It adheres on the tenet “Honest, industrious, enterprising, innovative” to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for 2019 Good Quality Efficiency Metal Sheet Roof Tile Production Line, Our Lab now is “National Lab of diesel engine turbo technology ” , and we own a qualified R&D staff and complete testing facility.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to develop new items frequently. It regards buyers, success as its very own success. Let us produce prosperous future hand in hand for Color Roof Tile Machine, Roof Tile Production Line, Steel Frame Machine, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

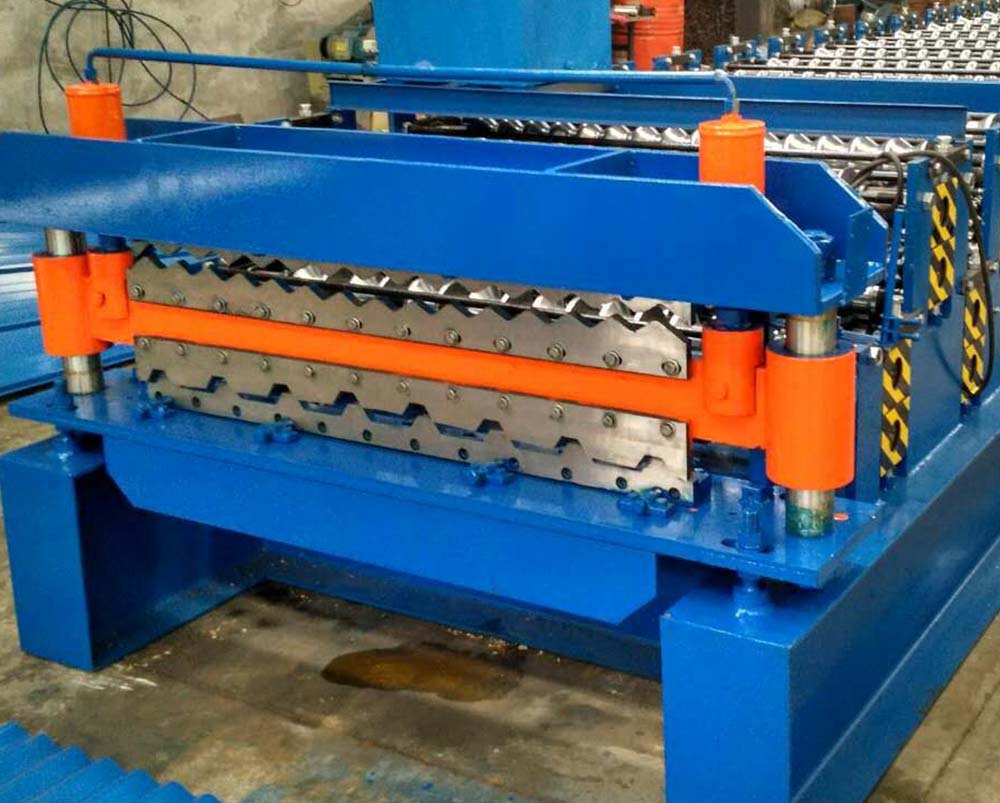

Parameters of double layer metal corrugated tile making machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Components of double layer corrugated roof sheet making machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our company owned professional design team, we can design different profile according customer’s demands.

-

Low price for C U T L Omega Channel Roll Formin...

-

China OEM Roller Shutter Door Frame Cold Roll F...

-

Well-designed Xh 850 /840 Double Layer Color St...

-

Wholesale OEM/ODM China Hydraulic Decoiler with...

-

Factory Directly supply Byt-228 Stainless Steel...

-

Factory Promotional Speed Flat Decoiler Machine