Renewable Design for Downspout Cold Roller Forming Machines - Glazed Roof Panel Roll Forming Machine – Haixing Industrial Detail:

Glazed roof sheets made of glazed roof panel roll forming machines have the characteristics of light weight, high strength and durability.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

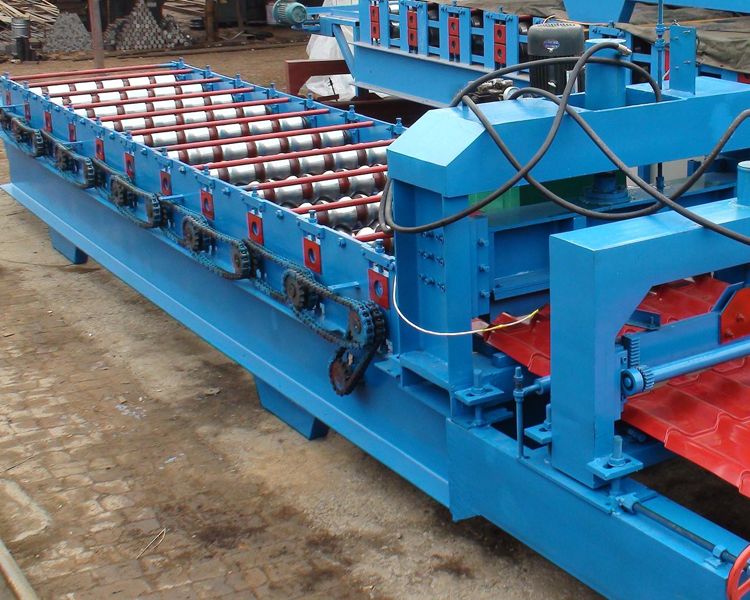

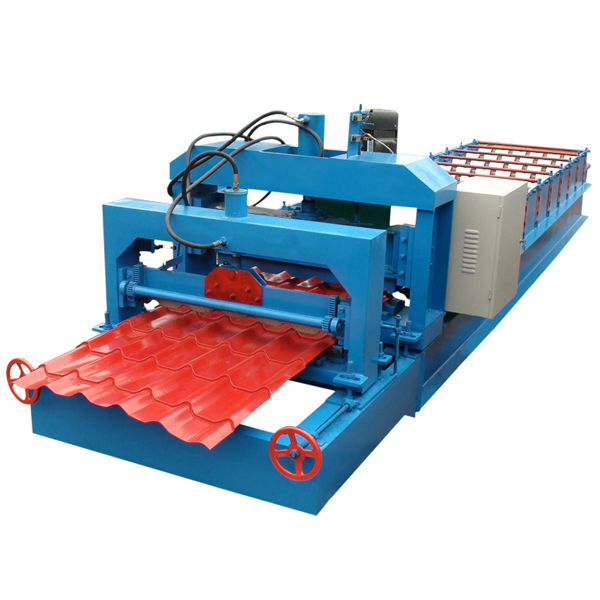

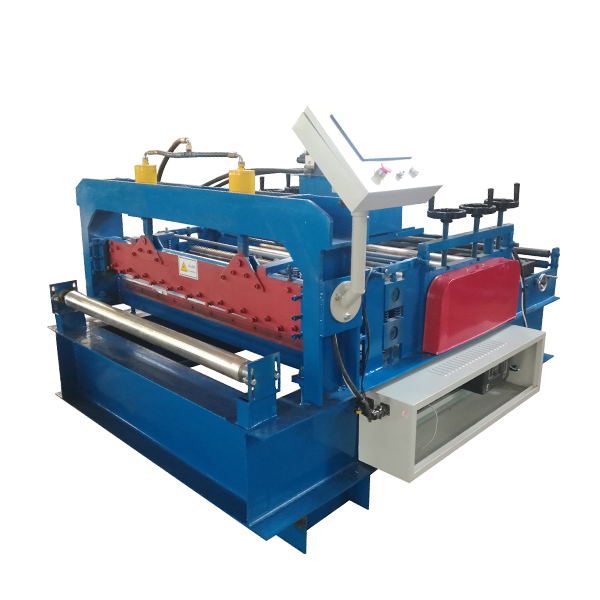

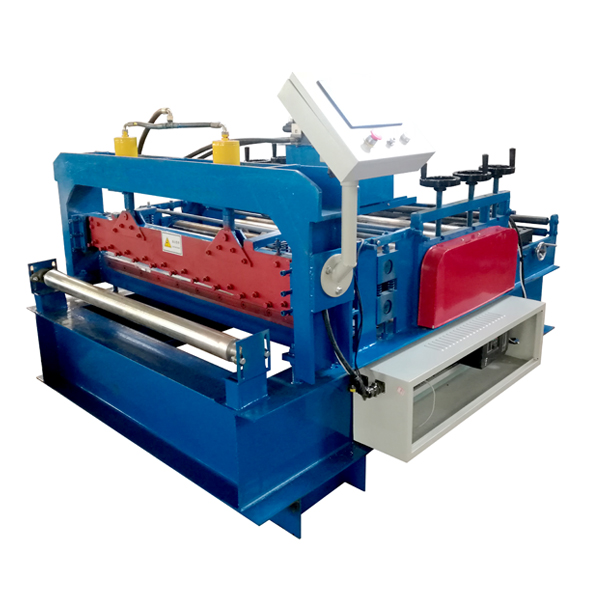

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Get a Sneak Peek Behind the Plywood and Wrap at Seattle’s Space Needle Remodel | Roof Sheet Curving Machine

Get a Sneak Peek Behind the Plywood and Wrap at Seattle’s Space Needle Remodel | Floor Deck Macking Machine

Renewable Design for Downspout Cold Roller Forming Machines - Glazed Roof Panel Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Top Suppliers Sheet Slitting Machine - Sheet C...

-

Hot-selling Aluminum Decoiler - Color Coated G...

-

Manufacturer of Metal Sheets Leveling Machine -...

-

Chinese Professional Steel Roof Crimping Curvin...

-

Hot Sale for Crimp Curving Machine - Floor Dec...

-

Low MOQ for Pur-Air Fume Extractor - Rock Wool...