Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Low MOQ for Corrugated Roofing Sheet Tile Cold Roll Forming Machine Making For Sale, We generally offer most effective top quality merchandise and great assistance for the majority of enterprise users and traders . Warmly welcome to affix us, let’s innovate together, and fly dreams.

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for Cold Roll Forming Machine, Corrugated Roofing Roll Forming Machine, Sheet Tile Roll Forming Machine, With the development and enlargement of mass clients abroad, now we’ve got set up cooperative relationships with many major brands. We have now our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

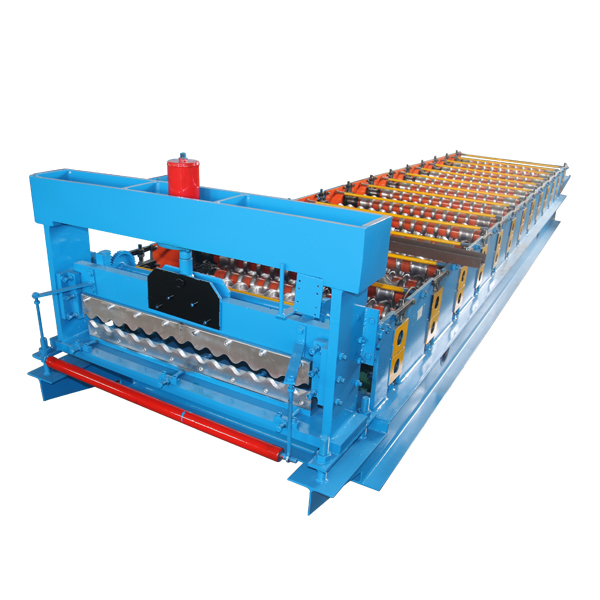

Parameters of corrugated metal roofing sheet machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Photos:

If you have any questions about the model, parameters, etc., please feel free to contact us. We will do our best to answer your questions and look forward to cooperation.

-

Supply ODM Style Low Roller Shutter Door Frame ...

-

OEM Customized C Purlin Roll Forming Machine,C ...

-

Price Sheet for Bonded Stripper Rings For Slitt...

-

Factory Cheap Hot Ibr And Curving Roof Panel Ro...

-

OEM Factory for China Corrugated Roofing Sheet ...

-

Reliable Supplier Corrugated Roofing Sheet Prof...