Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers’ demands for Super Lowest Price Building Material Color Coated Steel Curving Roof Ridge Cap Panel Forming Machine, On account of superior excellent and aggressive rate , we will be the sector leader, make sure you don’t hesitate to contact us by cellular phone or email, if you’re fascinated in almost any of our items.

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers’ demands for Ridge Cap Roll Forming Machine, Roof Ridge Tiles Machine, Steel Curving Roof Ridge Cap Panel Forming Machine, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

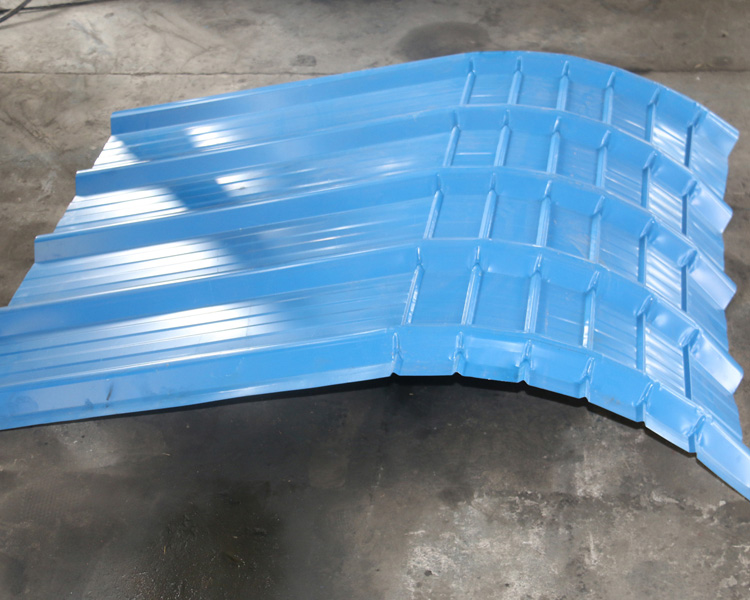

Application of Curved Roof Panel Roll Forming Machine

For architecture: making roof panel, wall panel, ceiling panel, etc.

For Industry: making refrigerating room panel, automobile panel, electric appliance housing, etc.

|

Curved Roof Panel Roll Forming Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

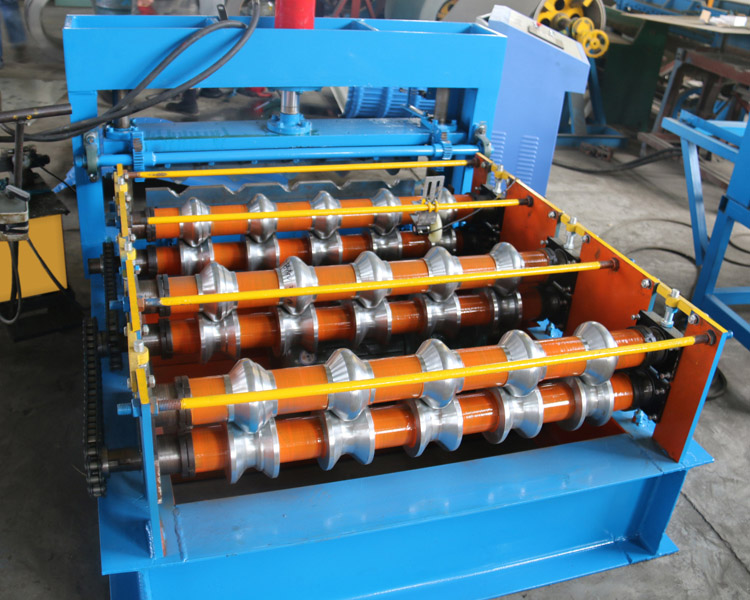

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

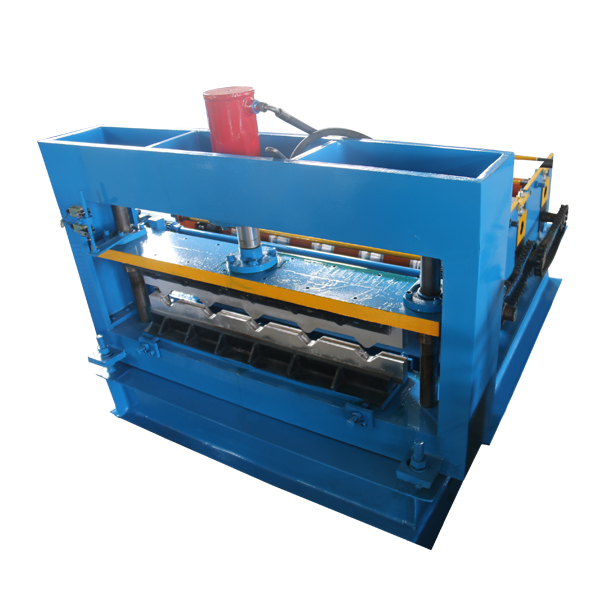

Machine Photos:

Package and shipment details:

1. Main roll forming machine package by plastic film

2. Main machine spare parts package by paper box

3. We have a professional technician load to ensure that the goods are loaded into the container without any damage.

4. Transportation: machines need one 20 feet container to hold.

5. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.