We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Chinese Professional 2016 New Roof Use Double Layer Corrugated Profile Steel Roofing Sheet Roll Forming Machine Roof Tile Making Machine, Inspired by the rapid developing market of the fast food and beverage consumables all over the world , We are looking forward to working with partners/clients to make success together.

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for Metal Roofing Coil, Metal Roofing Roll Forming Machine, Rolling Machine, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

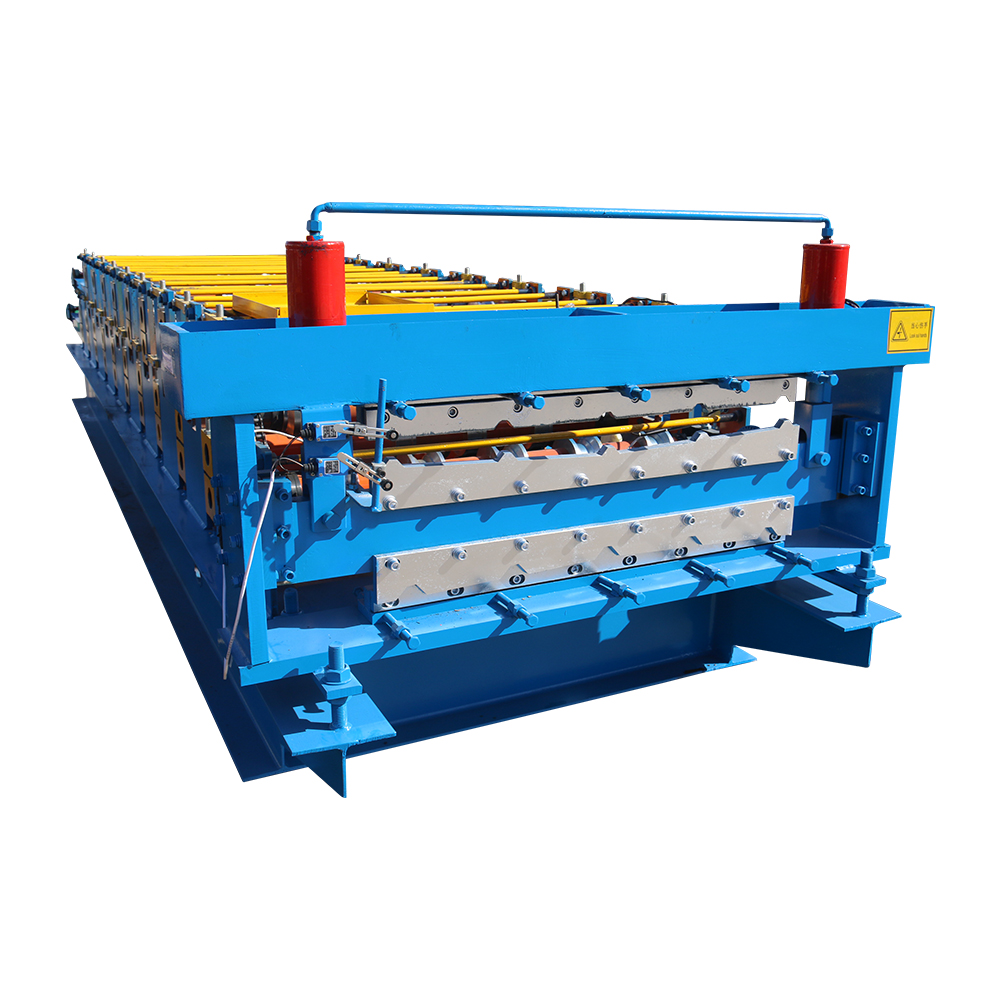

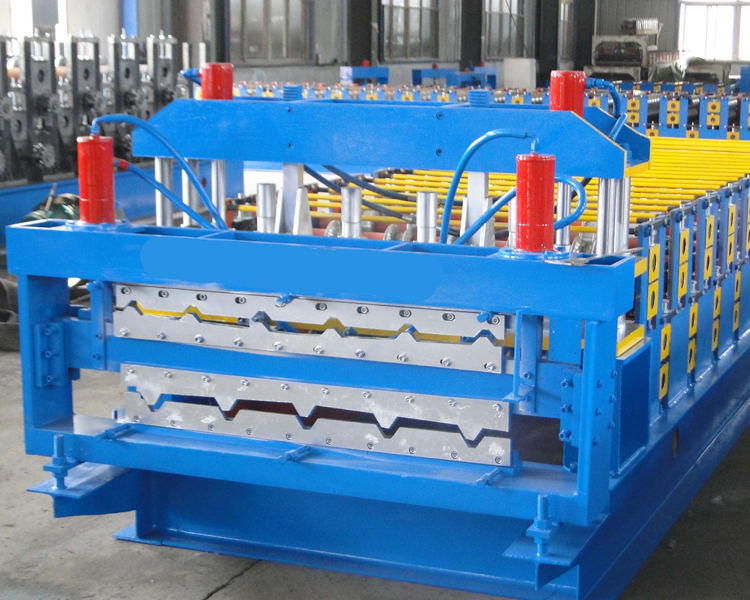

Double layer roofing roll forming machines can press two types of tiles of different versions. It can produce various of steel roof and wall panel, it is a new building materials, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theater, etc.

|

Double Layer Roofing Roll Forming Machine |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 2set

Electric-motor: 1 set

Cutting device: 2 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

FAQ

Q:Are you a manufacturer?

A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What’s the delivery time?

A: Normally will take 60 days, for small lines will take 30 days.

Q:Do you have after-sale support?

A:Yes, we’re always here for giving you advice and support for technical details since we have senior technician.