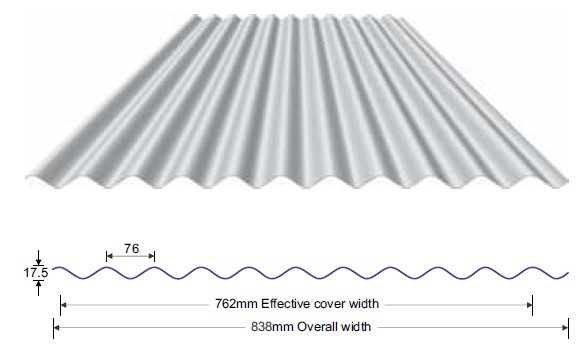

762 Corrugated Roof Metal Sheet Cold Roll Forming Machine parameters:

| 1 | Main motor power | 4kW, 3 phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Main frame | 300/350 mm H-beam |

| 7 | Backboard thickness | 16 mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0-15/ min |

| 12 | Roll station | 13 roll steps (according to different design) |

| 13 | Roller diameter | 70 mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12 |

| 16 | Cr-plating size | 0.05 mm |

Different parts of the machine:

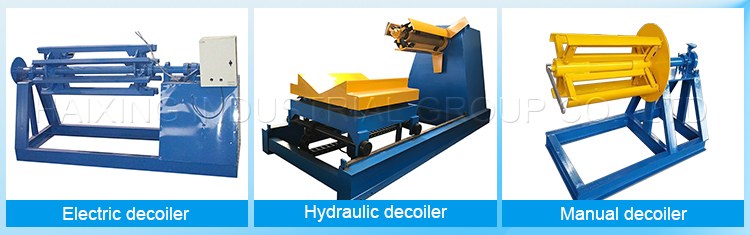

Decoiler: the common machine with 5 tons manual decoiler or you also can choose electric decoiler or hydraulic decoiler

PLC control console:

Roll forming parts and Output table:

Cutting parts: common is hydraulic pump drive cutting or you can choose electric motor drive cutting as follows:

Easy-broken parts: