High definition Cross T Section Steel Grid Manufacturer - Rain Gutter Cold Roll Forming Machine – Haixing Industrial Detail:

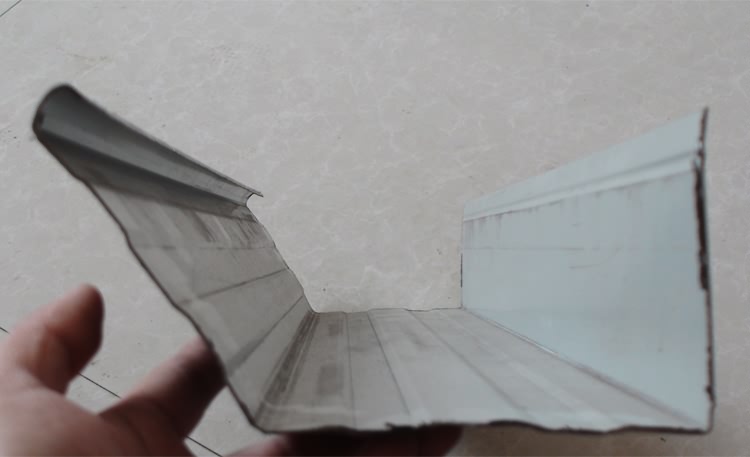

Rain gutter cold roll forming machine can bend the roll formed pipe, and let the drainpipe and the bending connect to be the whole. The product after roll forming has long working time than the traditional PPC pipe, and not aging.

|

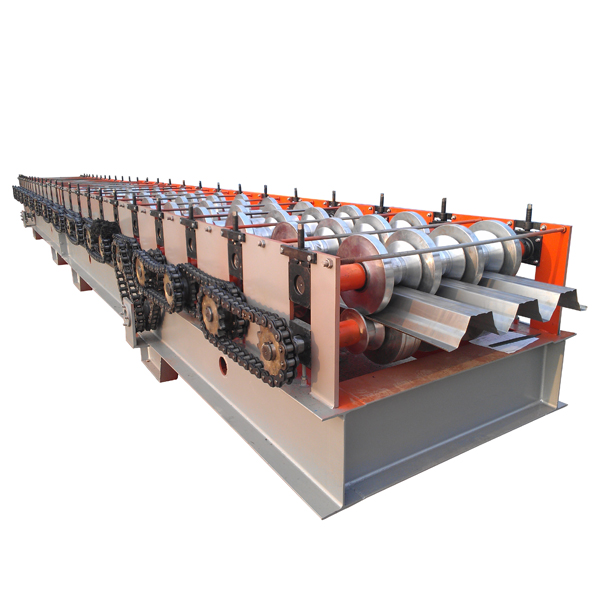

Rain gutter roll forming machine parameters |

||

| 1 | Suitable to process | Color steel plate, galvanized sheet, aluminum coils and more. |

| 2 | Width of the feeding material | According to the profile |

| 3 | Rollers station | 18 rows |

| 4 | Thickness of feeding material | 0.3-0.8mm |

| 5 | Power | 4+4kw |

| 6 | Size | 8500*800*1500mm |

| 7 | Productivity | 8-12m/min |

| 8 | Diameter of shaft | 52mm |

| 9 | Weight | About 4.8 T |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Rolling material | Carbon Steel 45# |

| 12 | Material of the cutting plate | Cr12 |

| 13 | Wall thickness of main forming machine | 16mm steel plate |

| 14 | Main structure of the machine | 300 H steel |

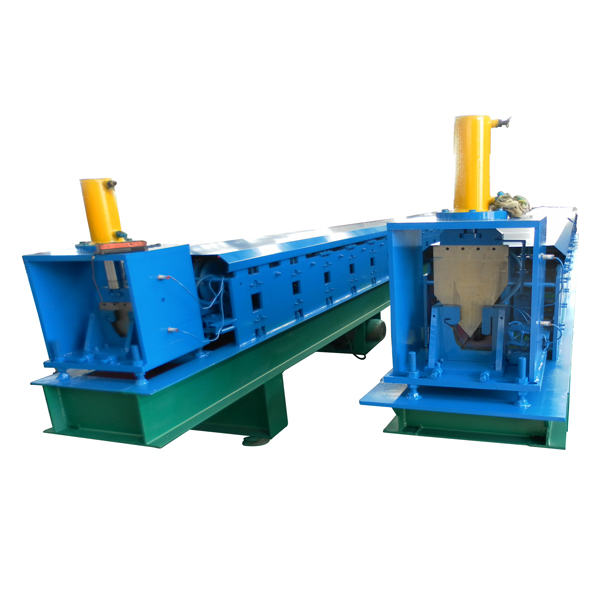

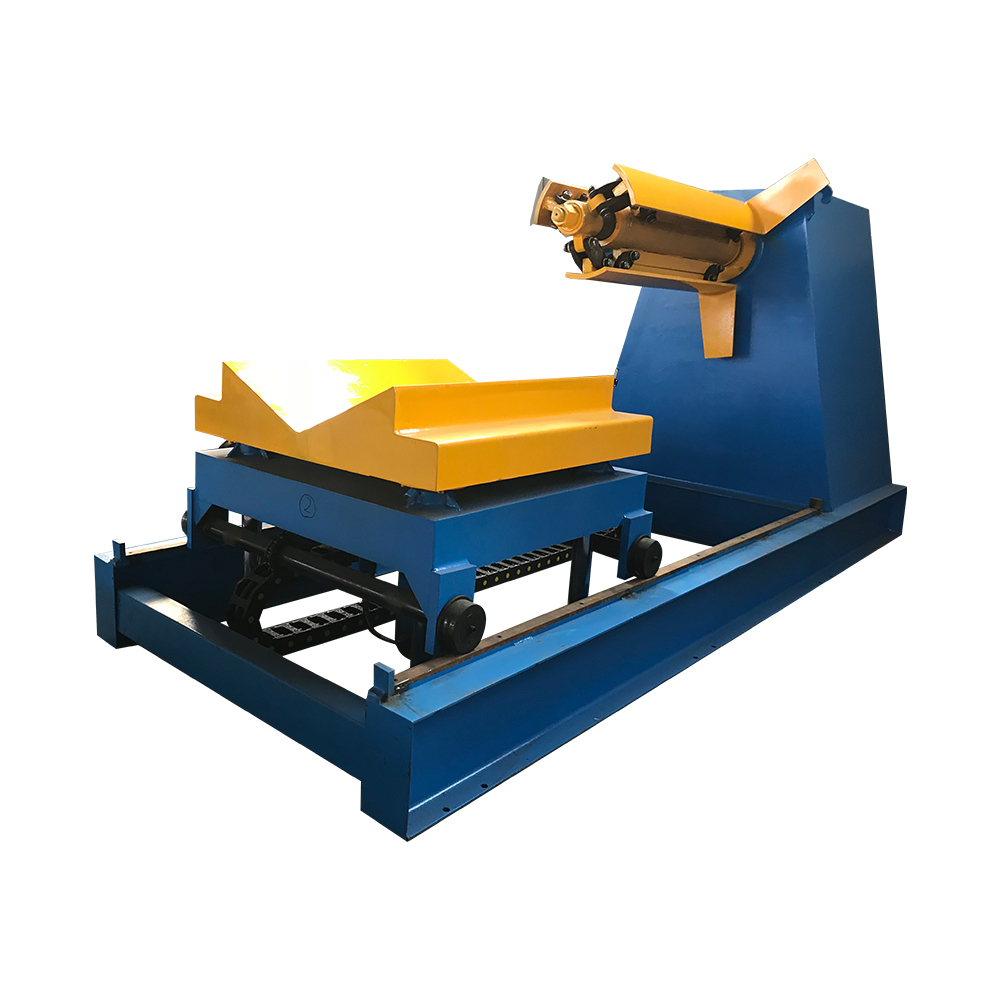

Main components of rain gutter cold roll forming machine:

1. Decoiler————————————1 set

2. Direction guilder————————–1 set

3. Roll Former machine———————1 set

4. Hydraulic cutter—————————1 set

5. PLC controller—————————–1 set

6. Run out tables——————————1set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Design integrating copper cladding | Decoiler In Color Coating Line

Meet China’s mighty skyscraper-building machine | Decoiler In Color Coating Line

High definition Cross T Section Steel Grid Manufacturer - Rain Gutter Cold Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

PriceList for Coil Decoiler - Trapezoidal Roof...

-

professional factory for Telescopic Channel Mac...

-

Low price for Big Structure Roof Steel Machine ...

-

factory low price Steel Structure C Z U Purlin ...

-

Reasonable price for Ceiling T Bar Grids Formin...

-

factory customized Rockwool Foam Sandwich Panel...