We emphasize enhancement and introduce new solutions into the market just about every year for Chinese Professional Low Metal Steel Double Layer Steel Roof Plate Iron Sheet Tiles Cold Roll Forming Making Machine For Roof Panels, We are hunting ahead to building positive and beneficial links with the businesses round the globe. We warmly welcome you to definitely call us to begin discussions on how we can easily bring this into being.

We emphasize enhancement and introduce new solutions into the market just about every year for Colored Corrugated Steel Sheet Roll Forming Machine, Roof Sheet Roll Forming Machine Sales, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, be sure to click the button to acquire additional nformation.

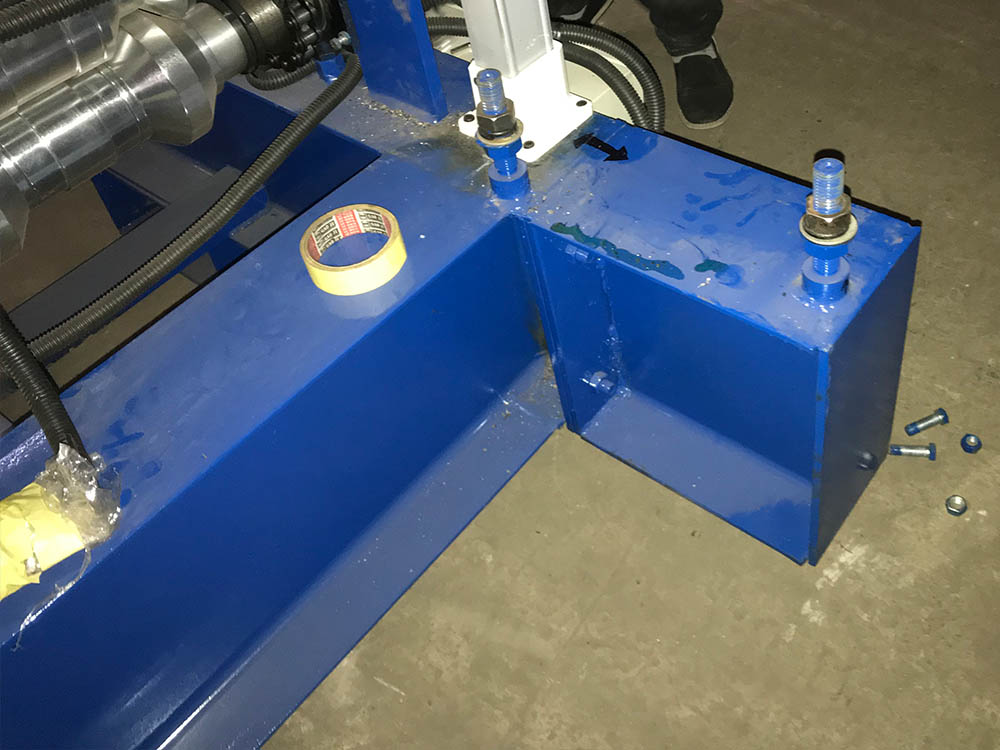

This type of trapezoidal roofing roll forming machine is very popular in Georgia, and its color steel tile has a good quality and beautiful appearance. It is a very worthwhile roll forming machine. The automatic control system of the whole unit of the tile press adopts a highly integrated network to make the performance of the automation system superior.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1200mm |

| 12 | Effective width | 1160mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine details

Machine package and shipment details

Standard export packing: 1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

The advantages of automatic roofing sheet roll forming machine:

1.Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2.Controlling by computer, PLC display, operation is easy, running is steady and reliable,endurable,maintenance-free.

3.We can make and design will kinds of roll forming machine according to customer’s request.