We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for High reputation C Shape Profile Section Light Steel Keel Machine Hf, Our goal should be to create Win-win situation with our prospects. We imagine we will be your finest choice. “Reputation 1st, Customers Foremost. “Waiting for your inquiry.

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for Light C Keel Machine, Light Steel Keel Machine, Steel C Channel Machine, We’ve got won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

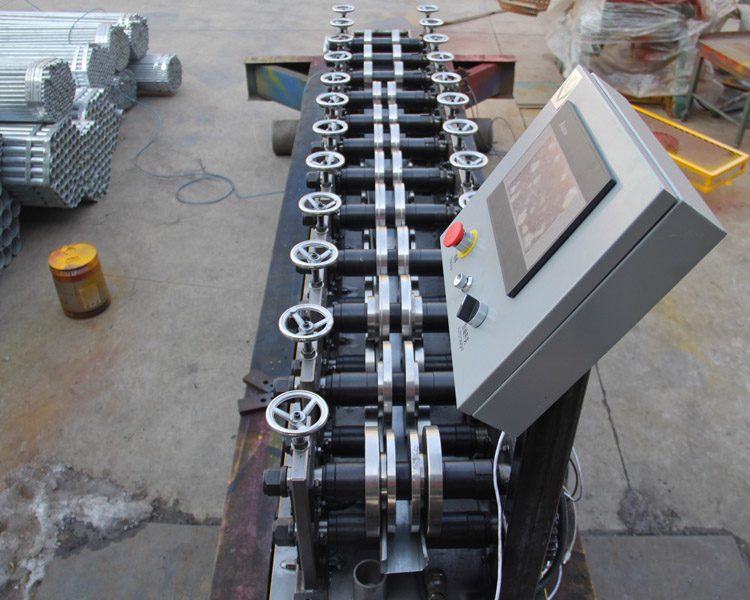

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Wholesale Dealers of Automatic Steel Sheet Deco...

-

Factory directly Russia Popular Safety Door Fra...

-

Rapid Delivery for Widely Used Color Steel Meta...

-

New Fashion Design for Eps Granules Chinses Eps...

-

Hot Sale for Galvanized Aluminum Roof Tile Ridg...

-

Factory Price Trade Assurance Stone Coated Roof...