China Gold Supplier for Round Downspouts Machines - Floor Deck Cold Roll Forming Machine – Haixing Industrial Detail:

Floor deck cold roll forming machine parameters

|

Feeding platform |

1 | Frame structure: steel plate welded |

| 2 | roller flatting system and pre-hand cutting system | |

| 3 | Advantage: not scratch the surface of metal plate | |

|

Roll forming M/C |

1 | Machine weight: 13 tons |

| 2 | Installation dimensions: 1500*1800*1500mm | |

| 3 | Machine under frame: steel 400 H-beam | |

| 4 | Sidewall: 45# steel plates | |

| 5 | Roller stations: 28 rows | |

| 6 | Shaft diameter: 85mm | |

| 7 | Side wall plate: 24mm | |

| 8 | Main shaft material: 45# steel with finish turning | |

| 9 | Roller material: 45# forging steel with chromium plate | |

| 10 | Chromium plate thickness: 0.05mm | |

| 11 | Motor power: 15kW*2, brand Siemens | |

| 12 | Reducer type: 2-8# gear speed reducer-Shanghai, China | |

| 13 | Chain wheel and cycle chain: 1.2-inch | |

| 14 | Production line speed: 10-12m/minutes | |

|

PLC control system |

1 |

Functions: adapts quantity cutting system, length of roof sheet can be set on the computer |

| 2 | Tolerance: within 1.0mm | |

| 3 |

Frequency converter: Delta |

|

| 4 |

PLC is Siemens |

|

| 5 |

Encoder: Omron |

|

| 6 |

Touchscreen: Delta |

|

| 7 |

Voltage standard: 3 phases 380V/50Hz or according to customer’s need |

|

| 8 |

Pressing die material: Cr12 |

|

|

Hydraulic pressing device |

1 |

Quenched treatment 58 to 62ºC |

| 2 |

Length tolerance: ±2mm |

|

| 3 |

Pump station motor: 5.5kW, LICHAO, Shanghai |

|

| 4 |

Hydraulic oil: 40# |

|

|

Hydraulic cutting device |

1 |

Functions: adapts electric drive and automatic location system to decide the dimension and cut the target |

| 2 |

Working method: stop to post then post to cut |

|

| 3 |

Cutting mold material: Cr12 |

|

| 4 |

Quenched treatment 58 to 62°C |

|

| 5 |

Length tolerance: ±2mm |

|

| 6 |

Pump station motor: 5.5kW, LICHAO, Shanghai |

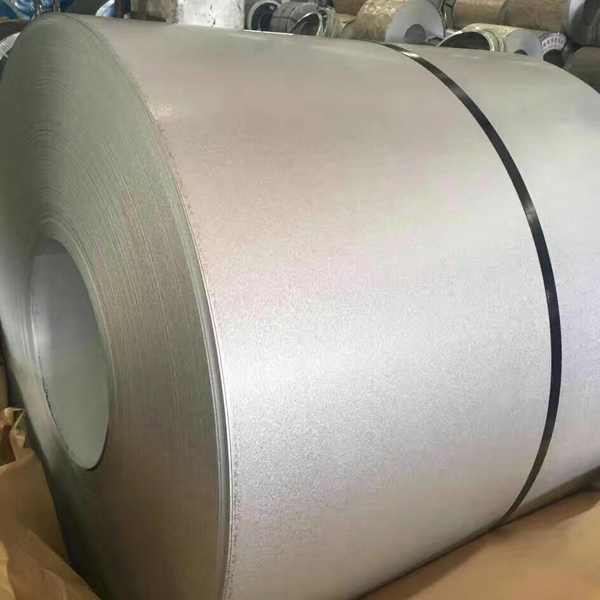

Photos of floor deck cold roll forming machine

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

About the floor deck cold roll forming machine and other roll forming machine details, if you have any need and questions, please don’t hesitate to contact us.

Product detail pictures:

Related Product Guide:

Springfield company begins making tape for cassettes | Ibr Roof Sheet Making Machine

Transforming buildings into icons - Nikkei Asian Review Arrow Artboard Artboard Title Chevron Cross Eye Icon Icon Facebook Icon Linkedin Shape Icon Mail Contact Path Layer Icon Mail Menu Burger Positive Arrow Icon Print Icon Search Si | Ibr Roof Sheet Making Machine

China Gold Supplier for Round Downspouts Machines - Floor Deck Cold Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

OEM/ODM Manufacturer Tee Wall Angle Ceiling Mak...

-

2017 Good Quality Hydraulic Cold Sheet Floor De...

-

China Factory for Metal Ceilling T Bar Roll For...

-

Factory Free sample Simple Vertical Slitting Ma...

-

Chinese wholesale Metal Deck Cold Roll Forming ...

-

Special Price for Used Manual Metal Bending Mac...