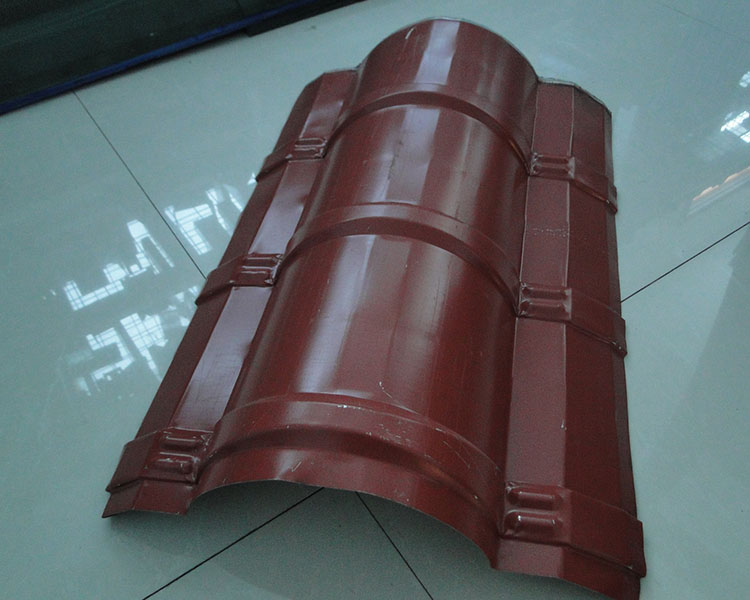

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Cheapest Factory Superior Cold Steel Metal Roof Ridge Cap Roll Forming Machine, Warmly welcome to cooperate and develop with us! we are going to continue to provide product or service with high quality and competitive rate.

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Cold Steel Ridge Cap Roll Forming Machine, Metal Roof Ridge Cap Roofing Machines, Ridge Cap Roll Forming Machine, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

|

metal ridge cap roll forming machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

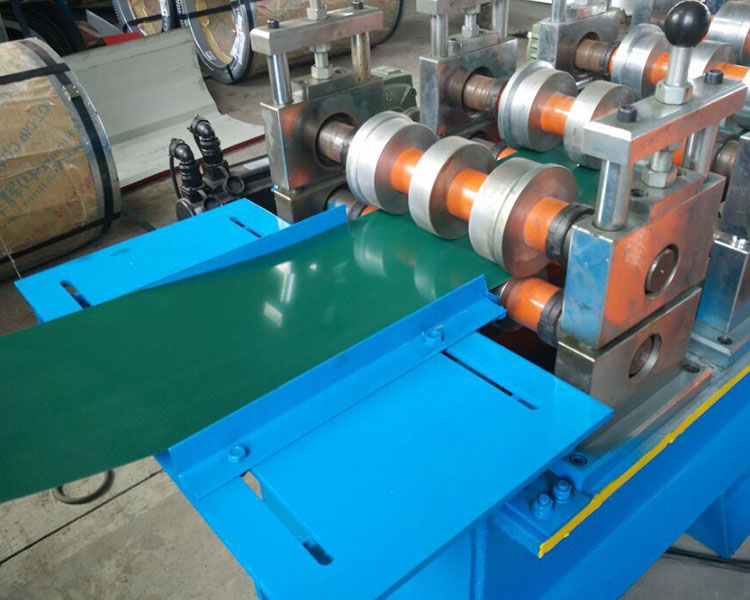

Components of metal ridge cap roll forming machine

1. Manual Decoiler…………………………………………….1 set

2. Feeding Guide……………………………………………….1 set

3. Main Roll Forming Machine……………………………1 set

4. Hydraulic Cutting Device………………………………..1 set

5. Hydraulic Station…………………………………………..1 set

6. PLC Computer Control…………………………………..1 set

7. Output Table…………………………………………………1 set

Machine details:

Package and shipment details:

The machines sold by Haixing Industrial Group Co., Ltd. use standard export packaging, as follows:

1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

-

Leading Manufacturer for Newest Chain Transmiss...

-

Low MOQ for Cold Roof Rolled Formed Galvanized ...

-

Bottom price China Sheet Metal Plate Bending Ma...

-

Wholesale OEM/ODM Steel Automatic Roller Shutte...

-

China Cheap price 2018 Hot Sale Steel Door Fram...

-

OEM Manufacturer Rolling Shutter Door Frame Mac...