OEM/ODM Manufacturer Arched Roof Panel Forming Machine - Slitting Line Machine – Haixing Industrial Detail:

Slitting machine line cuts the metal coil into strips of various widths required, and then collects the strip into small rolls for use in the next process.

|

Slitting line machine parameters |

||

|

Raw Material (if the material is stainless steel, please tell in advance) |

1 | Material: carbon steel and others |

| 2 | The thickness of the material: 0.4mm-6mm. | |

| 3 | Width: 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm | |

| 4 | Input width: 600-1600mm | |

|

Hydraulic decoiler with car |

1 | The inner size: 450–610mm |

| 2 | The Max width: 1250mm | |

| 3 | The capacity: 15T 20Ton or more | |

|

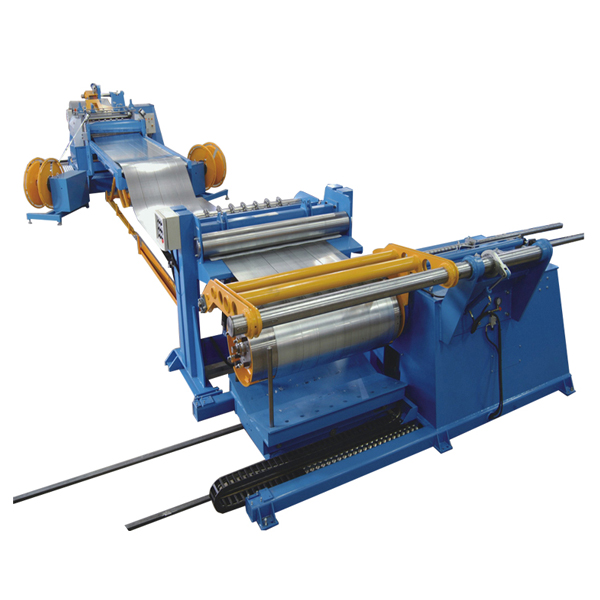

Flatting and Cutting System |

1 | 2 shafts for feeding coil, 9 shafts for flatting |

| 2 | material of flatting: 42CrMo heat treated 50-52. | |

| 3 | hydraulic system. | |

| 4 | 2 sets cutting blade | |

| 5 | width of cutting: 600mm–1220mm. | |

| 6 | the material of blade mould: Gr12MoV | |

| 7 | power: 22KW Motor with ZQ650 Reducer | |

|

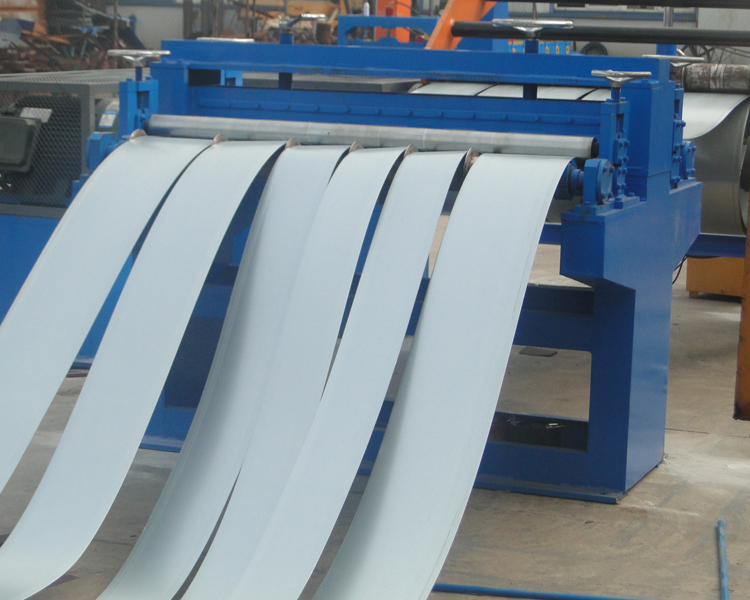

Slitting system |

1 | The width range: 200–1300mm |

| 2 | The precious of the width: ±1mm | |

| 3 | The speed of slitting: 25m/min | |

| 4 | The width can be change. | |

| 5 | Material of the slitting: Cr12MoV. | |

| 6 | Hardness of slitting blade: HRC5860. | |

| 7 | Slitting: 2~3mm 6 lines. | |

| 8 | Quantity of blades: 10 sets. | |

| 9 | Width of side scrap: 3-15mm | |

| 10 | The precious of side scrap: ±0.5mm | |

| 11 | Quantity of side scrap: 2 strips | |

| 12 | Power of the slitting: 37KW, 1000r/min, with ZQ750 Reducer. | |

|

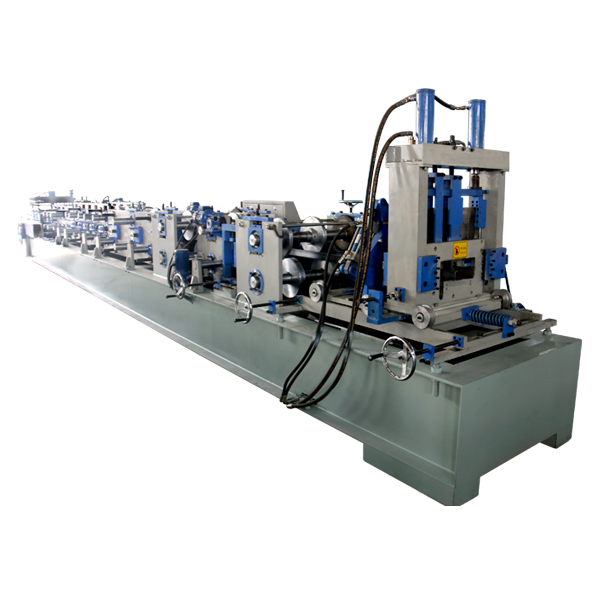

Control System |

1 | Screen: 3.2inch button screen |

| 2 | PLC: Delta | |

|

Electrical collecting machine with car |

1 | Material inner: 550-650mm |

| 2 | Max Coil width: 1500mm | |

| 3 | Carrying capacity: 5T | |

| 4 | Automatic relax or collect | |

| 5 | Power: 22KW | |

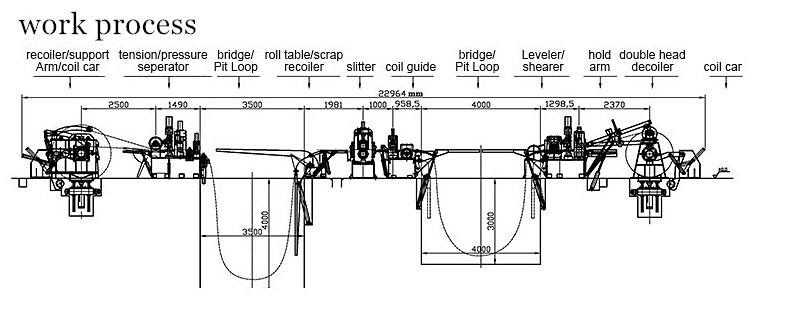

Working process

Decoiler —-flatting and cutting—slitting—–flatting and collecting

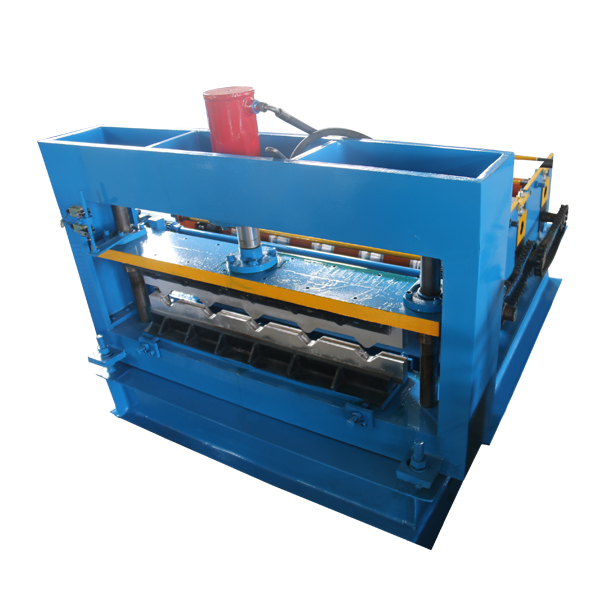

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Product detail pictures:

Related Product Guide:

Specifications for Commercial Skylights | Ibr Roof Sheet Making Machine

Meet China’s mighty skyscraper-building machine | Roof Sheet Curving Machine

OEM/ODM Manufacturer Arched Roof Panel Forming Machine - Slitting Line Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

100% Original Hydraulic Shearing Machine - C Z...

-

Hot-selling Aluminum Decoiler - Color Coated G...

-

Factory supplied Flat Sheet Bending Machine - ...

-

Factory making Metal Steel Decoiler Uncoiler -...

-

Rapid Delivery for Steel Door Frame Easy Buildi...

-

Competitive Price for Metal Stud Runner Roll Fo...