It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for Top Suppliers Roofing Steel Glazed Roof Tile Making Machine, “Making the Products and solutions of Large Quality” may be the everlasting aim of our organization. We make unremitting efforts to recognize the intention of “We Will Always Keep in Pace with all the Time”.

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for Roof Tile Making Machine, Roofing Steel Making Machine, Steel Roof Tile Making Machine, To get more information about us as well as see all our products and solutions, you should visit our website. To get more information you should feel free to let us know. Thank you very much and wish your business always be great!

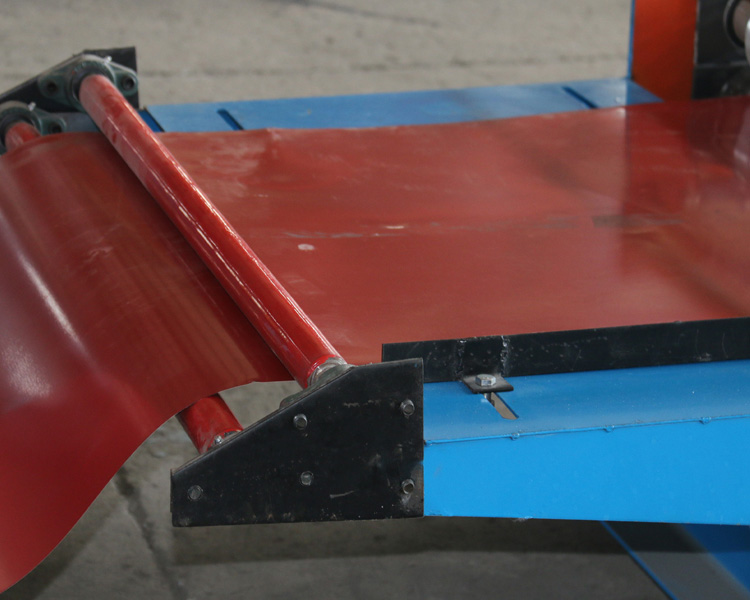

The tiles pressed out by the glazed roofing tile roll forming machine are very beautiful, and the technical parameters of the machine are as follows:

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Glazed roofing tile roll forming machine components include: Manual un-coiler, Guiding platform, Coil strip leveler, Main machine of roll forming, Electric-motor, Cutting device, Hydraulic station, PLC control and Supporter table.

Machine Details:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Quality Inspection for Machinery Light Steel Fr...

-

Personlized Products Metal Steel Split Joint Do...

-

High reputation Aluminum Zinc Plate Colorful St...

-

Good Wholesale Vendors Polystyrene Foam Sheet M...

-

18 Years Factory Automatic Roller Shutter Door ...

-

Ordinary Discount Color Steel Sheet Roofing Sto...