That has a positive and progressive attitude to customer’s fascination, our enterprise constantly improves our merchandise high quality to meet the demands of customers and further focuses on safety, reliability, environmental requirements, and innovation of Rapid Delivery for Trapezoidal Plate Roof Roll Sheet Corrugated Making Forming Machine, We’ve been searching ahead to building positive and helpful links with all the providers within the planet. We warmly welcome you to definitely get in touch with us to begin discussions on how we are able to bring this into being.

That has a positive and progressive attitude to customer’s fascination, our enterprise constantly improves our merchandise high quality to meet the demands of customers and further focuses on safety, reliability, environmental requirements, and innovation of Colorbond Roof Roll Forming Machine, Corrugated Roofing Sheet Machine India, Trapezoidal Plate Ibr Roof Sheet Corrugated Making Machine, We have more than 8 years of experience in this industry and have a good reputation in this field. Our solutions have won praise from customers worldwide. Our aim is to help customers realize their goals. We have been making great efforts to achieve this win-win situation and sincerely welcome you to join us.

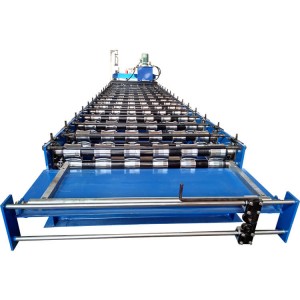

The trapezoidal roll forming machine has the advantages of operation, maintenance, maintenance, mechanical adjustment, and easy mold replacement.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Our Service Advantage

PLC: Ensuring high accuracy and easy to operate!

Full Automatic: Just input length of the sheets and numbers of the piece you need, then start the machine.