18 Years Factory Roller Shutter Door Frame Cold Roll Forming Machine - Roofing Ridge Cap Machine – Haixing Industrial Detail:

|

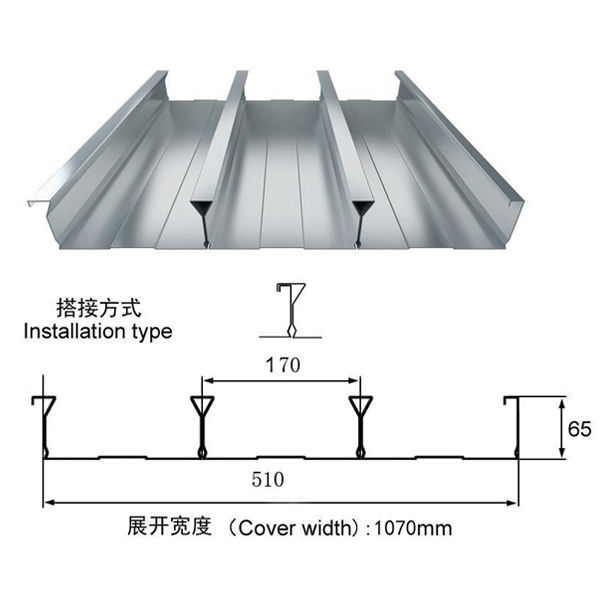

roof ridge making machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate. Besides, we can make and design will kinds of roll forming machine according to customer’s request.

Machine details:

Roofing ridge cap machine package and shipment details:

Standard export packing: 1 x 40GP container, main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

Sales Service:

1.we provide the technical support for whole life of our machines.

2.If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost ,including visa, round trip ticket etc.

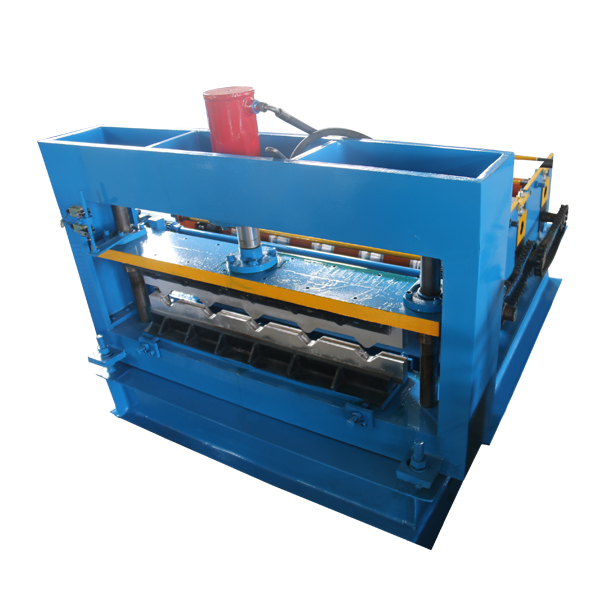

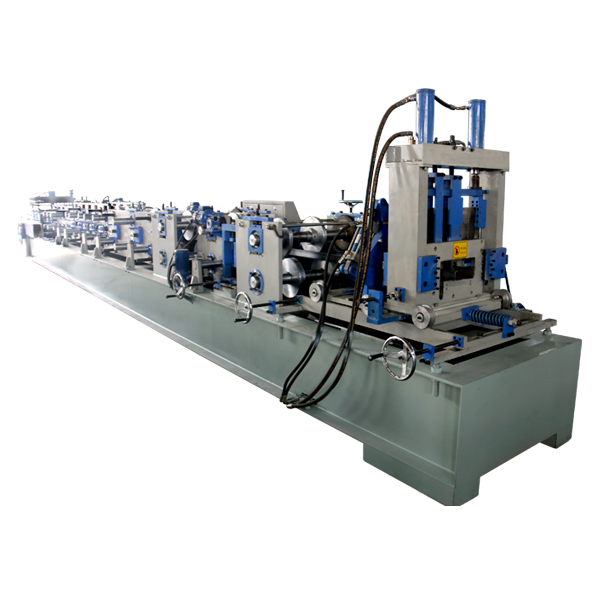

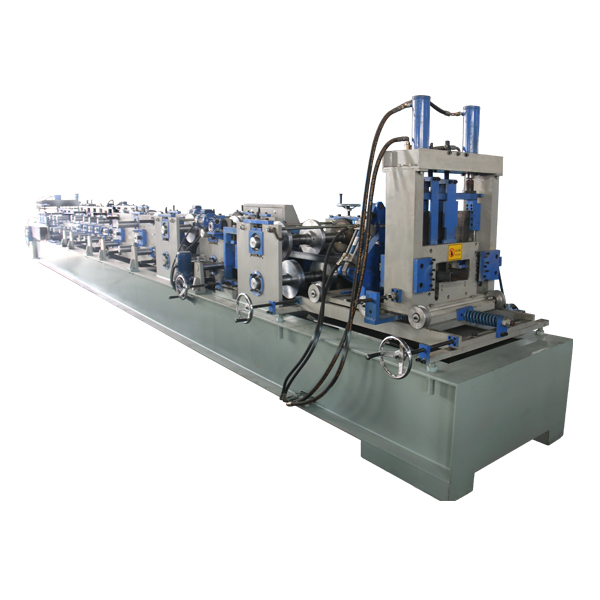

Product detail pictures:

Related Product Guide:

Architects’ cutting knife ErgoKiwi alleviates “unbearable” hand cramps | Roof Sheet Curving Machine

Of Christmas, men’s stores and tape decks: Missoula 1968 | Local | Steel Downpipe Roll Forming Machine

18 Years Factory Roller Shutter Door Frame Cold Roll Forming Machine - Roofing Ridge Cap Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Hot Sale for Trapezoidal Sheet Roll Forming Mac...

-

2017 Latest Design Main Tee Cross Tee And Wall ...

-

2017 China New Design Z Purlins Cold Roll Formi...

-

Free sample for Bending And Cutting Machine - ...

-

New Arrival China Stone Steel Roof Tile Machine...

-

OEM/ODM China Sheet Metal Cutting - Automatic ...