2017 New Style Crimping Curving Machine - Latest Perforated Roller Shutter Door Rolling Form Machine – Haixing Industrial Detail:

With a positive and progressive attitude to customer’s curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of Latest Perforated Roller Shutter Door Rolling Form Machine, Our intention is “blazing new floor, Passing Value”, in the upcoming, we sincerely invite you to definitely improve up with us and make a shiny long term together!

With a positive and progressive attitude to customer’s curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of Latest Shutter Door Rolling Form, Perforated Roller Shutter Door Forming Machine, Roll Shutter Door Roll Forming Machine, Our tenet is “integrity first, quality best”. Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

Machine parameters

|

Roller shutter door roll forming machine |

||

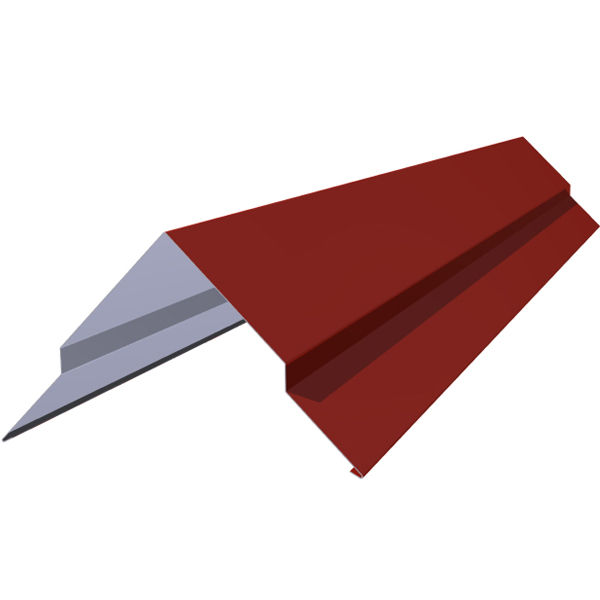

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgs

Manual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

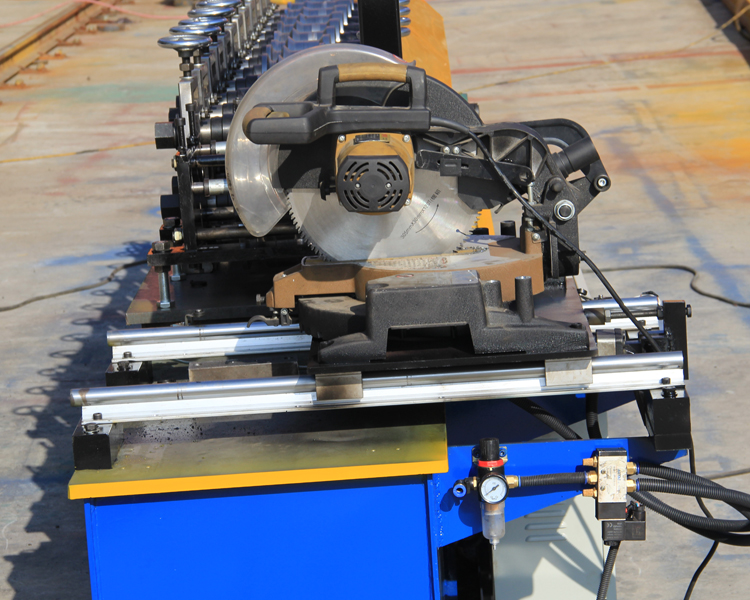

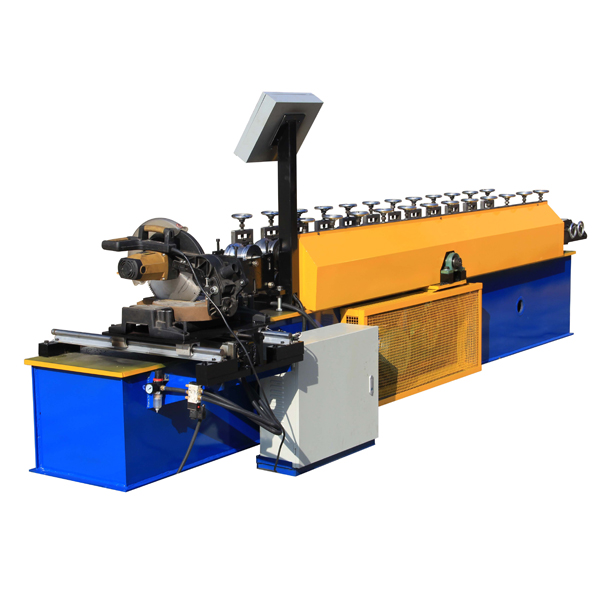

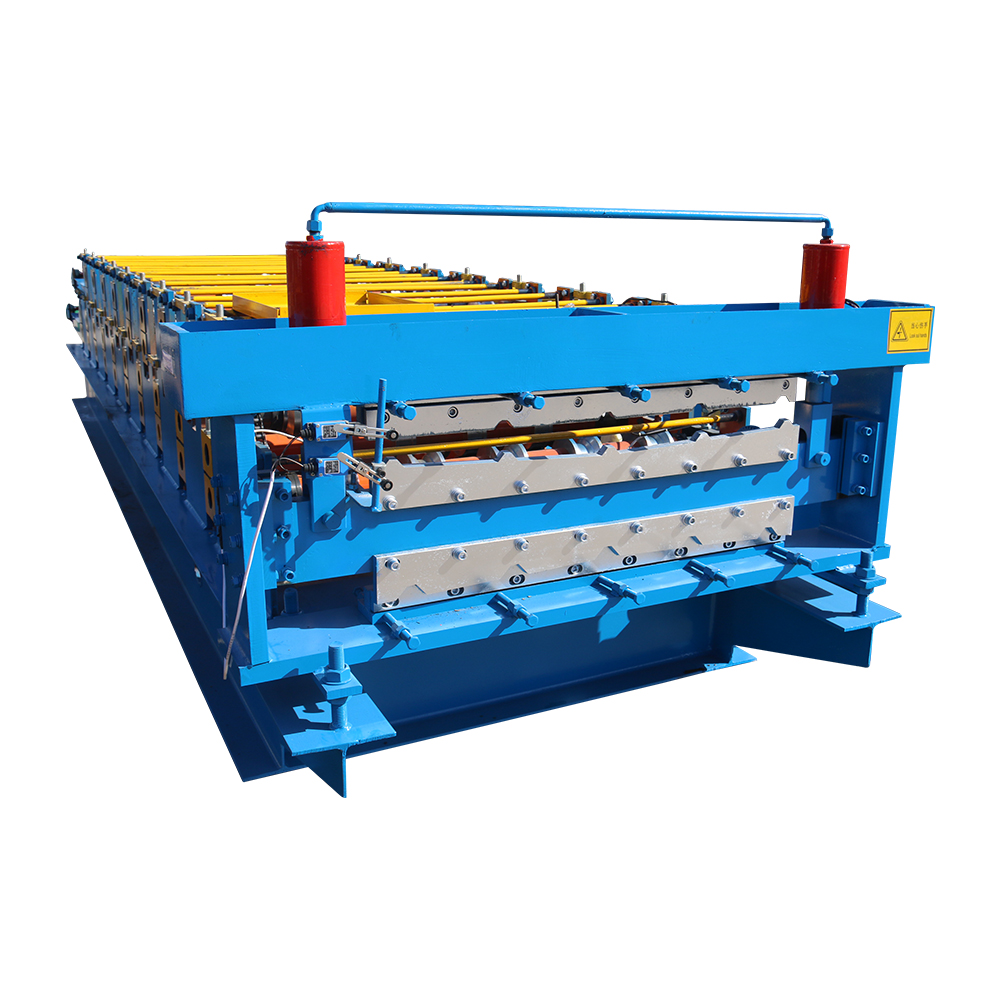

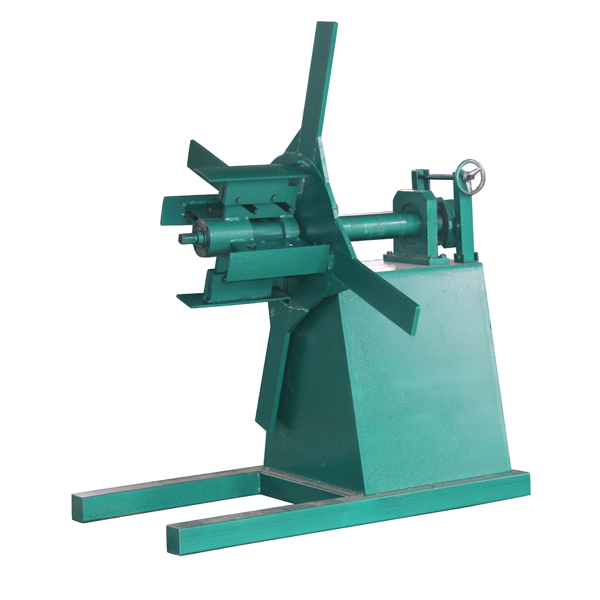

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

Product detail pictures:

Related Product Guide:

A city made of cardboard in an art gallery | Roof Sheet Curving Machine

NFPA-502 Fire Protection Case Histories: Elizabeth River Tunnel and the Hugh L. Carey Tunnel | Roof Sheet Curving Machine

2017 New Style Crimping Curving Machine - Latest Perforated Roller Shutter Door Rolling Form Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

2017 High quality Ceiling T Grid Forming Machin...

-

OEM China Sheet Metal Slitter - Roof Roll Form...

-

Wholesale Price China Wall Panel Curving Roll F...

-

Chinese Professional Z Purlin Rolling Machine -...

-

OEM Customized Manual Bending Machine - Alumin...

-

High definition Water Gutter Metal Machine - 5...