Factory best selling Roof Sheet Curving Roll Forming Machine - Reasonable price for New Coming Roof Tile Metal Roll Forming Machine/stone Coated Roof Tile Production Line – Haixing Industrial Detail:

We attempt for excellence, provider the customers”, hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Reasonable price for New Coming Roof Tile Metal Roll Forming Machine/stone Coated Roof Tile Production Line, Your assistance is our eternal electrical power! Warmly welcome buyers at your home and abroad to go to our organization.

We attempt for excellence, provider the customers”, hopes to be the most beneficial cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes value share and continuous advertising for Stone Coated Roof Tile Production Line, Since its foundation , the company keeps living up to the belief of “honest selling , best quality , people-orientation and benefits to customers. ” We’re doing everything to supply our customers with best services and best products and solutions . We promise that we are going to be responsible all the way to the end once our services begin.

Our Steel Colored Stone Coated Production Line meets the diverse requirements of our customers.

The Steel Colored Stone Coated Production Line is described in detail as follows:

NO. 1 Auto bottom glue spraying section

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements) |

| Automatic pressure spray tank | 1set; Capability:200kg; Range:0.6~1Mpa |

| Automatic glue machine motor | Servo motor; Power:750w; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set; Power: 200w |

| Damp proof lamp | 1 pcs; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set; Power: 7.5kw |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Agitator | 1 set; Power: 1.5kw |

NO. 2 Auto stone coated section

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

NO. 3 The first time drying section

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

NO. 4 Auto face glue spraying section

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pcs; Power:100w |

| Automatic pressure spray tank | 1 set; Capability: 200kg; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Automatic glue machine motor | Servo motor; Power: 750w |

NO. 5 The second time drying section

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

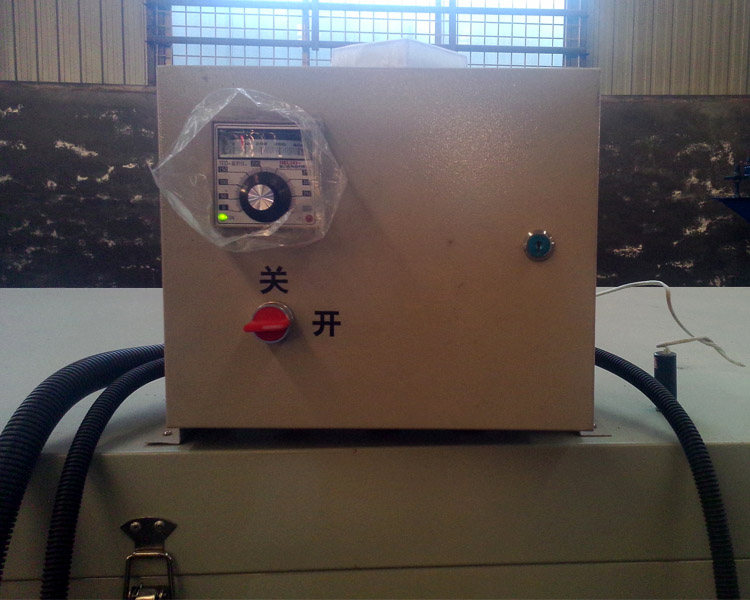

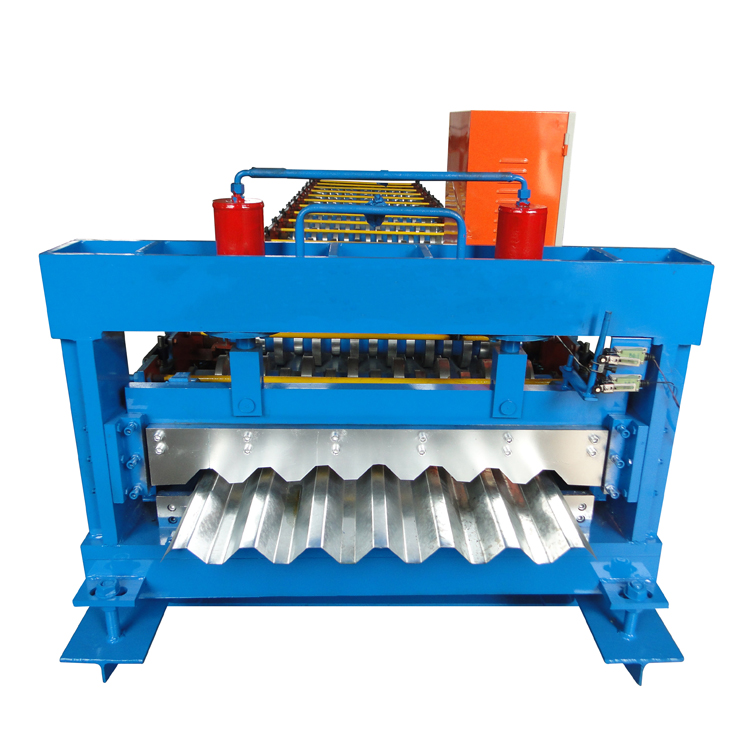

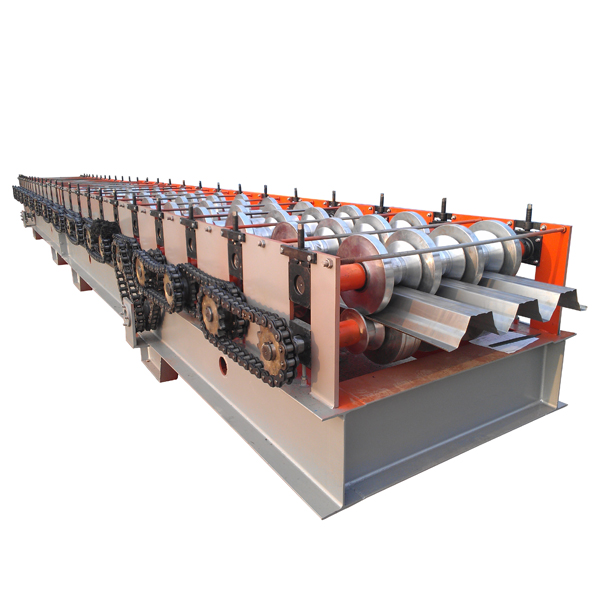

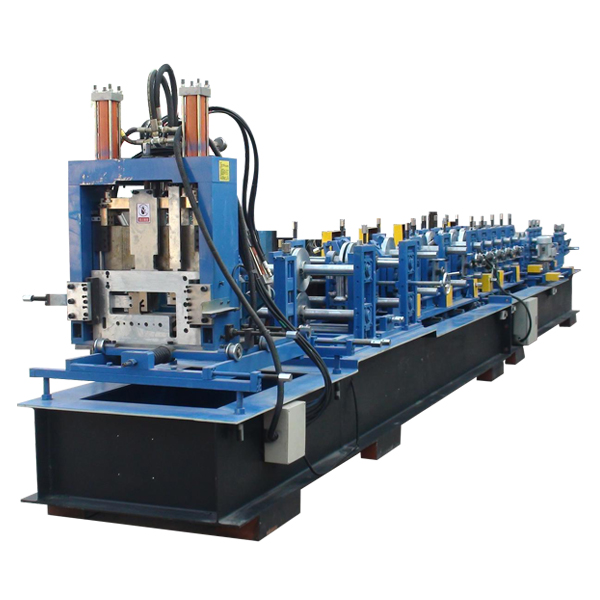

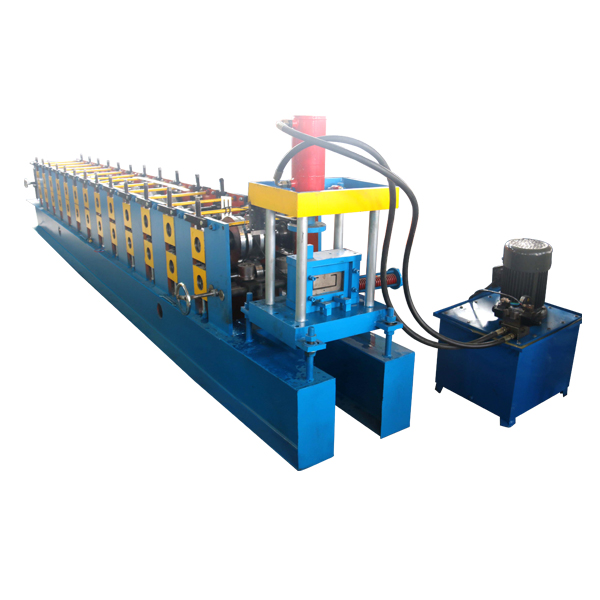

Machine Photos:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Product detail pictures:

Related Product Guide:

Five Classic Designs That Help Kids Become Independent | Decoiler In Color Coating Line

Studio Morison’s shelter is designed for when nature reclaims the planet | Steel Downpipe Roll Forming Machine

Factory best selling Roof Sheet Curving Roll Forming Machine - Reasonable price for New Coming Roof Tile Metal Roll Forming Machine/stone Coated Roof Tile Production Line – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Lowest Price for Tile Floor Machine - Galvaniz...

-

Reliable Supplier Machine For Decoiling Straigh...

-

Factory For Gutter Cold Rolling Forming Machine...

-

China Gold Supplier for Round Downspouts Machin...

-

Newly Arrival Mini Bending Machine - C Shape P...

-

Special Price for Decking Floor Plate Making Ma...