We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for High Quality for Double Layer Roof Panel Roll Forming Machine, The team of our company along with the use of cutting-edge technologies delivers impeccable top quality products supremely adored and appreciated by our shoppers worldwide.

We’ve got our personal profits workforce, design and style team, technical group, QC crew and package workforce. We have now strict good quality handle procedures for each process. Also, all of our workers are experienced in printing subject for Double Layer Roll Forming Machine, Roll Forming Machine, Roof Panel Roll Forming Machine, All of our products and solutions comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our products or would like to discuss a custom order, remember to feel free to contact us. We have been looking forward to forming successful business relationships with new clients in the near future.

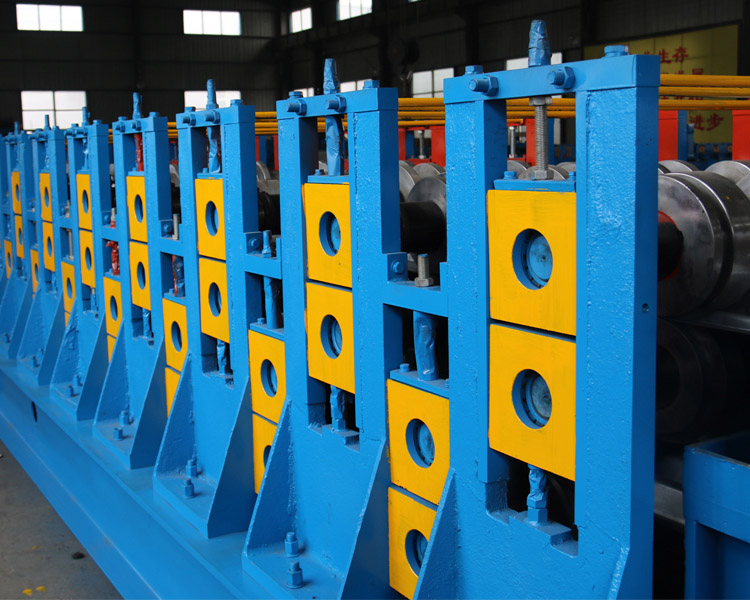

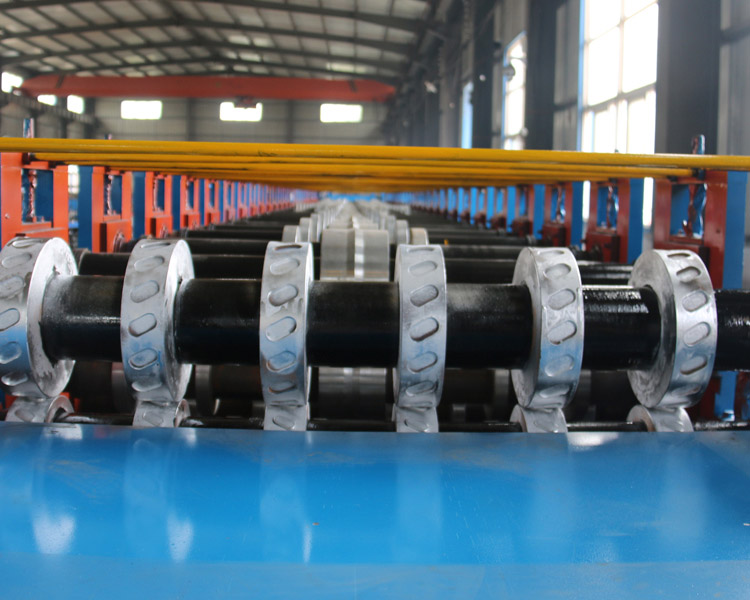

Parameters of steel double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

-

Professional China Galvanized Metal Sheet Squar...

-

New Delivery for Galvanized C Frame Sheet Metal...

-

China New Product Corrugated Asos Cement Sheet ...

-

Chinese Professional China Automatic Adjusted C...

-

New Arrival China Automatic Perforated Steel Sh...

-

Low MOQ for Cold Roof Rolled Formed Galvanized ...