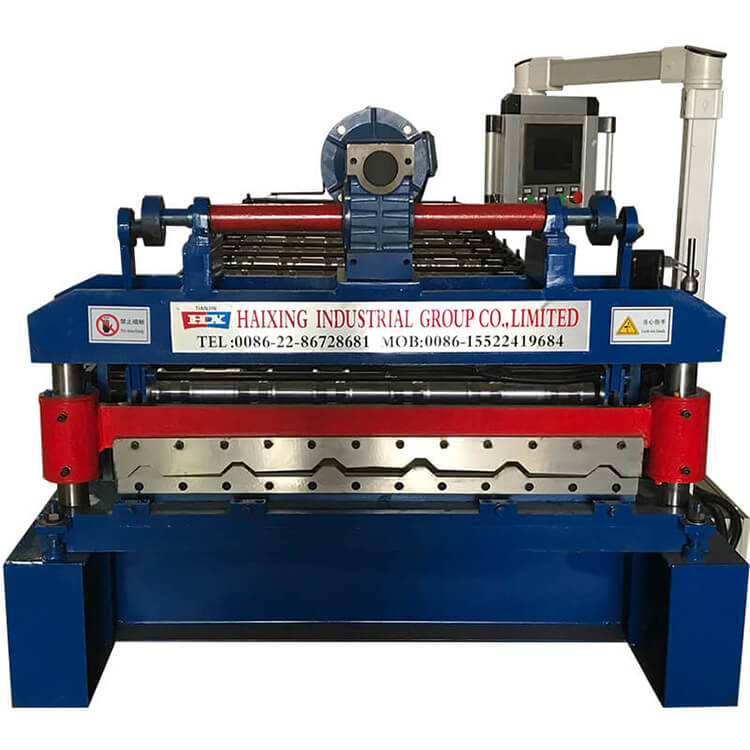

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for Newly Arrival Aluminum Roofing Sheet Roll Forming Machinery single Layer Metal Tile Making Machine In, Presently, we’re seeking ahead to even better cooperation with overseas buyers depending on mutual added benefits. You should sense free to get in touch with us for additional facts.

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we’ve acquired rich practical working experience in producing and managing for Roll Forming Machinery, Steel Roofing Machine, Tile Making Machine, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have the already penetrated. On account of superior quality and competitive price , we will be the market leader, please don’t hesitate to contact us by phone or email, if you are interested in any of our products.

roof tile making machine parameters

| 1 | Main motor power | 4kW/5.5KW/7.5KW or as actual demands |

| 2 | Hydraulic motor power | 3kW/4KW.5.5KW or as actual demands |

| 3 | Hydraulic pressure | 10-12MPa according to oil pump and pump motor |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | Automatic PLC control system |

| 6 | Mainframe | 350H beams/400H beams according to machine demands |

| 7 | Wall sheet thickness | 16mm/18mm/20mm/22mm according to machine demands |

| 8 | Chain size | 1 inch/1.2inch according to machine demands |

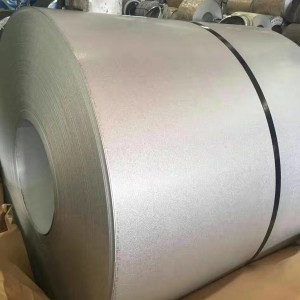

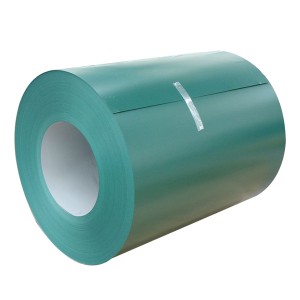

| 9 | Feeding material | Galvanized steel coil/color steel coil/aluminum steel coil |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0 – 25m/min (according to machine specification) |

| 12 | Roll station | Common 11rolls or 25rolls (according to different design) |

| 13 | Roller diameter | 70mm/75mm/80mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12MOV |

| 16 | Cr-plating size | 0.05 mm |

Machine characteristics: Power saving, cheap, labor-saving, fast speed, convenient transportation, and small floor space.

We offer our customers easy-broken parts for free.

Source of raw materials for roof tile making machine

Medium plate: from Baogang steel, Tangshan Iron and Steel, Anshan Iron and Steel, the above-mentioned production areas are all China’s first-class large-scale steel production base.

H-beam: from Tangshan Iron and Steel, Hebei Iron and Steel, specializing in the production of H-beams in China.

The wheels and shafts are made of round steel, which is from Baogang steel, Jigang steel and Tangshan Iron and Steel Co., Ltd., which are produced by a full set of imported Japanese production lines, with high precision components and mechanical properties.

The motor, frequency converter, touch screen, and PLC are all Siemens brands from Germany and are the most professional and best quality manufacturers in the world.

Pumping station: Shanghai Licha, a well-known Chinese brand, guarantees that there will be no quality problems after 10 to 15 years of use.

Blade and hand knife: Cr12 Mov, from Shanghai Baogang steel, Japan’s Xiangpu Steel, hardness up to HR800, high-temperature resistance up to 3000 degrees Celsius.

Tubing, chain and bearing: The company’s procurement team consists of 10 people, and the purchased products have all passed the preliminary verification. The oil pipe is guaranteed not to age or block for 8 to 10 years; the chain is guaranteed not to break for 8 to 10 years; the bearing is guaranteed to have no crack for 8 to 10 years.

1. The main machine is covered with plastic film.

2. PLC control box, spare parts, and other small parts are packed by wooden cartons.

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3)Q: How does your factory do regarding quality control?

A: Quality is the priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers’ specifications, using top brand name components.

5) Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.