Persisting in “High quality, Prompt Delivery, Competitive Price”, we have established long-term cooperation with clients from both overseas and domestically and get new and old clients’ high comments for Wholesale OEM Steel Ridge Cap Machine, We are searching ahead to cooperating with all buyers from at your home and overseas. Moreover, customer satisfaction is our everlasting pursuit.

Persisting in “High quality, Prompt Delivery, Competitive Price”, we have established long-term cooperation with clients from both overseas and domestically and get new and old clients’ high comments for Ridge Cap, Ridge Cap Machine, Ridge Cap Roll Forming Machine, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality solutions and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

|

roof ridge making machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

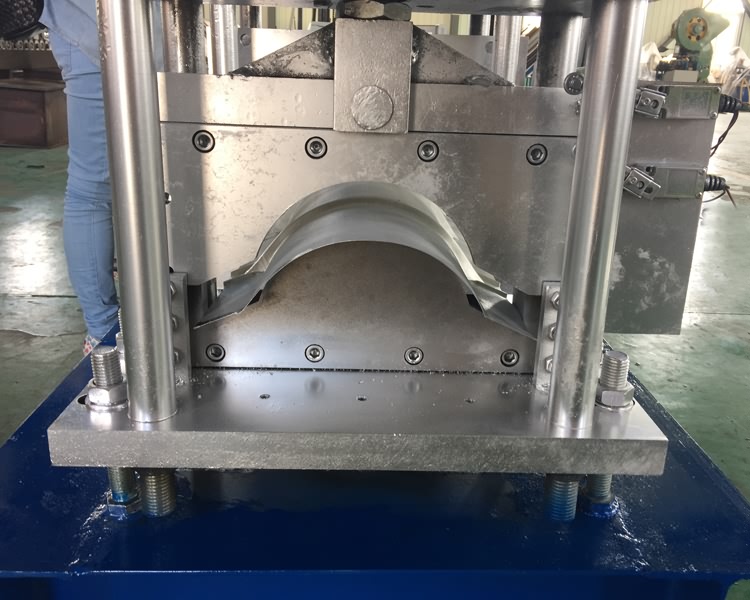

Machine details:

Roof ridge making machine package and shipment details:

Standard export packing: 1 x 40GP container, main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

-

Free sample for China Automatic Movable Standin...

-

Reasonable price Roller Shutter Door Roll Formi...

-

Chinese wholesale Double Layer Cold Roll Steel ...

-

Supply ODM Australia Steel Roller Shutter Door ...

-

OEM Factory for Customized Design Ridge Tiles /...

-

Factory directly Sanxing China KR 163 Standing ...