Factory making Ceiling Light Steel Keel Roll Forming Machine - Corrugated Roof Panel Roll Forming Machine – Haixing Industrial Detail:

Corrugated roof sheets made of corrugated roof panel roll forming machines are often used for architectural decoration.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16 mm |

| 8 | Chain size | 1 Inch |

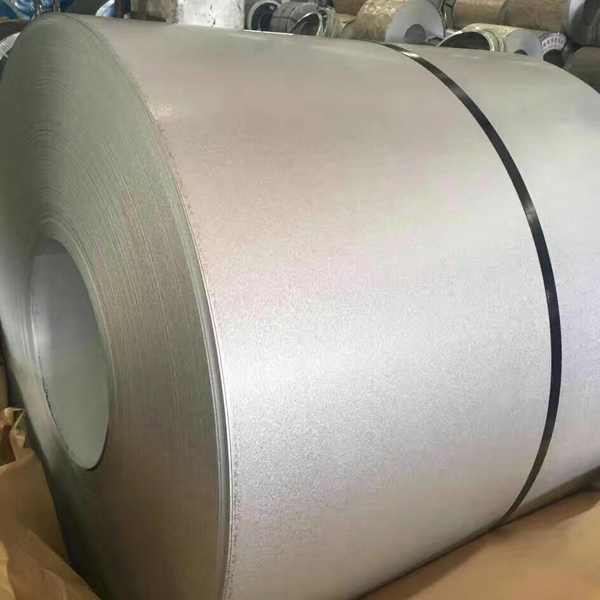

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

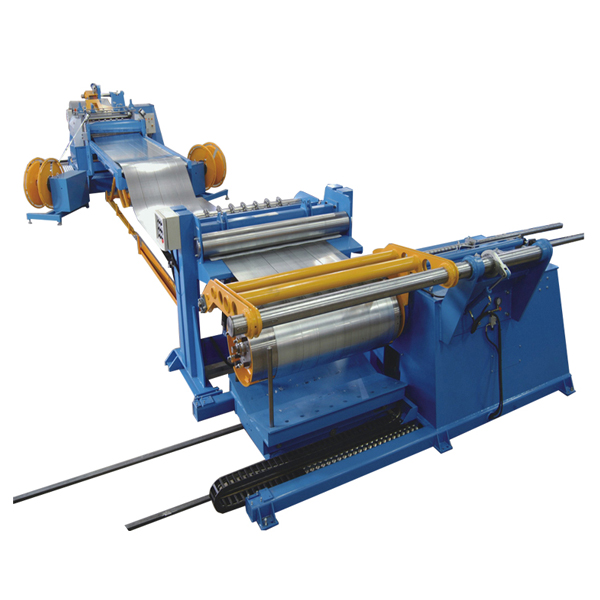

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

LEGO Creator Expert 10264 Corner Garage [Review] | The Brothers Brick | Decoiler In Color Coating Line

Transforming buildings into icons - Nikkei Asian Review Arrow Artboard Artboard Title Chevron Cross Eye Icon Icon Facebook Icon Linkedin Shape Icon Mail Contact Path Layer Icon Mail Menu Burger Positive Arrow Icon Print Icon Search Si | Ibr Roof Sheet Making Machine

Factory making Ceiling Light Steel Keel Roll Forming Machine - Corrugated Roof Panel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

China Supplier Roof Panel Making Machine - Ste...

-

Special Price for Changeable C/Z Shape Purlin R...

-

Wholesale Discount Nail Making Machine Automati...

-

Renewable Design for Curving Machine - Trendin...

-

Original Factory Ceiling Cross T Grid Roll Form...

-

OEM/ODM Factory Aluminium Gutter Machine - Alu...