Inside the past few years, our business absorbed and digested advanced technologies equally at home and abroad. Meanwhile, our corporation staffs a workforce of experts devoted to your progress of Professional China Galvanized Metal Sheet Square Downspout Pipe Roll Forming Machine, We, with fantastic passion and faithfulness, are willing to offer you with best services and striding forward with you to make a bright foreseeable future.

Inside the past few years, our business absorbed and digested advanced technologies equally at home and abroad. Meanwhile, our corporation staffs a workforce of experts devoted to your progress of Downspout Pipe Roll Forming Machine, Galvanized Metal Sheet Square Downspout Pipe Roll Forming Machine, Square Pipe Making Machine, We are confident that we’re able to offer you with opportunities and might be a valuable business partner of you. We look forward to working with you soon. Learn more about the types of goods that we work with or contact us now directly with your inquiries. You are welcome to contact us anytime!

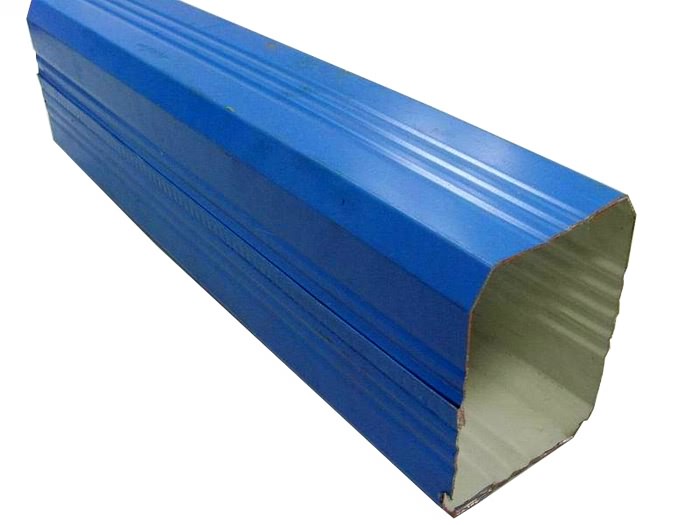

The downspout cold roll forming machine is used to manufacture metal pipes that collect roof rainwater and concentrate them on rainwater pipes below the ground.

|

Downspout roll forming machine parameters |

||

| 1 | Material specifications | color-painted galvanized steel sheet |

| 2 | Thickness | 0.40mm to 0.60mm |

| 3 | Main motor power | 7.5kW |

| 4 | Hydraulic station power | 4kW |

| 5 | Feeding width | up to the final design |

| 6 | Cover width | up to the final design |

| 7 | Coil yield strength | Q235MPa (33KSI) |

| 8 | Roll forming speed | 10-12m/min |

| 9 | Cutting tolerance | ±2mm |

| 10 | Rollers material | no 45 steel coated with chrome |

| 11 | Cutting blades material | Cr12 mold steel |

| 12 | Manual decoiler Max capacity | 3000kg |

| 13 | Type of cutting | roll-formed and length-set cutting |

| 14 | Control system | Mitsubishi PLC, inverter and touchscreen |

| 15 | Encoder | Omron |

Main components of Downspout cold roll forming machine:

Decoiler: 1 set

Sheet gilding device: 1 set

Roll former: 1 set

Hydraulic cutting device: 1 set

PLC control system: 1 set

Supports tables: 1 set

Downspout curving machine: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Cheapest Price 6-8 Pieces Per Minute Roof Tile ...

-

Competitive Price for China Kexinda Stoving Var...

-

Chinese Professional Aluminium Corrugated Metal...

-

OEM Factory for Galvanized Steel Sheet Floor De...

-

Competitive Price for Ce Certificate 3mm Sheet ...

-

Fast delivery China Ce Certification Double Lay...