New Delivery for Roof Shingles Machine - PU Sandwich Roof Roll Forming Machine – Haixing Industrial Detail:

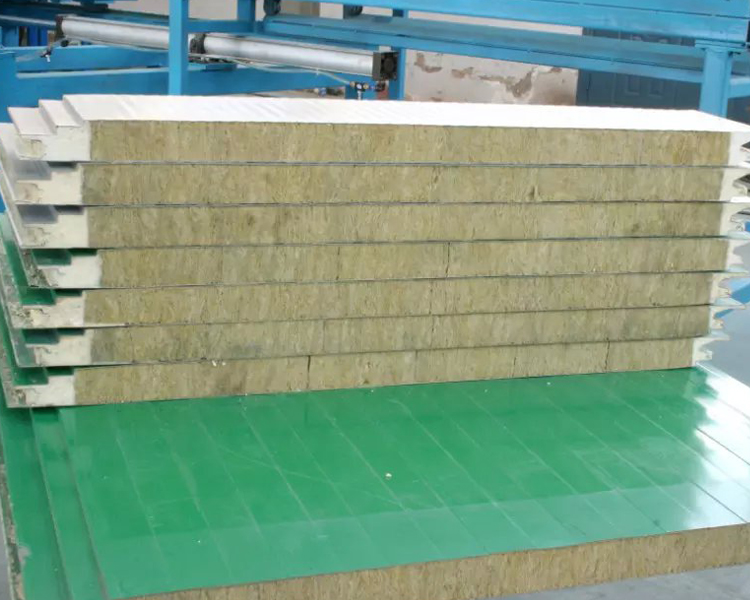

PU Sandwich panel as a kind of construction material is widely used in construction, heat preservation, packaging, frozen, daily necessities, industrial casting, etc.

It can also be used to display the assembly places, commodity cabinet, signs and toys manufacture.

|

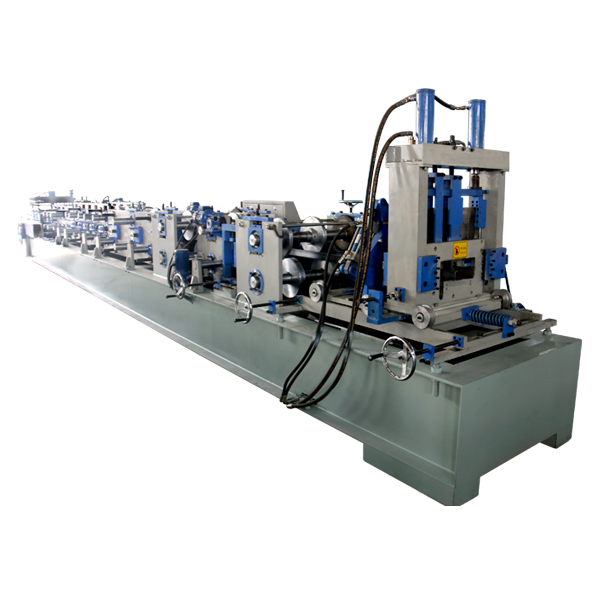

PU Sandwich Roof Roll Forming Machine parameters |

||

|

1 |

Equipment overall dimensions |

30m*2.6m*3m |

|

2 |

Total weight |

About 16 ton |

|

3 |

Control system |

Omron encoder PLC |

|

4 |

Main motor power |

Planetary cycloid reducer, 4kw, 380V, 50HZ |

|

5 |

Processing speed |

4~4.5 m/min, continuous stepless adjusted, variable frequency speed regulation, digital display |

|

6 |

raw material |

1.2 meters |

|

7 |

Voltage |

380V |

|

8 |

Roller material |

chrome plated on 45# steel forgings |

|

9 |

Number of rubber shafts |

27 foams, 39 rock wool |

|

10 |

Total power |

30 kw |

|

11 |

Synchronous controller |

Digital synchronous controller |

|

12 |

Corrugated press motor power |

Double-stage cycloid reducer 4kw, 380V, 50HZ |

|

13 |

Application |

roof panel, wall panel |

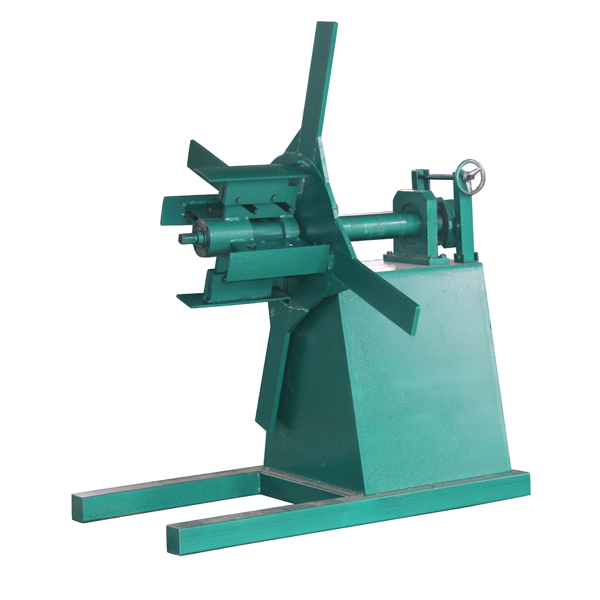

Machine picture display

Packaging and Shipping

1) Tighten the container with a wire rope and weld the container to the container with natural iron.

2) Main forming machine and un-coiler is naked (we can also use waterproof plastic packaging if needed).

3) PLC control system and motor pump are packed in wooden box with water proof paper coverage.

Product detail pictures:

Related Product Guide:

Oden Technologies raises $10M to bring data analytics to manufacturing | Roof Sheet Curving Machine

Studio Morison’s shelter is designed for when nature reclaims the planet | Ibr Roof Sheet Making Machine

New Delivery for Roof Shingles Machine - PU Sandwich Roof Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Leading Manufacturer for C Light Steel Keel Rol...

-

Good quality Aluminum Frame Bending Machine - ...

-

Discount wholesale Roof Tile Manufacturing Mach...

-

Manufacturing Companies for Tile Roof Machine -...

-

Big Discount Metal Arch Roofing Curving Roll Fo...

-

Hot Selling for Roof Making Machine - Corrugat...