Good Quality Gutter Water Channel Roll Forming Machine - Professional China Used Color Sheet Metal Roof Bending Machine/roof Sheet Crimping Curving Machine – Haixing Industrial Detail:

Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for Professional China Used Color Sheet Metal Roof Bending Machine/roof Sheet Crimping Curving Machine, Influenced from the swift building marketplace of the quick food and beverage consumables all over the planet , We’re wanting forward to operating with partners/clients for making good results together.

Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for Metal Roof Bending Machine, Roof Sheet Crimping Machine, Roof Sheet Curving Machine, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we’re trying our best to be your good partner.

|

Galvanized Curving Roof Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

The advantages of galvanized curving roof machine:

1. Our machines can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

2. Controlling by computer, PLC display, operation is easy, running is steady and reliable, endurable, maintenance-free.

3. We can make and designs will kinds of roll forming machine according to customer’s request.

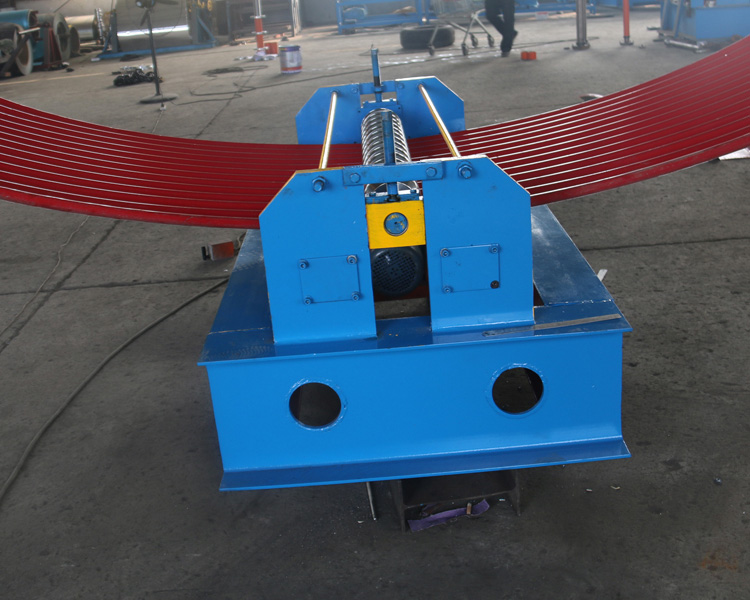

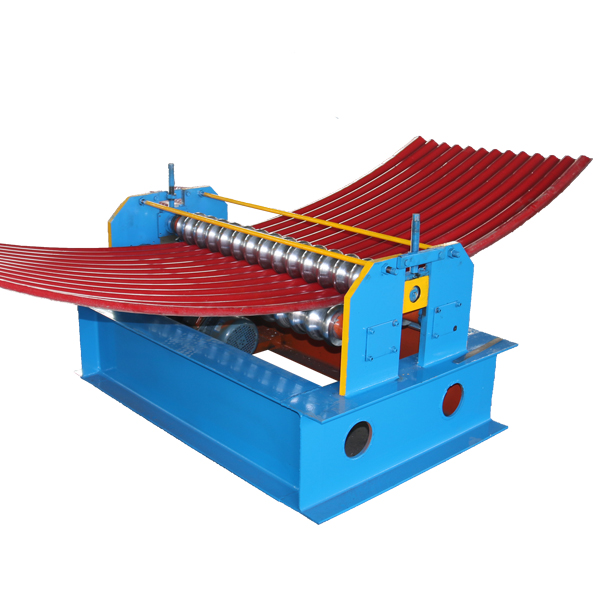

Machine photos:

Product detail pictures:

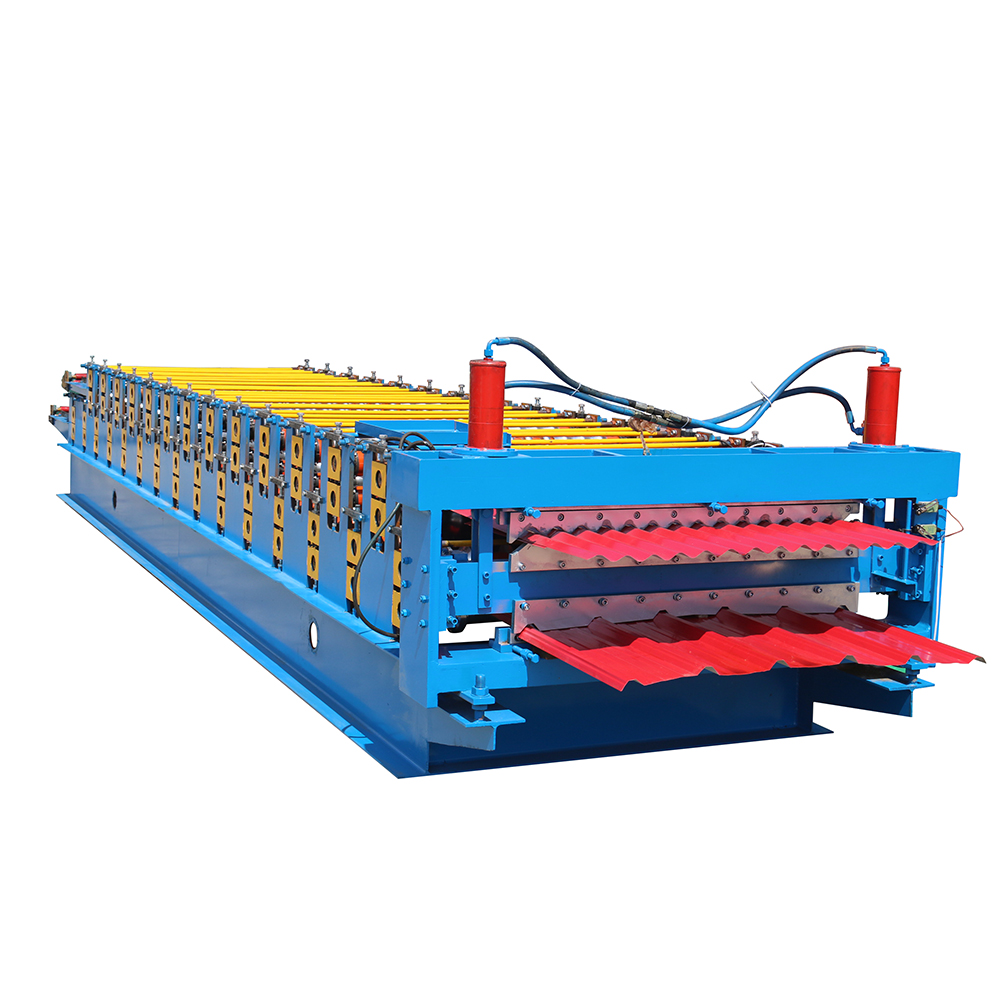

Related Product Guide:

Symphony of the Seas: Giant Royal Caribbean cruise ship arrives in USA | Steel Downpipe Roll Forming Machine

Fallout 76 Bobbleheads Locations Guide | Decoiler In Color Coating Line

Good Quality Gutter Water Channel Roll Forming Machine - Professional China Used Color Sheet Metal Roof Bending Machine/roof Sheet Crimping Curving Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

OEM Factory for Decoiler And Recoiler - Prepai...

-

2017 New Style Slitting Machine For Stainless S...

-

OEM/ODM Manufacturer Tee Wall Angle Ceiling Mak...

-

Excellent quality Water Gutter Making Machine -...

-

China Gold Supplier for Glazed Roof Tile Machin...

-

Hot Sale for Trapezoidal Sheet Roll Forming Mac...