|

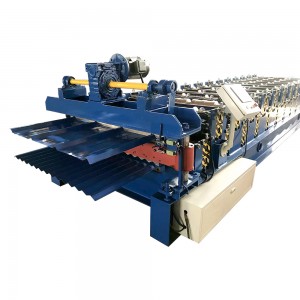

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Feeding width | 1000mm;1000mm |

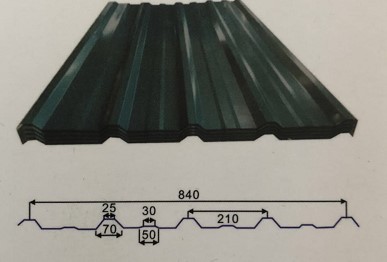

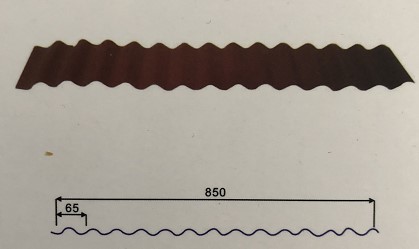

| 12 | Effective width | 840mm;850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 11 roll steps;9 roll steps |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6000*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Package and shipment details:

Standard export packing: 1*20 GP container;

Main machine naked and fastened with iron wire in the container;

Rollers were painted with oil and packed with plastic film;

Electrics devices be packed with wooden box.

Terms:

1. Delivery: within 30 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

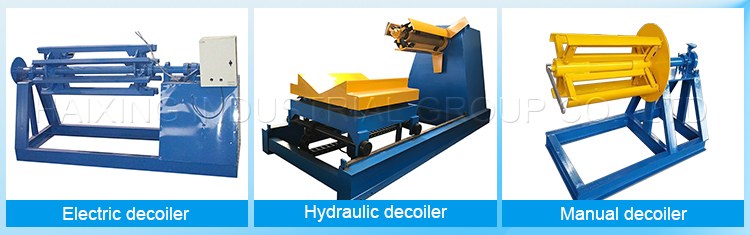

Main parts:

Package:

Drawing:

Detail: