With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for OEM Manufacturer Best Double Layer Corrugated Roof Sheet Forming Machine For Tile Making, By way of more than 8 years of business, we’ve got accumulated rich experience and advanced technologies while in the generation of our items.

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for Double Layer Roll Forming Machine, Double Roofing Sheet Roll Forming Machine, Roof Sheet Forming Machine, Good quality and reasonable price have brought us stable customers and high reputation. Providing ‘Quality Solutions, Excellent Service, Competitive Prices and Prompt Delivery’, we’re now looking forward to even greater cooperation with overseas customers based on mutual benefits. We are going to work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

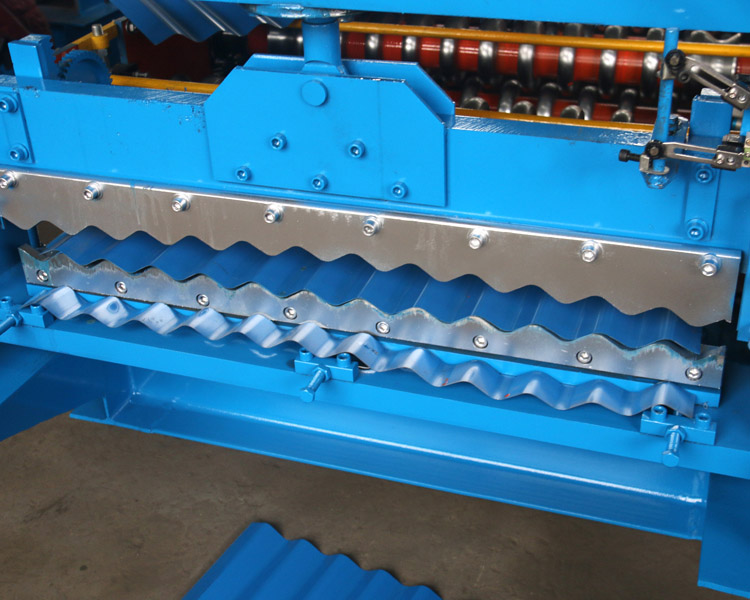

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Factory Supply China 312 Ridge Cap Forming Machine

-

2018 Latest Design Omega Profile Roll Forming M...

-

Factory source Automatic Sheet Metal Bending Ma...

-

Manufacturer for Liming Brand Best Selling Roll...

-

Cheap price Metal C Shape Furred Ceil Studs Tra...

-

Wholesale OEM China Shutter Door Channel Guide ...