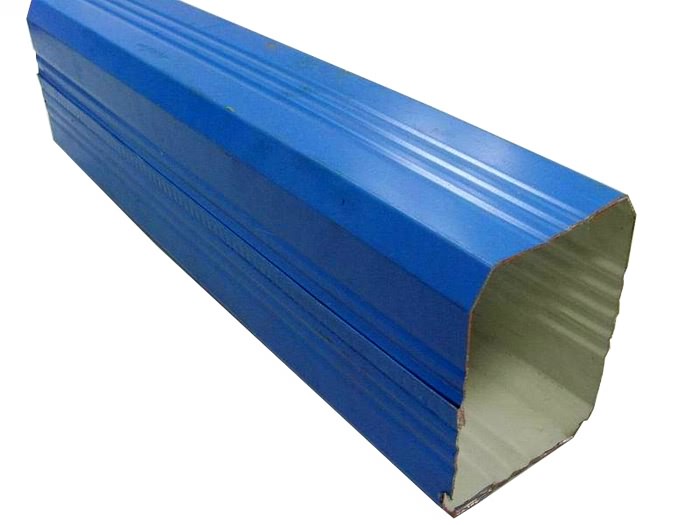

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

The Top Yachts at the Fort Lauderdale International Boat Show | Floor Deck Macking Machine

Meet siblings who fell 25 feet in deck collapse, lived to warn other homeowners | Floor Deck Macking Machine

2017 High quality Ceiling T Grid Forming Machine - Downspout Cold Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Manufactur standard Bender Bending Machine - S...

-

OEM/ODM China T Grid Ceiling Keel Making Machin...

-

High Quality for Colored Shutter Door Frame Lig...

-

China New Product Double Layer Roofing Sheet Ro...

-

factory low price Steel Profile Roller Shutter ...

-

Original Factory Nail Making Machine Complete L...