PriceList for Grid T Bar Forming Machinery - Roller Shutter Door Roll Forming Machine – Haixing Industrial Detail:

Machine parameters

|

Roller shutter door roll forming machine |

||

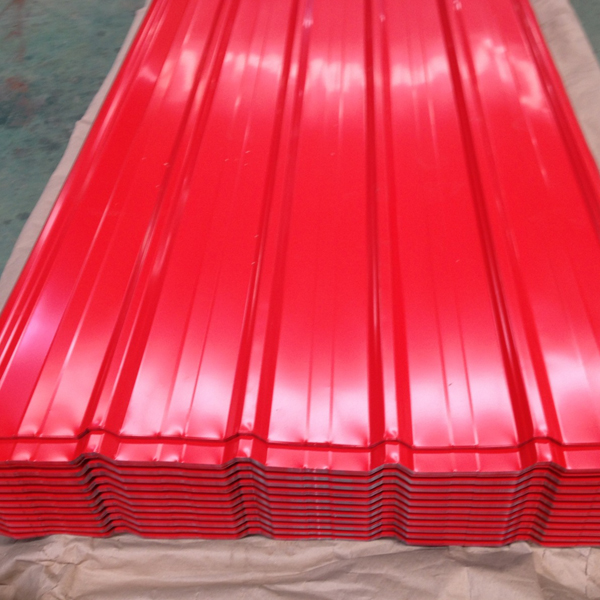

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

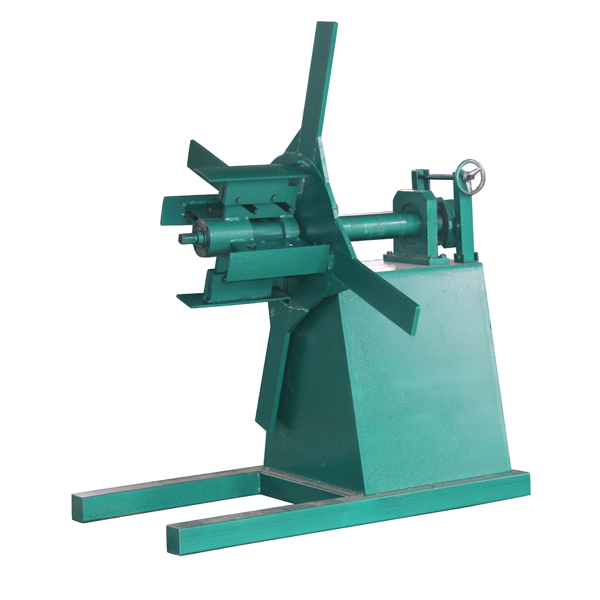

| 9 | Manual uncoiled | Max. Capacity: 3000kgs

Manual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

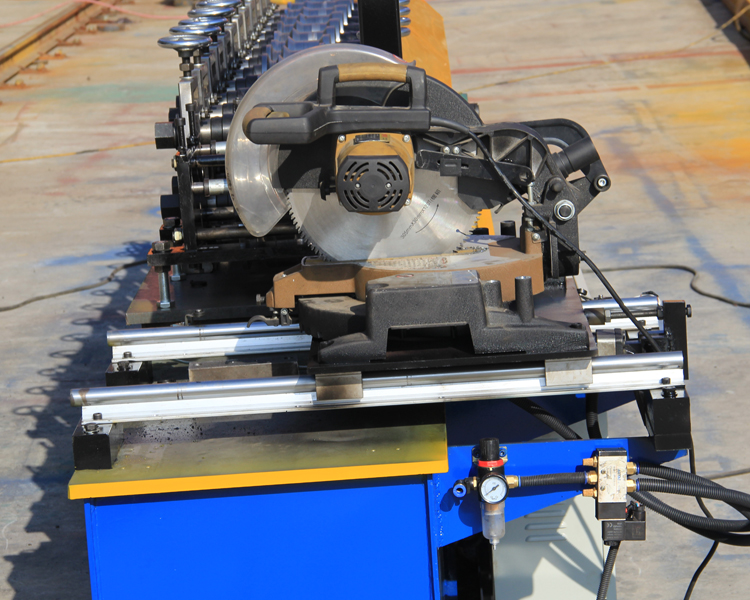

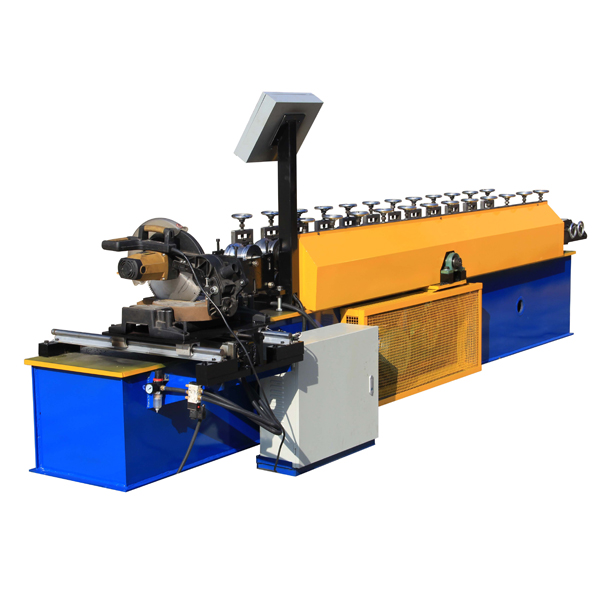

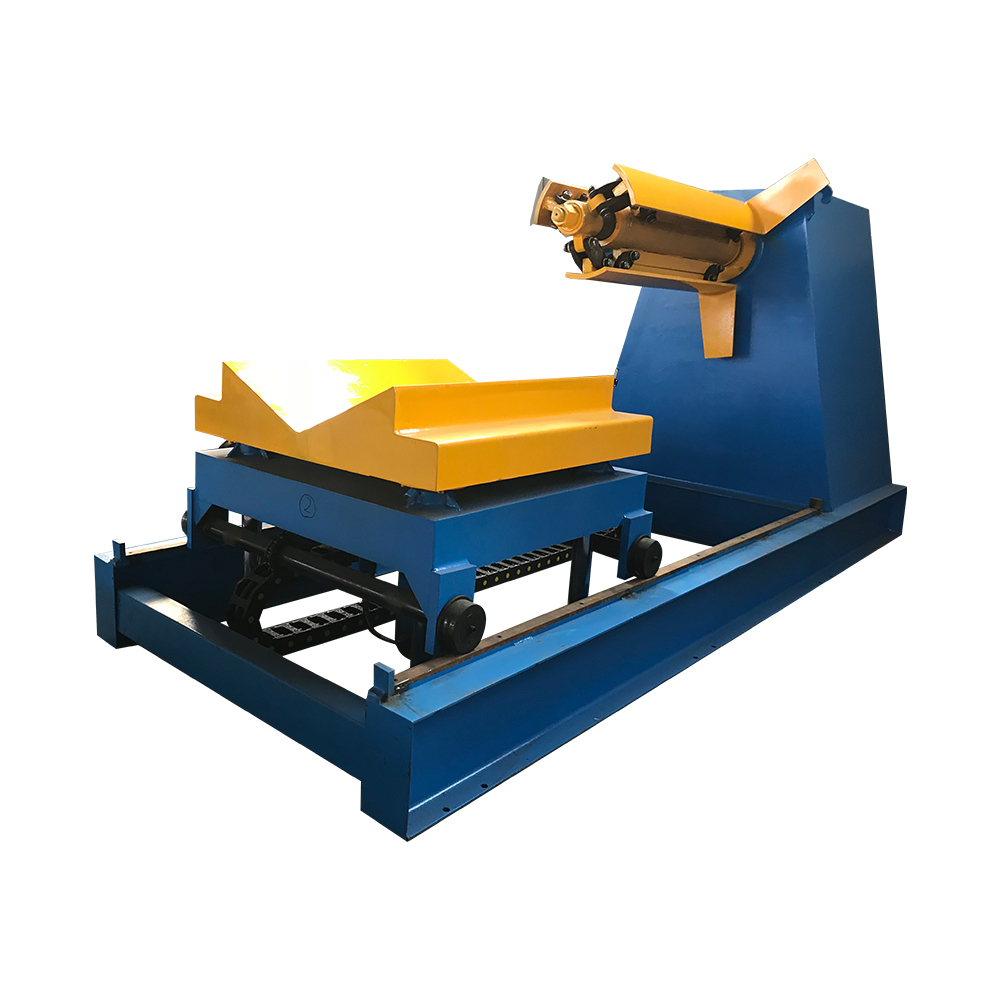

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

Product detail pictures:

Related Product Guide:

Everything You Ever Wanted to Know About Earth’s Past Climates | Science | Ibr Roof Sheet Making Machine

‘She makes children of us all’: Guardian writers pick their favourite Kate Bush lyrics | Music | Ibr Roof Sheet Making Machine

PriceList for Grid T Bar Forming Machinery - Roller Shutter Door Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Fixed Competitive Price Metal Stud And Track Ro...

-

Bottom price T Grid Roll Forming Machinery - D...

-

Fixed Competitive Price Downspout Gutter Making...

-

Factory made hot-sale Floor Decking Sheet Roll ...

-

Factory For Metal Coil Decoil - Corrugated Roo...

-

One of Hottest for Used Metal Sheet Rolling Mac...