Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for OEM Factory for Yx16-729yx23-760 Cnc Glazed Metal Shaping Double Layer Roof Sheet Roll Forming Machine, Fantastic good quality, competitive costs, prompt delivery and dependable provider are guaranteed Kindly let us know your quantity requirement under each size category so that we can easily inform you accordingly.

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for Double Layer Machine, Metal Shaping Machine, Roll Formign Machine, With more and more Chinese merchandise around the world, our international business is developing rapidly and economic indicators big increase year by year. We’ve got enough confidence to offer you both better solutions and service, because we are more and more powerful, qualified and experience in domestic and international.

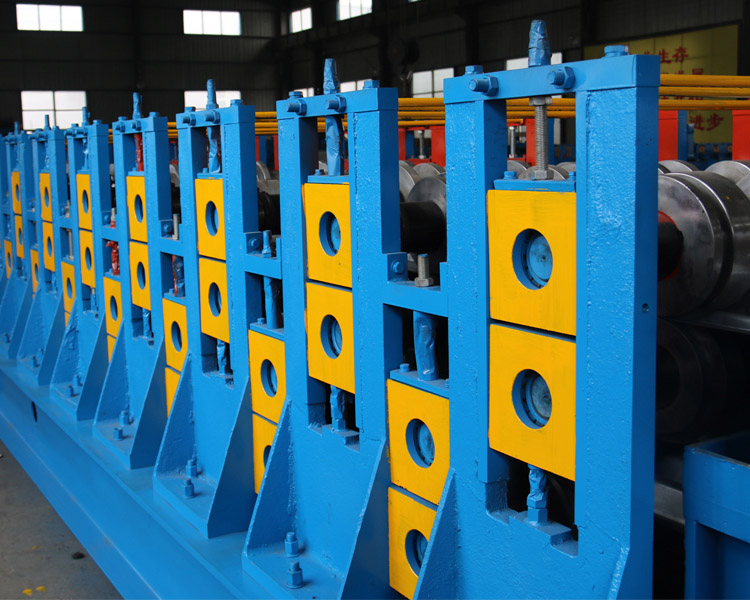

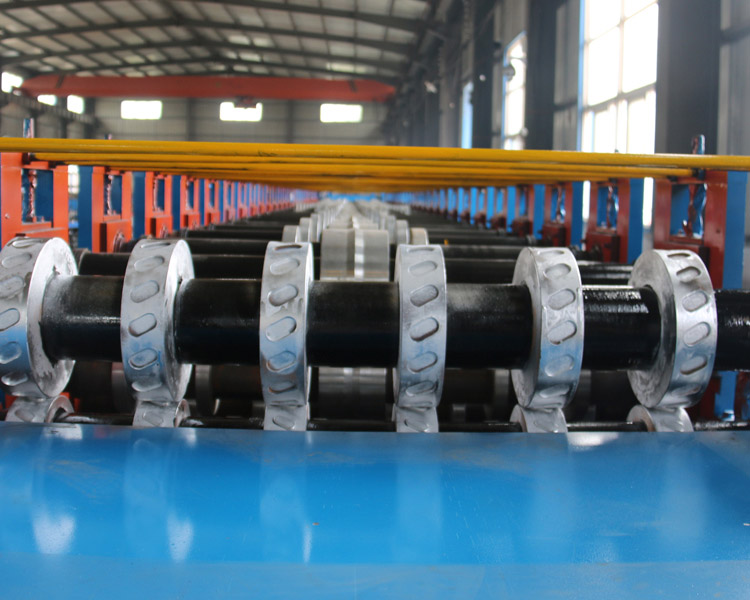

Parameters of steel double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

-

Renewable Design for Metal Roofing Sheet Double...

-

Factory Promotional China 686 Ibr Roof Sheet Ro...

-

OEM Supply Metal Roof Panel Roll Forming Machine

-

Good Quality China Large Visual Contour Cutting...

-

Quots for Fire Resistance Door Panel Roll Formi...

-

Newly Arrival China Multi Function Mattresses C...