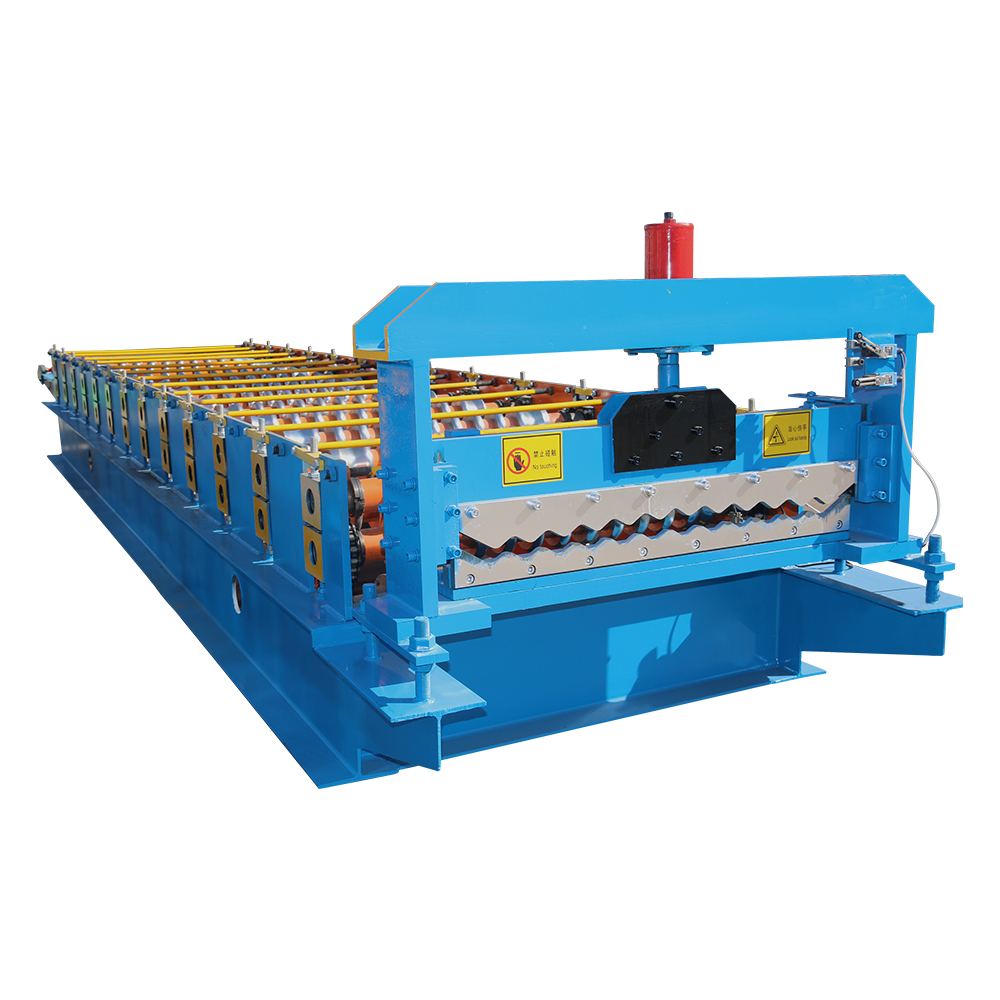

Best quality Sandwich Panel Roll Forming Machine - EPS Sandwich Wall Panel Forming Machine – Haixing Industrial Detail:

EPS sandwich wall panel forming machine includes a decoiler, main body and rear cutting equipment. The lamination system includes feed, glue, heat, lamination and post cutting.

|

EPS Sandwich Wall Panel Forming Machine parameters |

||

|

1 |

Equipment overall dimensions |

30m*2.6m*3m |

|

2 |

Total weight |

About 16 ton |

|

3 |

Control system |

Omron encoder PLC |

|

4 |

Main motor power |

Planetary cycloid reducer, 4kw, 380V, 50HZ |

|

5 |

Processing speed |

4~4.5 m/min, continuous stepless adjusted, variable frequency speed regulation, digital display |

|

6 |

raw material |

1.2 meters |

|

7 |

Voltage |

380V |

|

8 |

Roller material |

chrome plated on 45# steel forgings |

|

9 |

Number of rubber shafts |

27 foams, 39 rock wool |

|

10 |

Total power |

30 kw |

|

11 |

Synchronous controller |

Digital synchronous controller |

|

12 |

Corrugated press motor power |

Double-stage cycloid reducer 4kw, 380V, 50HZ |

|

13 |

Application |

roof panel, wall panel |

EPS Sandwich Wall Panel Forming Machine working flow:

1) Decoiling: feeding of the material for bottom metal strip.

2) Roll forming: producing the bottom metal strip for roof or wall panel.

3) EPS feeding table: placing the middle part of the sandwich panel.

4) Dripping glue onto the top and bottom metal strip.

5) Heading the strips for better adhesion of glue.

6) Rolling edges of the strips.

7) Connecting parts and roll forming together.

8) Make slot (milling cutting to cut the extra parts of EPS) of panels for specific length.

9) Confirming length.

10) Cutting adjusted by PLC.

11) Stacker table.

Machine picture display

Packaging and Shipping

1) Tighten the container with a wire rope and weld the container to the container with natural iron.

2) Main forming machine and un-coiler is naked (we can also use waterproof plastic packaging if needed).

3) PLC control system and motor pump are packed in wooden box with water proof paper coverage.

Product detail pictures:

Related Product Guide:

Springfield company begins making tape for cassettes | Steel Downpipe Roll Forming Machine

2019 Jaguar i-Pace Year 2 Review: Continuing the British BEV Response to Tesla Amongst a Beginning German BEV Onslaught | Decoiler In Color Coating Line

Best quality Sandwich Panel Roll Forming Machine - EPS Sandwich Wall Panel Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

2017 Latest Design Curved Cladding Sheets Machi...

-

Hot sale Factory Rockwool Sandwich Panel Machin...

-

China New Product Press Machine For T Grid - A...

-

Factory Outlets Corrugated Sheet Manufacturing ...

-

China Gold Supplier for Roof Tile Machine Maker...

-

High Performance Used Steel Plate Straightening...