Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers’ demands for Factory Outlets Making Building Material Wall Panel Metal Roofing Corrugated Tile Roll Forming Machine For Sale, sincerity and strength ,constantly preserve approved superior quanlity ,welcome to our factoty for pay a visit to and instruction and organization.

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers’ demands for Manual Roof Tile Making Machine, Sheet Metal Forming Machine, Wall Panel Machine, They’re durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it’s a really should for yourself of excellent good quality. Guided by the principle of “Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We’re confident that we are likely to possess a vibrant prospect and to be distributed all over the world within the years to come.

The automatic control system of the whole unit of the tile press adopts a highly integrated network to make the performance of the automation system superior.

Parameters of double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

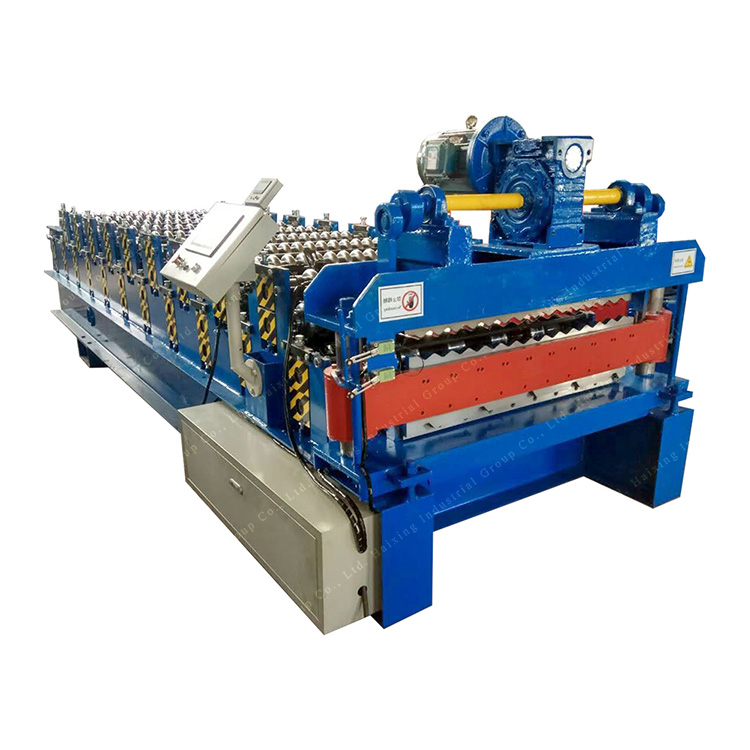

Machine photos

Components of double layer corrugated roof sheet making machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our company owned professional design team, we can design different profile according customer’s demands.

Why choose us ?

Professional:

With 10 years’ professional manufacturing experience in roll forming machinery;

Professional production line,well -trained workers,strict QC standard.

Haixing Industrial Group Co., Ltd. is the biggest and strongest in north China. Our factory is specialized in manufacturing color steel forming machinery, C&Z purlin machine, glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine and other cold roll forming machines.

-

Hot sale Factory Roller Shutter Door Forming Ma...

-

China New Product Corrugated Asos Cement Sheet ...

-

Chinese Professional China Zinc Corrugated Roof...

-

Wholesale ODM Galvanized Steel Standing Seam Ro...

-

Best-Selling Automatic Steel Slitting Line Roll...

-

Reliable Supplier European Standard Of Stainles...