With our excellent management, powerful technical capability and strict high-quality regulate technique, we continue on to provide our consumers with dependable excellent, reasonable rates and outstanding services. We goal at becoming certainly one of your most trustworthy partners and earning your satisfaction for High Performance China Top Quality Aluminum Zinc Painted Steel Metal Roof Panel Double Layer Board Roll Forming Machine, For more information, please contact us as soon as possible!

With our excellent management, powerful technical capability and strict high-quality regulate technique, we continue on to provide our consumers with dependable excellent, reasonable rates and outstanding services. We goal at becoming certainly one of your most trustworthy partners and earning your satisfaction for China Metal Sheet Roll Forming Machine, Roofing Roll Forming Machine, Our technical expertise, customer-friendly service, and specialized goods make us/company name the first choice of customers and vendors. We have been looking for your inquiry. Let’s set up the cooperation right now!

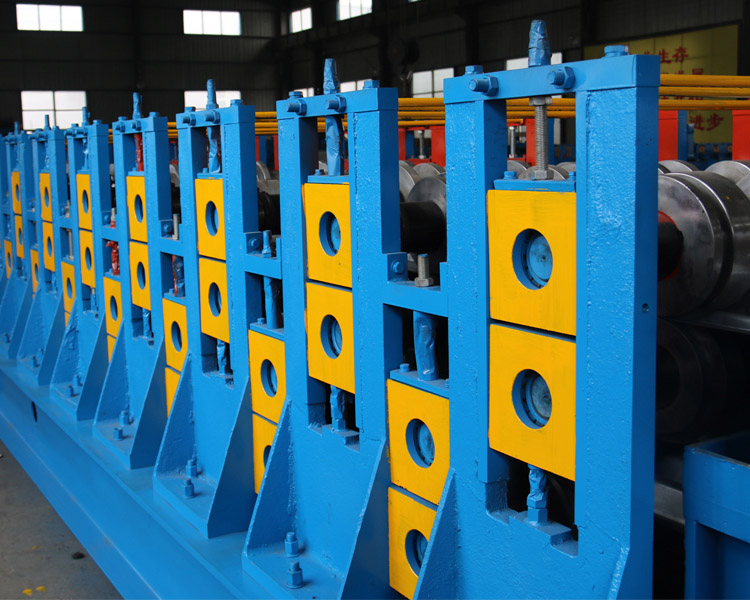

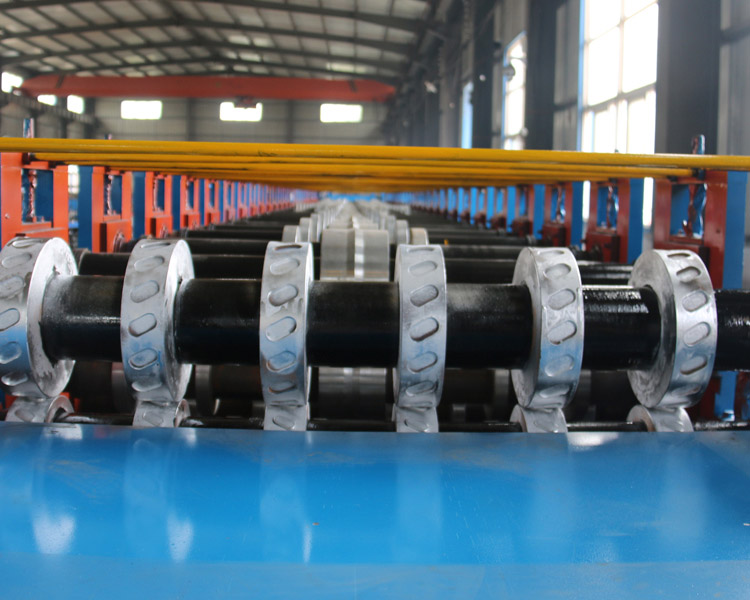

Parameters of steel double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

-

Top Grade China Full Automatic Adjustable Steel...

-

Factory Promotional Automatic Corrugated Pipe F...

-

Factory wholesale Hydraulic Sheet Metal Decoile...

-

Reasonable price Cnc Cutting Machine,Portable C...

-

Factory wholesale Auto Decoiler Uncoiler Decoiler

-

High Quality for Slitting Line Cold Rolled Coil...