Reliable Supplier Cutting And Bending Machine - metal ridge cap roll forming machine – Haixing Industrial Detail:

|

metal ridge cap roll forming machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

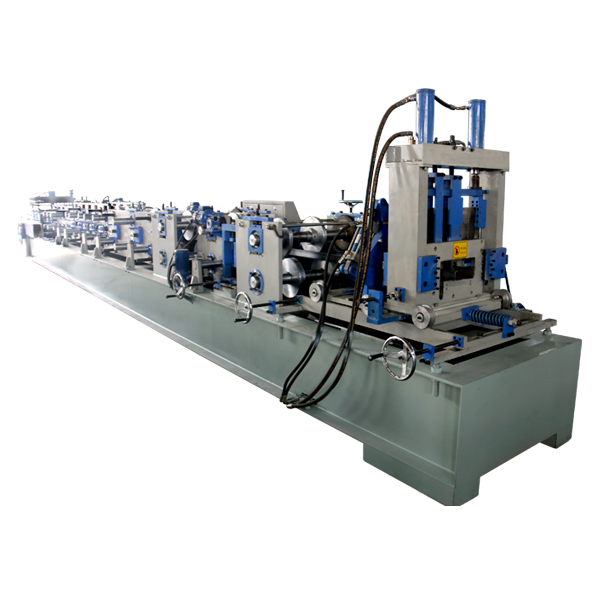

Components of metal ridge cap roll forming machine

1. Manual Decoiler…………………………………………….1 set

2. Feeding Guide……………………………………………….1 set

3. Main Roll Forming Machine……………………………1 set

4. Hydraulic Cutting Device………………………………..1 set

5. Hydraulic Station…………………………………………..1 set

6. PLC Computer Control…………………………………..1 set

7. Output Table…………………………………………………1 set

Machine details:

Package and shipment details:

The machines sold by Haixing Industrial Group Co., Ltd. use standard export packaging, as follows:

1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

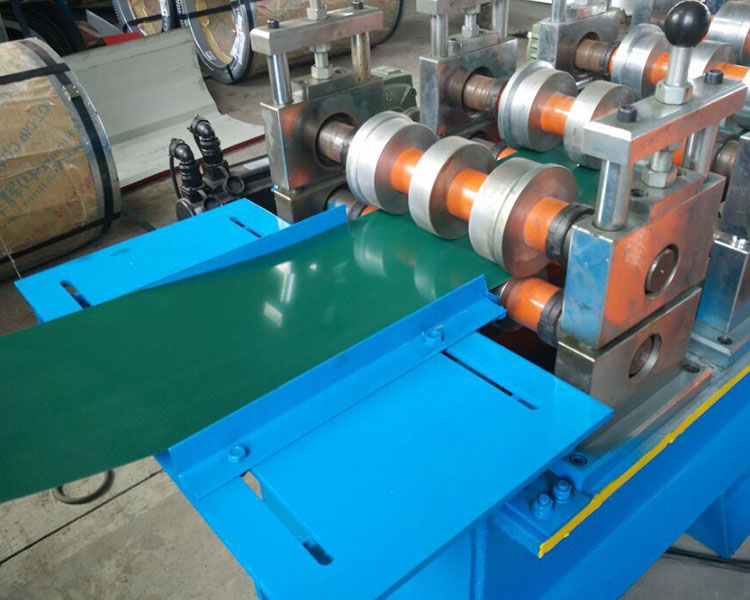

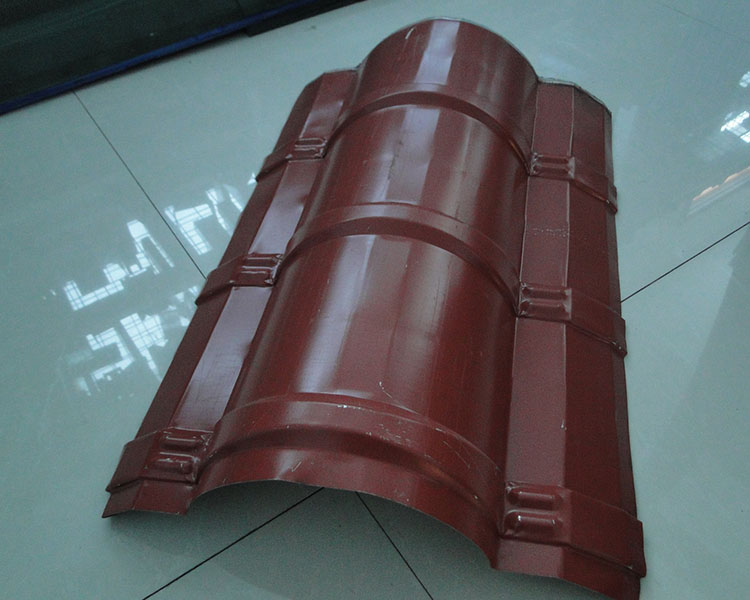

Product detail pictures:

Related Product Guide:

Springfield company begins making tape for cassettes | Roof Sheet Curving Machine

Photos: PHOTOS: Today in History, December 27 – MetroWest Daily News, Framingham, MA | Floor Deck Macking Machine

Reliable Supplier Cutting And Bending Machine - metal ridge cap roll forming machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Reliable Supplier Purlin Roll Forming Machine S...

-

China wholesale Hand Aluminum Profile Bending M...

-

2017 New Style Clean 2 Arms Fume Extractor - C...

-

Europe style for Cnc Bending Machine - Standin...

-

100% Original Factory Metal Stud And Track Mach...

-

Manufacturer for Ibr Floor Deck Panel Sheet Man...