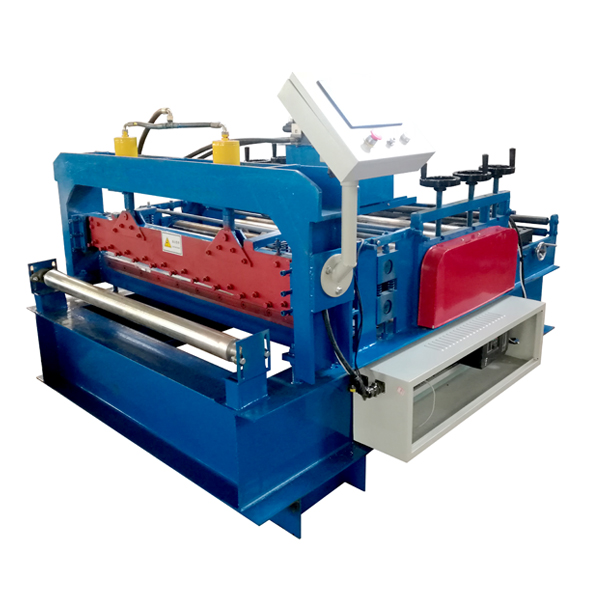

2017 New Style Roof Cold Forming Machine - Double Layer Roof Panel Roll Forming Machine – Haixing Industrial Detail:

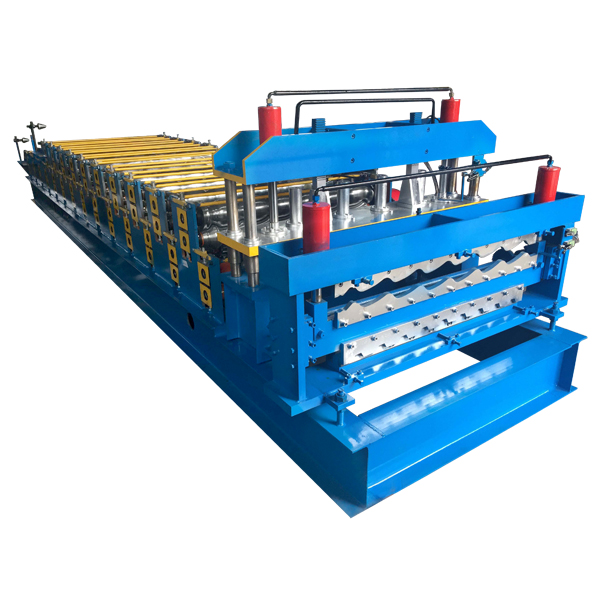

Double layer roof panel roll forming machines can press two types of tiles of different versions.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

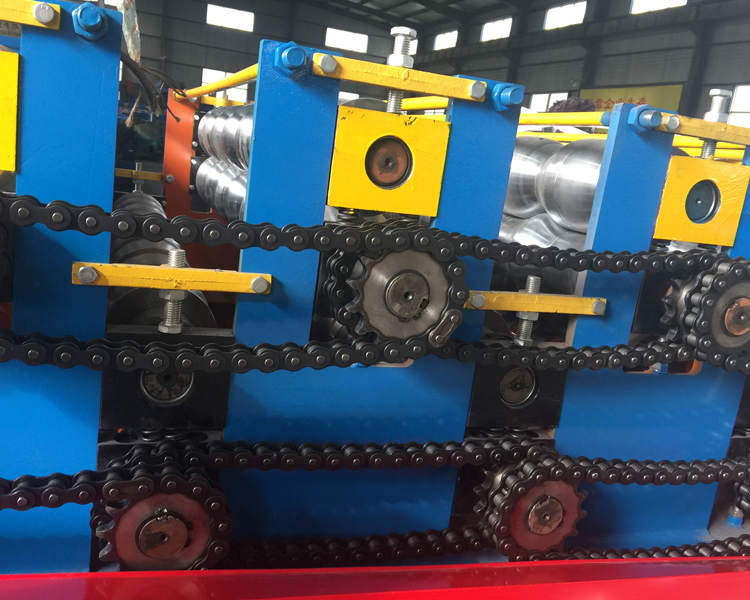

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 2set

Electric-motor: 1 set

Cutting device: 2 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

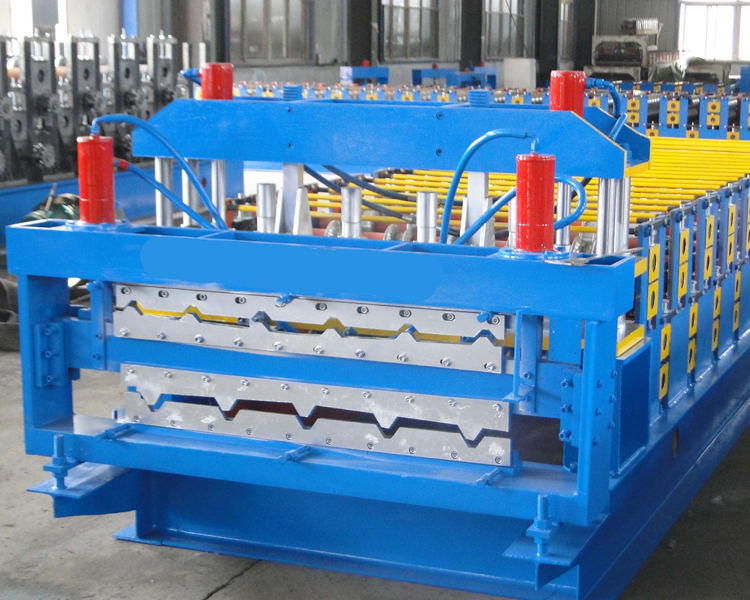

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

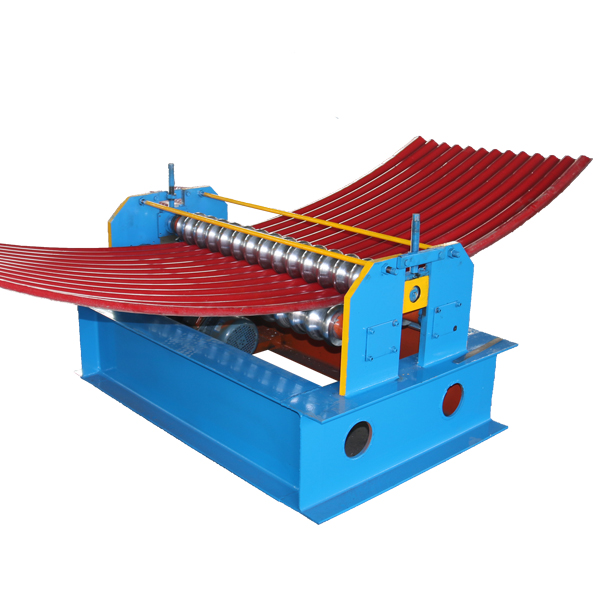

Product detail pictures:

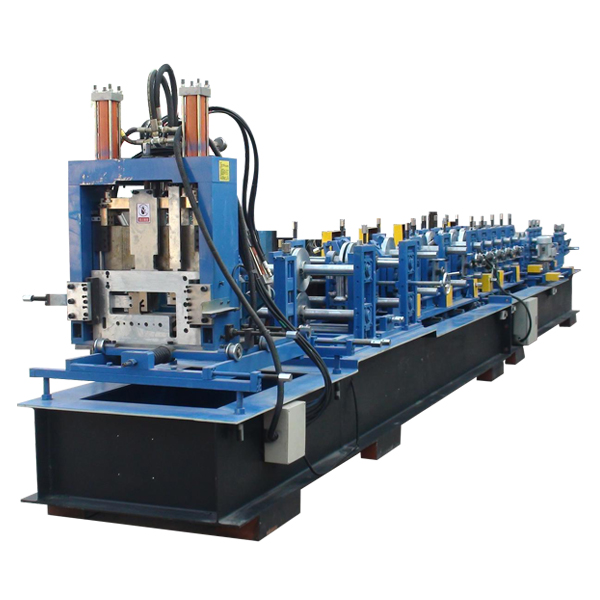

Related Product Guide:

Viking Orion: Peek inside Viking Cruises’ latest ship in photo tour | Roof Sheet Curving Machine

How the African elephant cracked its skin to cool off | Roof Sheet Curving Machine

2017 New Style Roof Cold Forming Machine - Double Layer Roof Panel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

OEM/ODM Supplier Pipe Forming Equipment - Auto...

-

Best-Selling Auto Nail Making Machine - Person...

-

Special Price for Slitting Machine Metal Coil -...

-

China wholesale Auto-Punch C Purlin Machine - ...

-

Excellent quality Water Gutter Making Machine -...

-

Massive Selection for Roof Sheet Rolling Machin...