The corporation keeps to the operation concept “scientific management, superior quality and performance primacy, consumer supreme for Factory For Hot Sale Sheet Metal Roll Forming, We have been self-assured to make excellent achievements within the future. We’ve been looking forward to becoming one within your most trusted suppliers.

The corporation keeps to the operation concept “scientific management, superior quality and performance primacy, consumer supreme for Cold Roll Forming Machine, Hot Sale Sheet Metal Roll Forming, Metal Roofing Roll Forming Machine, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. “Your satisfaction is our happiness”.

The tiles pressed out by the glazed roofing tile roll forming machine are very beautiful, and the technical parameters of the machine are as follows:

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

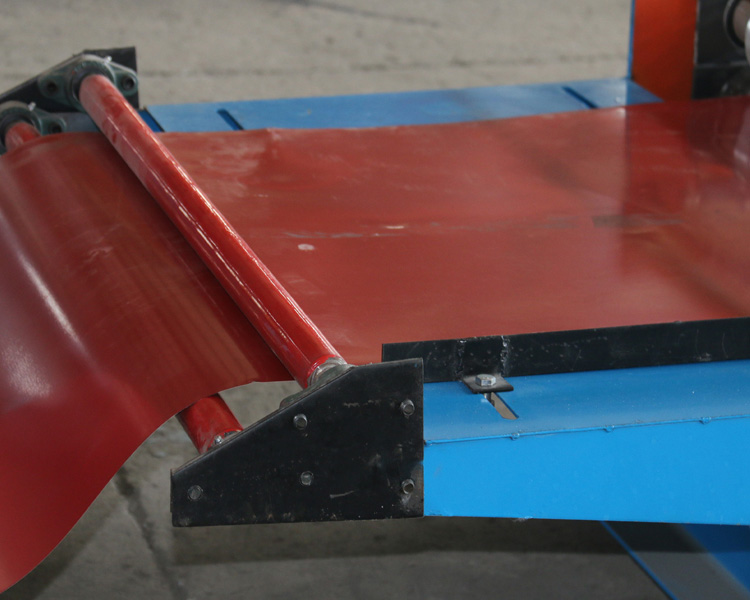

Glazed roofing tile roll forming machine components include: Manual un-coiler, Guiding platform, Coil strip leveler, Main machine of roll forming, Electric-motor, Cutting device, Hydraulic station, PLC control and Supporter table.

Machine Details:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.