Adhering towards the theory of “quality, support, efficiency and growth”, we’ve attained trusts and praises from domestic and international client for High Quality Galvanized Steel Roofing Panel Sheet Electric Shear Ibr Trapezoidal Roll Forming Making Machine With Speed, We are going to do our greatest to meet or exceed customers’ specifications with top quality solutions, advanced concept, and efficient and timely provider. We welcome all prospects.

Adhering towards the theory of “quality, support, efficiency and growth”, we’ve attained trusts and praises from domestic and international client for Galvanized Steel Rollers Machine, Trapezoidal Roofsheet Metlal Rollers Machine, Trapezoidal Trapezoidal Roofsheeting Machine, We’ve been adhering to the philosophy of “attracting customers with the best products and excellent service”. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The trapezoidal tile double roll forming machine adopts high-level automatic control software to realize production information management.

Parameters of double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

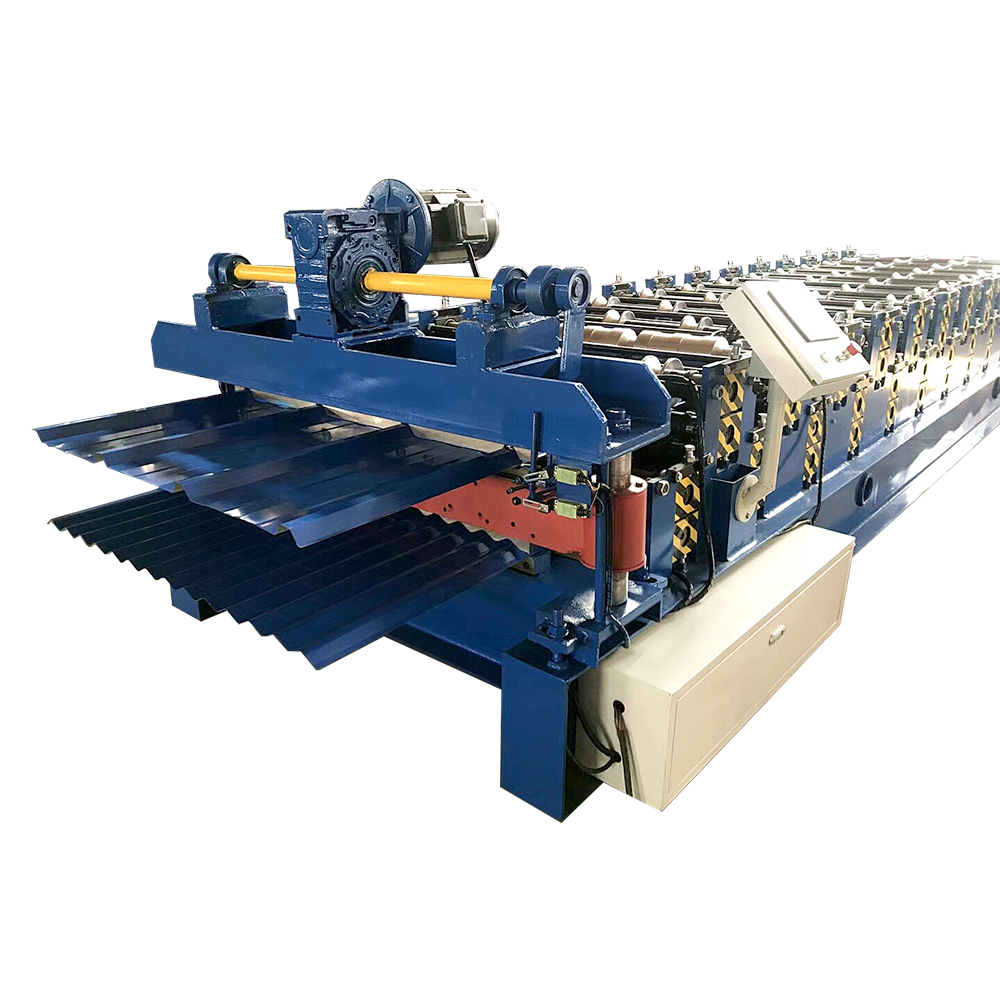

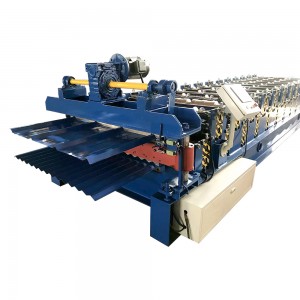

Machine photos

Components of double layer corrugated roof sheet making machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

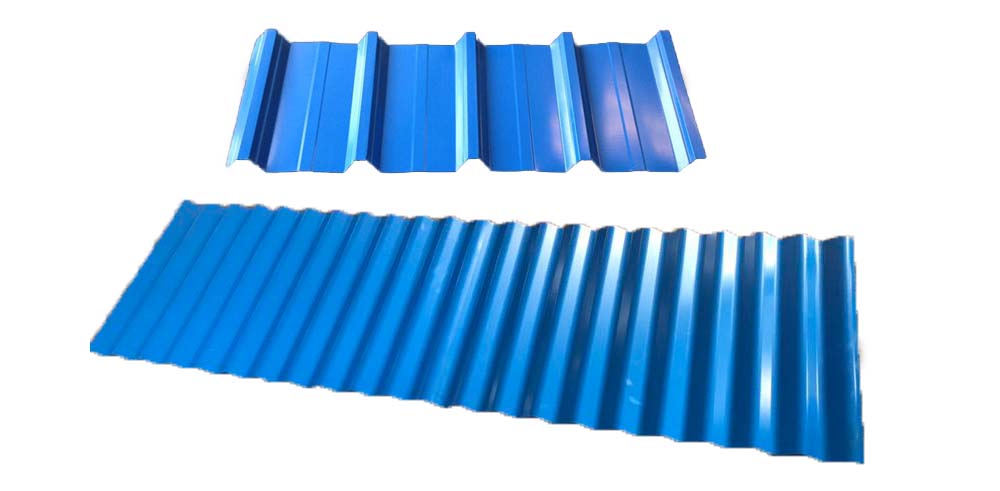

Our company owned professional design team, we can design different profile according customer’s demands.

FAQ

Q:Are you a manufacturer?

A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What’s the delivery time?

A: Normally will take 60 days, for small lines will take 30 days.

Q:Do you have after-sale support?

A:Yes, we’re always here for giving you advice and support for technical details since we have senior technician.

-

Good quality Hebei Color Stone Coated Metal Roo...

-

Lowest Price for Rib Glazing Embossing Metal Ro...

-

Hot sale Ld-1300a Bopp Self Adhesive Tape Slitt...

-

8 Years Exporter Double Layer Ibr Steel Roof Sh...

-

2019 Latest Design Hydraulic Sheet Stainless St...

-

Hot-selling Latest Technology Steel Door Frame ...