We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Chinese Professional Hydraulic Electrical Steel Sheet Shutter Door Guide Rail Cold Roll Forming Machines, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us.

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Automatic Roller Shutter Door Making Machine, Roller Shutter Slates Roll Forming Machine, Shutter Manufacturing Equipment, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

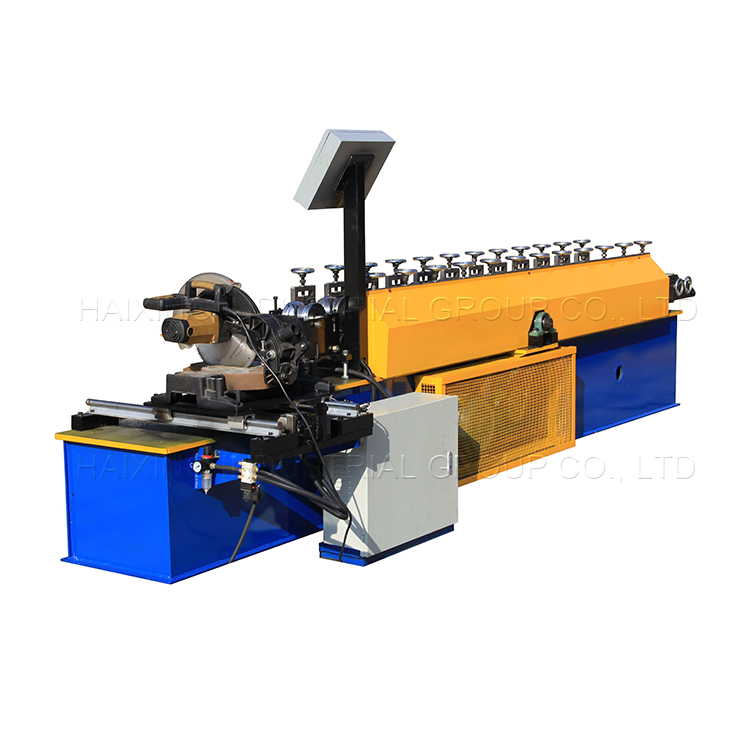

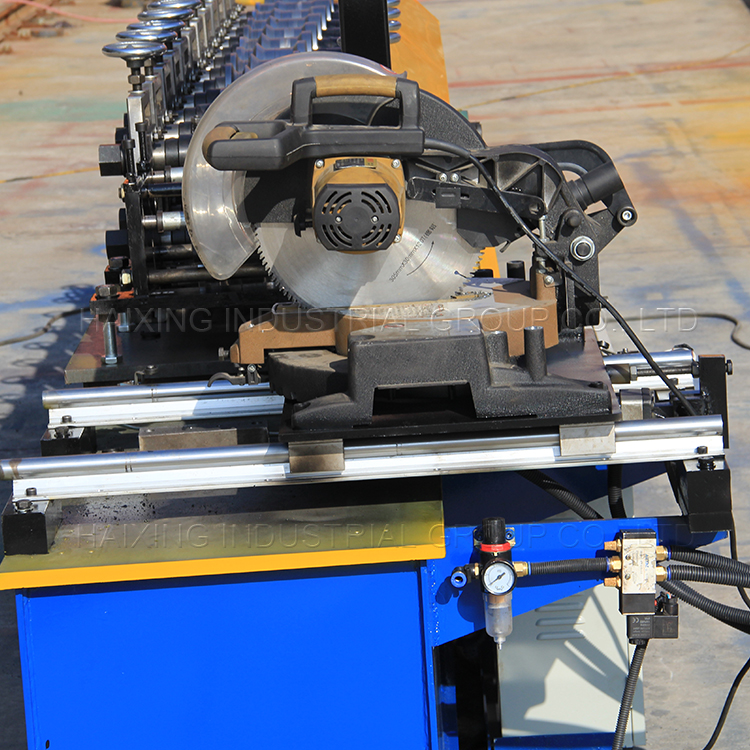

Rolling shutter machine flying saw cutting door forming parameters

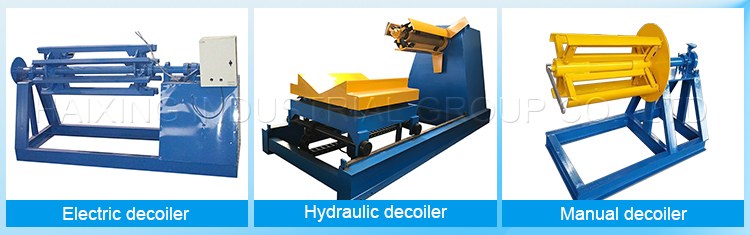

| 1 | Uncoiler | 3tons manual uncoiler |

| 2 | Feeding guide | 2 roller feeding guide |

| 3 | Forming rollers | 14 station rollers |

| 4 | Roller material | 50mm diameter cr12 steel, with twice CNC precise process |

| 5 | Forming body | 100mm x 80mm square pipe with 3.5mm |

| 6 | Forming body outside | With 16mm steel plate welded |

| 7 | Transmission | Gear transmission |

| 8 | Raw material | Galvanized steel, galvalume steel, color steel coil |

| 9 | Raw material thick range | 0.5mm to 1.2mm |

| 10 | Unloading support | 2 pieces 3meter |

| 11 | Main motor | 3KW/4KW |

| 12 | Pump motor | 3KW/4KW |

| 13 | PLC control system | Automatic control system, language: English, Spanish, Russian and so on. |

| 14 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan. Other elements are from famous suppliers of China. |

| 15 | Cutter blades | Cr12 mold steel with quenched treatment. |

| 16 | Factory area | The machine is the 7m length and 2m width, and output sheet according to the customer the longest sheet to calculate |

| 17 | Warrant time | 14 months |

Machine pictures:

Decoilers

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.