We pursue the administration tenet of “Quality is exceptional, Provider is supreme, Name is first”, and will sincerely create and share success with all clientele for High Quality Corrugated Roof Sheet Making Machine, We sincerely welcome domestic and foreign retailers who phone calls, letters asking, or to plants to barter, we’ll supply you excellent products and solutions plus the most enthusiastic provider,We look ahead on your check out as well as your cooperation.

We pursue the administration tenet of “Quality is exceptional, Provider is supreme, Name is first”, and will sincerely create and share success with all clientele for Corrugated Roof Sheet Making Machine, Roof Sheet Making, Roof Sheet Making Machine, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they’re created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

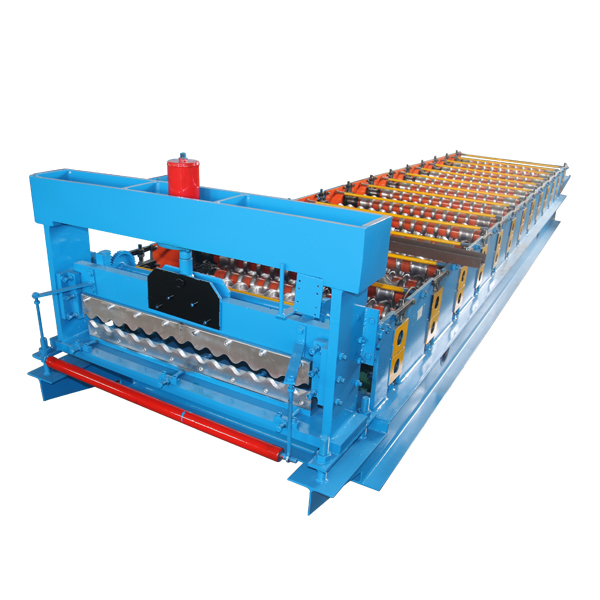

Parameters of corrugated metal roofing sheet machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Photos:

If you have any questions about the model, parameters, etc., please feel free to contact us. We will do our best to answer your questions and look forward to cooperation.

-

China Manufacturer for 2 To 6m Metal Sheet Bend...

-

Quots for China Metal Sheet Coil Straightening ...

-

Factory Free sample Hydraulic Trapezoidal Used ...

-

OEM China Heat Treatment Cutter Roof Panel Tile...

-

Hot New Products Light Steel Keel Ceiling Fitti...

-

2019 High quality Single Layer Colored Steel Me...