Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for Professional Factory for Popular Sheet Metal Roof Roll Former Roof Tile Making Machine Ibr Trapezoidal Roll Forming Machine Made In Botou City, We will do our best to meet your requirements and are sincerely looking forward to developing mutual beneficial business relationship with you!

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for Tile Iron Roof Sheet Roll Forming Making Machine, Trapezoidal Different Panel, Trapezoidal Roll Forming Machine, We attained ISO9001 which provides solid foundation for our further development. Persisting in “High quality, Prompt Delivery, Competitive Price”, we have established long-term cooperation with clients from both overseas and domestically and get new and old clients’ high comments. It is our great honor to meet your demands. We’re sincerely expecting your attention.

We have a variety of machinery and production methods to meet the growing needs of our customers. Our different types of roll forming operations are simple and efficient.

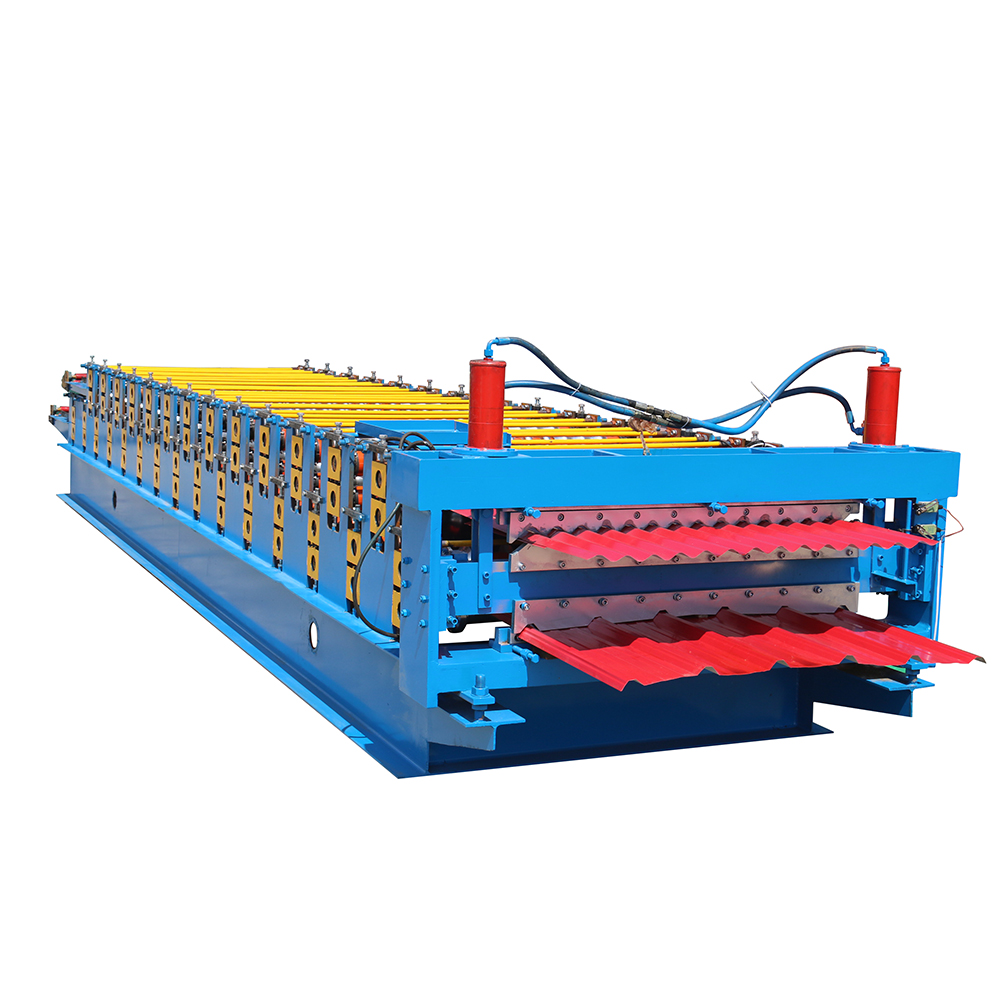

Parameters of double layer corrugated roof sheet making machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

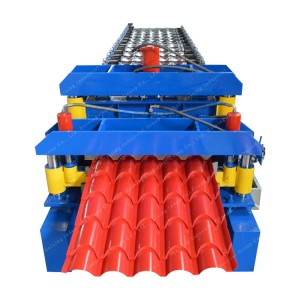

Machine photos

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our machine’s packaging:

1.Main roll forming machine package by Plastic film;

2.Main machine spare parts package by paper box;

3.We have professional technicians for loading, guaranteed the goods load into container without any damage.