“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for OEM/ODM China Latest Technology Roof Making Machine Color Roll Forming Corrugated Steel Iron Crimping Double Layers Flat Sheet Tile Machine, President of our firm, with whole staff, welcomes all consumers to visit our organization and inspect. Allow us to cooperate hand in hand to generate a superior long run.

“Control the standard by the details, show the energy by quality”. Our corporation has strived to establish a hugely efficient and stable workers team and explored an effective high quality control procedure for Corrugated Color Steel Roll Forming Machine Corrugated Steel Crimping Machine Sheets Tile Making Machine, Double Layers Flat Sheet Corrugated Roll Forming Machine, Roof Machine Corrugated Iron Sheet Machine, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of “good quality, reasonable price, the first-class service”. We are willing to build long-term, friendly and mutually beneficial cooperation with you.

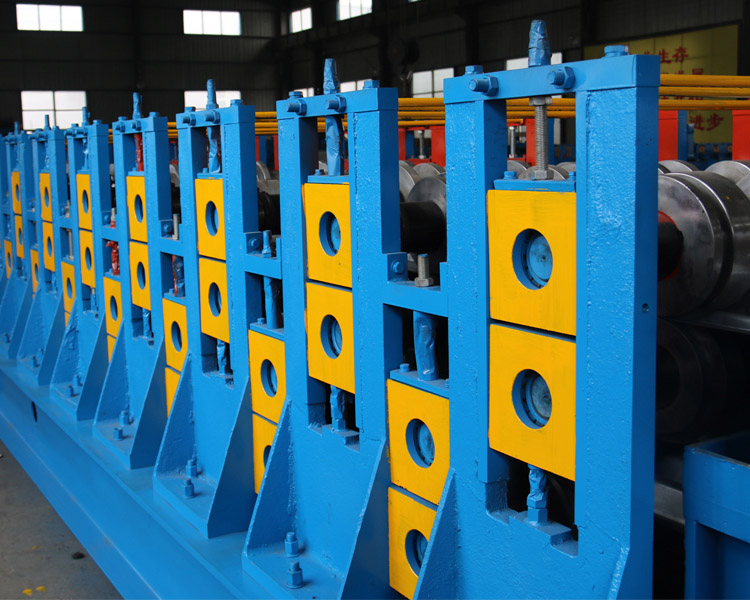

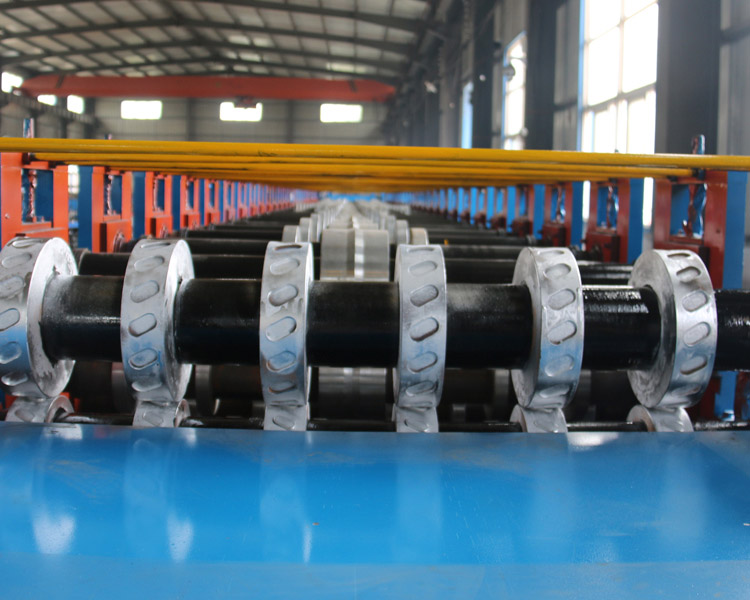

Parameters of steel double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

-

Chinese Professional Standing Seam Self Lock Me...

-

Supply OEM/ODM China Steel Light Keel Plate Rol...

-

2019 China New Design 900 Cold Rolled Steel Ibr...

-

Quality Inspection for Machinery Light Steel Fr...

-

Factory supplied Jcx And Metal Door Frame Cold ...

-

Best quality Sheet Metal Steel Strip Slitting M...