It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for IOS Certificate Double Deck/double Profile/ Double Layer Roofing Sheets Roll Forming Machine, We will make greater efforts to help domestic and international buyers, and create the mutual benefit and win-win partnership between us. we are eagerly waiting for your sincerely cooperation.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for Double Deck Roll Forming Machine, Double Layer Roll Forming Machine, Double Layer Roof Roll Forming Machine With, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we’ve been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

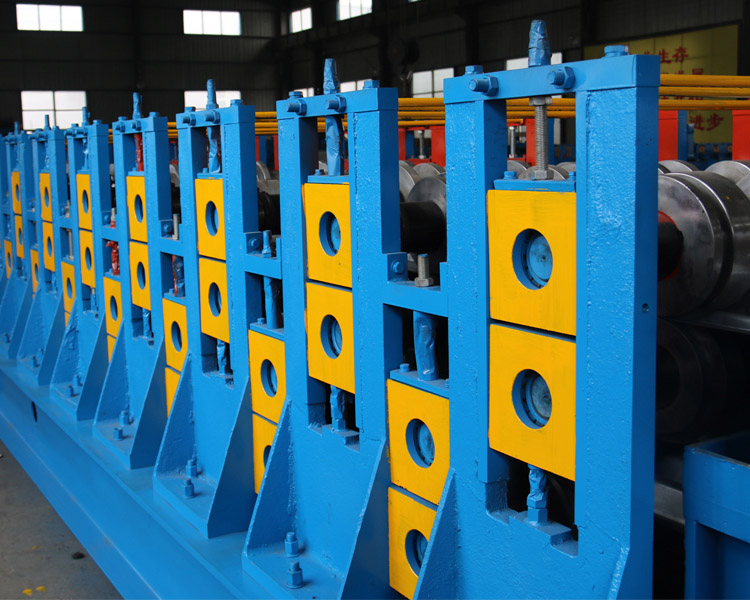

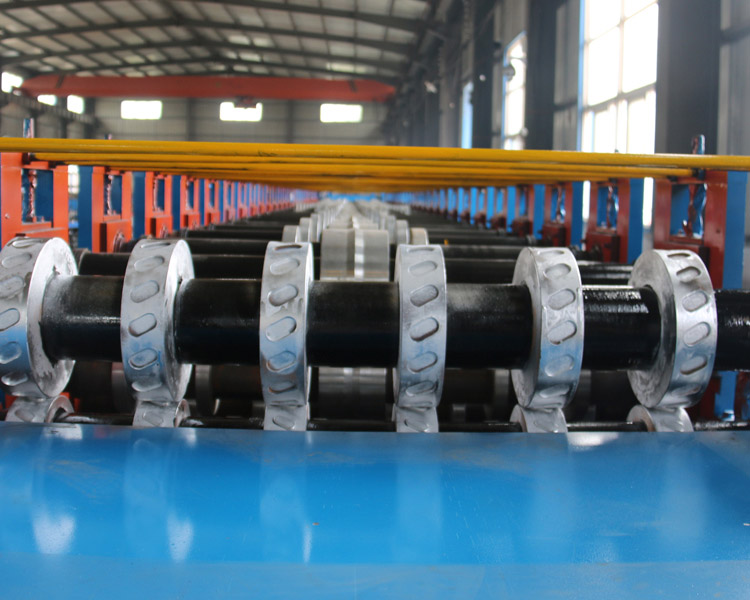

Zinc roofing double layer sheet roll forming machines can press two types of tiles of different versions. Specific version can be customized according to customer requirements.

Parameters of roof tiles making machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

Q:Are you a manufacturer?

A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What’s the delivery time?

Abnormally will take 60 days, for small lines will take 30 days.

Q:Do you have after-sale support?

A:Yes, we’re always here for giving you advice and support for technical details since we have senior technician.

Packing and transport details

|

Packaging details |

Standard export packaging: 1 * 40 GP containers. |

| Main roll forming machine package by Plastic film | |

| Main machine spare parts package by paper box | |

| The electronic equipment is packaged in wooden cases. | |

|

Port |

TIANJIN PORT |

|

Delivery time |

1 – 5 set(s), 25 days |

| >5 sets, To be negotiated |

We have a professional loading technician to ensure that the goods are loaded into the container without any damage.

-

factory low price Roof System-t Shape Corrugate...

-

Reasonable price for Light Steel Keel Cd Ud Pro...

-

factory low price Automatic Galvanized Cold Ste...

-

Supply OEM China CNC Automatic Hydraulic Press ...

-

High Quality Automatic Metal Strips Channel Ben...

-

Big discounting China CNC 4 Side Door Frame Edg...