Factory source Tile Moulding Machine - Galvanized Ridge Cap Zinc Roofing Sheet Roll Forming Machine – Haixing Industrial Detail:

|

galvanized ridge cap zinc roofing sheet roll forming machine parameters |

||

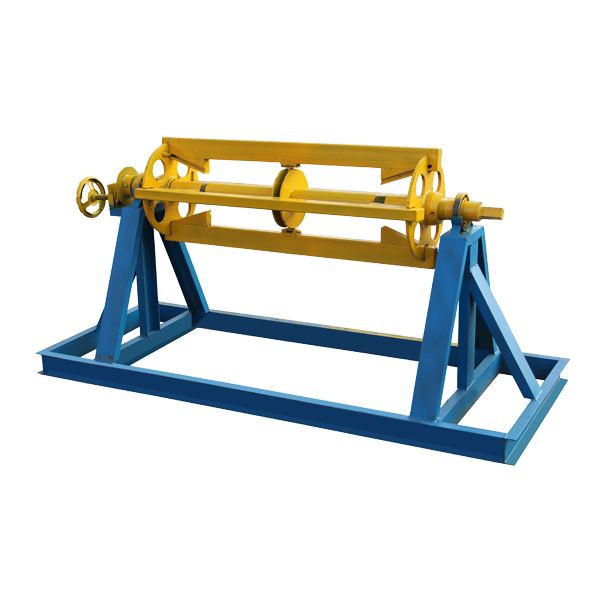

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

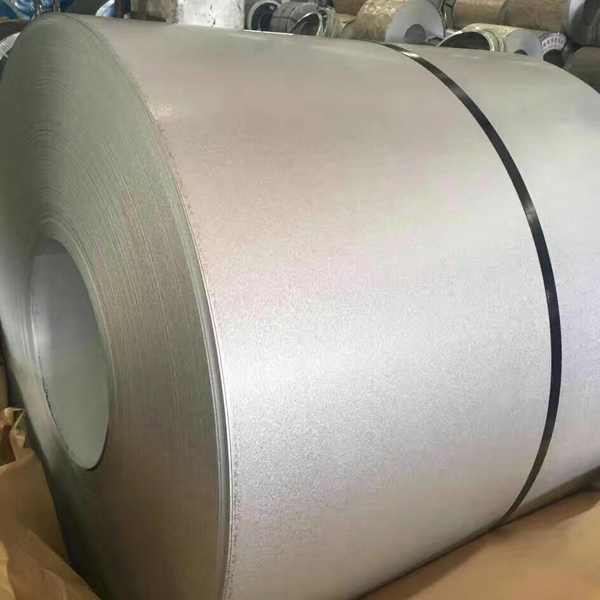

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

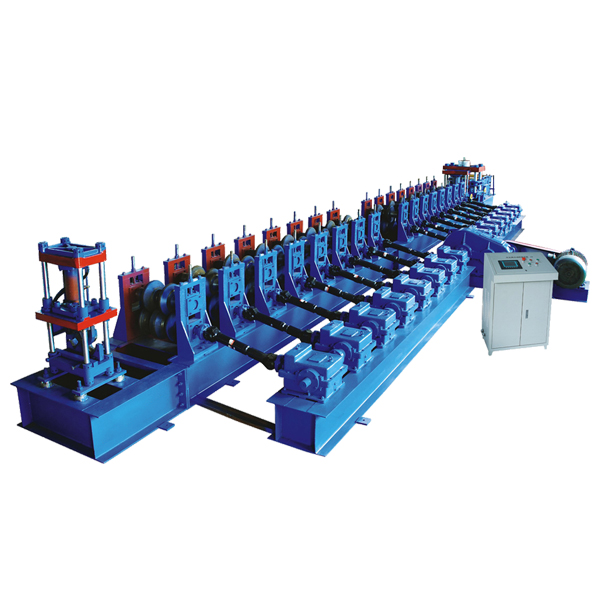

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

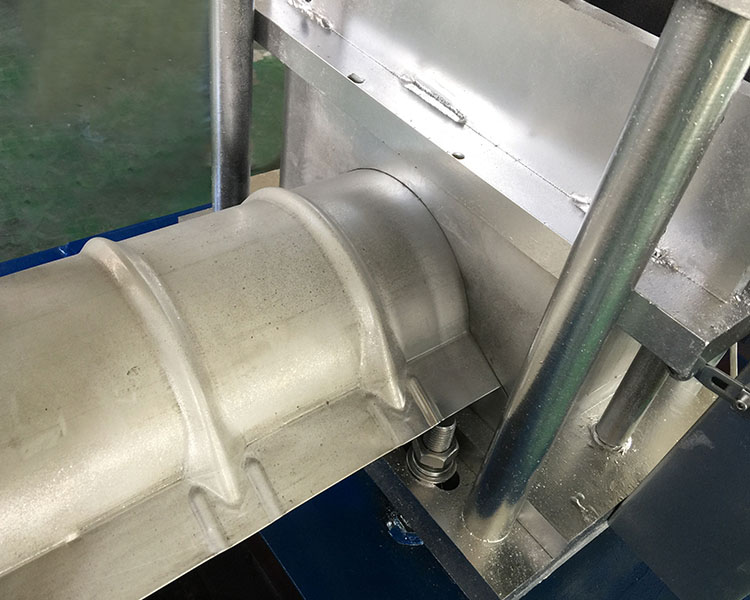

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

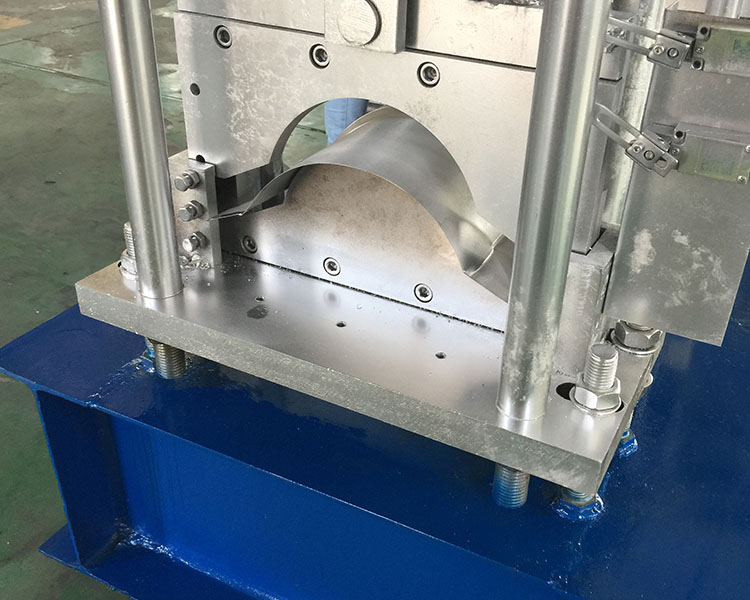

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

Galvanized ridge cap zinc roofing sheet roll forming machine details:

The advantages of the ridge cap roll forming machine

1.Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2.Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable,maintenance-free.

3.We can make and design will kinds of roll forming machine according to customer’s request.

Product detail pictures:

Related Product Guide:

GLORY DAYS: 101 great Hunter moments | Ibr Roof Sheet Making Machine

How to Build a DIY Savonius Wind Turbine | Floor Deck Macking Machine

Factory source Tile Moulding Machine - Galvanized Ridge Cap Zinc Roofing Sheet Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

High Performance Shutter Door Slat Roll Forming...

-

Cheapest Price Roll Forming Machine Roof Sheet ...

-

Hot sale Metal Roof Panel Roll Forming Machine ...

-

2017 Latest Design Rain Gutter Sheet Forming Ma...

-

Hot-selling Metal Gutter Making Machine - Manu...

-

Good Quality Roofing Curve Machine - 8 Years E...