Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for 18 Years Factory Steel Galvanized C Purlin Rool Forming Machine/steel Hot Rolled C Channel Profiles, We welcome buyers, organization associations and mates from all pieces of the entire world to call us and seek cooperation for mutual gains.

Dedicated to strict top quality command and considerate purchaser support, our experienced staff customers are always available to discuss your necessities and be certain full client gratification for Automatic Profile Rolling Machine, C Z Purlin Roll Forming Machine, Steel Profile Making Machine, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our items or have an OEM order to fulfill, remember to feel free to contact us now. Working with us will save you money and time.

|

Steel profile door frame roll forming machine parameters |

||

| 1 | Material width | 3 sizes. Waiting for buyer exactly profile |

| 2 | How to adjust size | Option : by PLC (It can be adjust by PLC and also in hand wheel) One side fixed and the other is adjustable by manual or PLC |

| 3 | Base frame | base frame 30 mm thick steel plate process the surface on CNC planer to keep it leveling and drill bolts and key slot by CNC |

| 4 | Rolling Speed | 12-15m/min(not include cutting time) |

| 5 | Rolling Thickness | 1.2-2.0mm |

| 6 | Material | GI or metal |

| 7 | Control System | PLC (Panasonic) as list in the note |

| 8 | decoiler | 3 Ton manual decoiler |

| 9 | Leveling | Up in 3 roller, down in 4 roller |

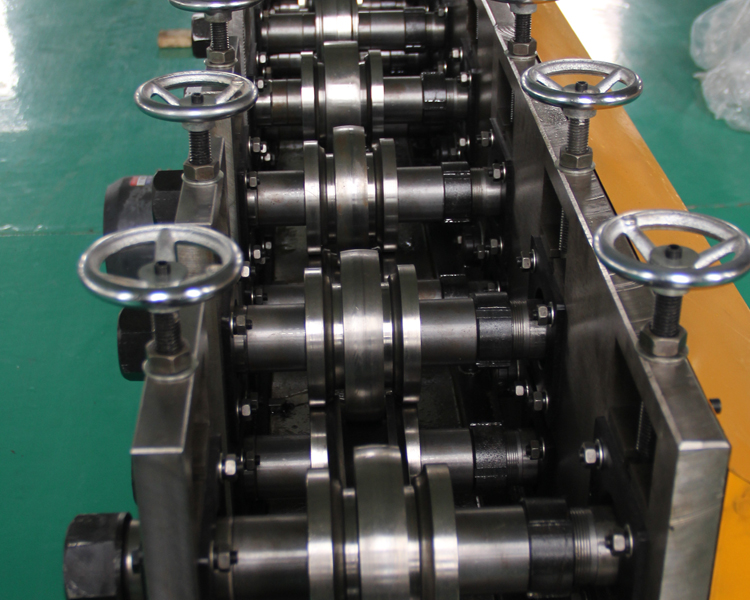

| 10 | Roller Stations | About 20 stations |

| 11 | Roller Material | Gcr15, coated with chrome HRC58-62 degree |

| 12 | Shaft Material and DIA | ¢70mm, material is 45# forge steel |

| 13 | Maim Motor Power | 11kw brake motor |

| 14 | Hydraulic Station Power | 5.5kw |

| 15 | Hydraulic Pressure | 20Mpa |

| 16 | Capacity of tonnage for punching | 22Tons |

| 17 | Hydraulic pump brand | Lichao |

| 18 | Cutting | Hydraulic post-cutting for cut end product |

| 19 | Extra cutter | One more cutter for each profile |

| 20 | Material Of Cutting | Cr12Mov quenching 58-62ºC |

| 21 | Electric Source | 380V, 60HZ,3 phase |

| 22 | Way Of Drive | 1.2 inch single chain |

| 23 | Color Of The Machine | Yellow and blue |

| 24 | Machine Type | Iron Cast |

| 25 | Emergency switch | In main machine and control panel all have emergency switch for forbid any urgently accident. |

| 26 | Protect cover | Complete mobile safety cover from roll forming to the cutter. |

| 27 | Size of the machine | L*W*H 12m*1.2m*1.2m |

| 28 | Container Need | 1 x40 feet (base on final) |

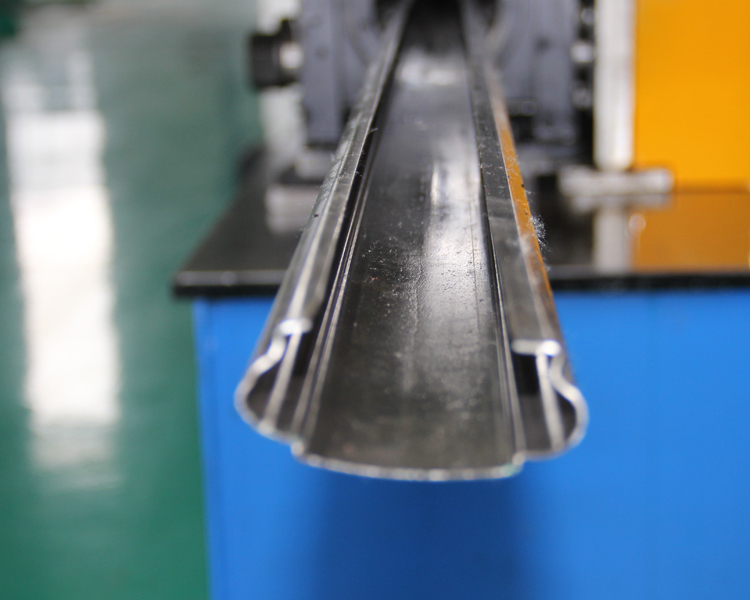

The steel door frame roll forming machine is a complete product line. After roll forming by our production line, we could make very smooth and beautiful steel door frame without any scratch on surface.

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Factory best selling Arching Arch Steel Angle S...

-

Factory supplied Hydraulic Metal Arch Galvanize...

-

Hot sale Factory Light Gauge Keel Steel Roll Fo...

-

China OEM China Nigeria Used Corrugated Roll Fo...

-

2019 High quality recycled plastic steel roof p...

-

Professional Factory for Popular Sheet Metal Ro...