We persist with the principle of “quality 1st, assistance initially, continual improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for China Manufacturer for roof ridge tiles building materials machinery metal roof ridge cap roll forming machine, Welcoming fascinated organizations to cooperate with us, we glance ahead to possessing the opportunity of working with companies round the earth for joint development and mutual results.

We persist with the principle of “quality 1st, assistance initially, continual improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for , With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We now have enough confidence to supply you both better merchandise and service, because we have been more and more powerful, specialist and experience in domestic and international.

|

roof ridge making machine parameters |

||

| 1 | Decoiler | Manual decoiler or hydraulic decoiler |

| 2 | Raw material thickness | 0.2-0.8mm |

| 3 | Material | As your requirements |

| 4 | Machine dimensions | 7000*800*1500mm |

| 5 | Feeding width | According to your profile |

| 6 | Forming station | 13 to 15 steps |

| 7 | Shaft diameter | 75mm |

| 8 | Shaft material | High-grade 45# steel, heated and quenched |

| 9 | Roller material | High-grade 45# steel, coated with 0.05mm chrome |

| 10 | Forming speed | 10-15m/minute (adjustable) |

| 11 | Transmission type | Chain transmission |

| 12 | Machine frame stand | Welded structural steel, thickness is 18mm |

| 13 | Main motor | 5.5kW from Shanghai, China |

| 14 | Cutting type | Stop hydraulic cutting |

| 15 | Cutting power | 3kW |

| 16 | Cutter material | Cr12 with quenched treatment HRC 58-62 |

| 17 | Cutting length error | ±2mm |

| 18 | Voltage | 380V/50Hz and 3 or according to your requirements |

| 19 | Control system | PLC control system |

| 20 | Size of PLC | 700*1000*300mm |

| 21 | PLC | Delta/Siemens |

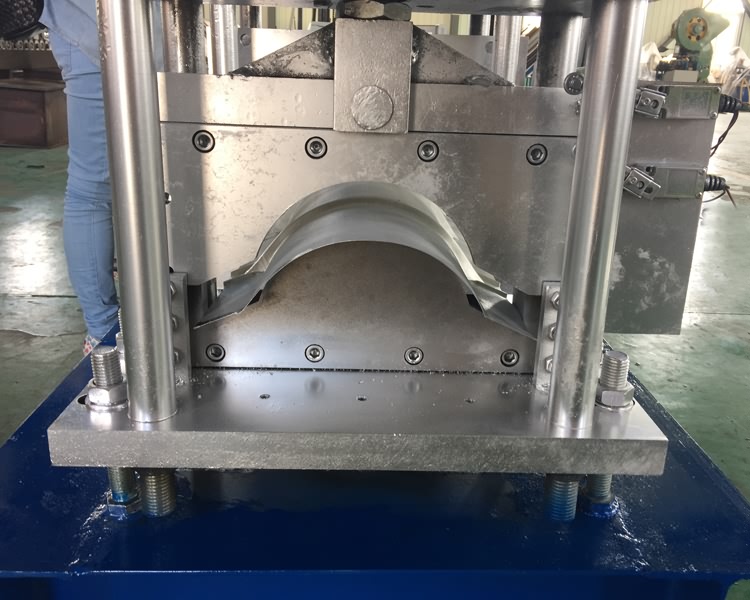

Machine details:

Roof ridge making machine package and shipment details:

Standard export packing: 1 x 40GP container, main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

-

Professional Design China Metal Framing Rolling...

-

Rapid Delivery for Galvanized Steel C U W Chann...

-

Factory made hot-sale Steel Door Frame Metal Ro...

-

Fixed Competitive Price Automatic Wall/roof Pan...

-

OEM/ODM China Hydraulic Steel Coil Decoiler For...

-

Quality Inspection for China Superior Quality M...