China Supplier Metal Roof Truss Roll Forming Machine - Quots for Nc Bending Machine/nc Bender(wc67y-80t/2500) – Haixing Industrial Detail:

Our enterprise sticks to the basic principle of “Quality may be the life of the firm, and status could be the soul of it” for Quots for Nc Bending Machine/nc Bender(wc67y-80t/2500), Competitive price with high quality and satisfying service make us earned more customers.we wish to work with you and seek common development.

Our enterprise sticks to the basic principle of “Quality may be the life of the firm, and status could be the soul of it” for Hydraulic Bending Machine, Nc Bending Machine, Press Brake, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

|

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

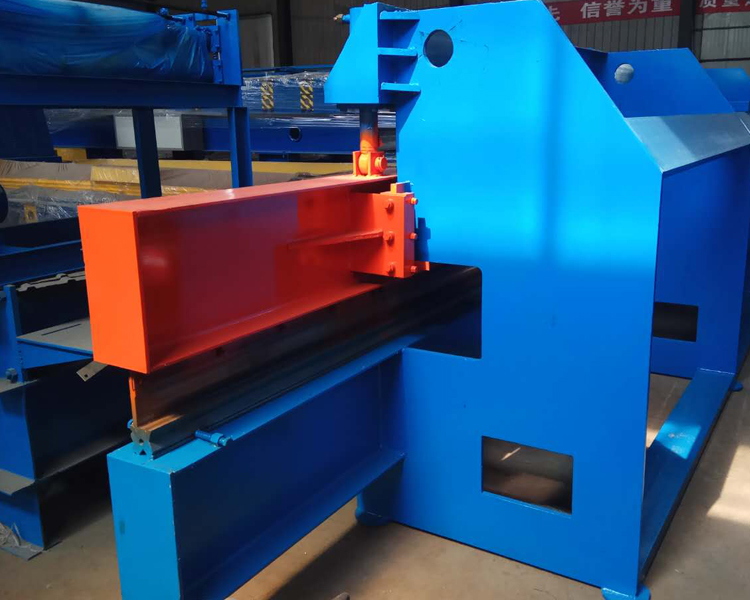

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Specifications for Commercial Skylights | Floor Deck Macking Machine

The sci-fi future stands derelict: Taiwan’s abandoned UFO houses | Floor Deck Macking Machine

China Supplier Metal Roof Truss Roll Forming Machine - Quots for Nc Bending Machine/nc Bender(wc67y-80t/2500) – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Special Design for Double Layer Machine - 10 t...

-

Leading Manufacturer for Steel Keel Profile Mac...

-

Good Quality Roofing Sheet Stone Coated Machine...

-

OEM/ODM Factory Color Stone Roof Production Lin...

-

Factory Outlets Corrugated Sheet Manufacturing ...

-

Factory source Tile Moulding Machine - Hydraul...