Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for OEM Supply Fenestrated Shutter Door Roll Forming Machine Roller Door Roll Former Rolling Shutter Strip Making Machine, Our intention is to assist clients to understand their ambitions. We are earning wonderful attempts to realize this win-win predicament and sincerely welcome you to be a part of us.

Each individual member from our significant effectiveness gross sales workforce values customers’ demands and small business communication for Rolling Shutter Machine, Shutter Door Roll Forming Machine, Shutter Machine, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage. C, Various types: Welcome your inquiry, It will be highly appreciated.

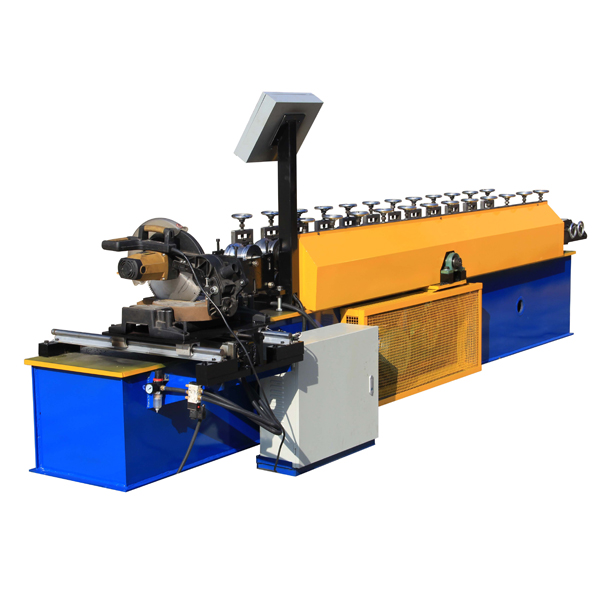

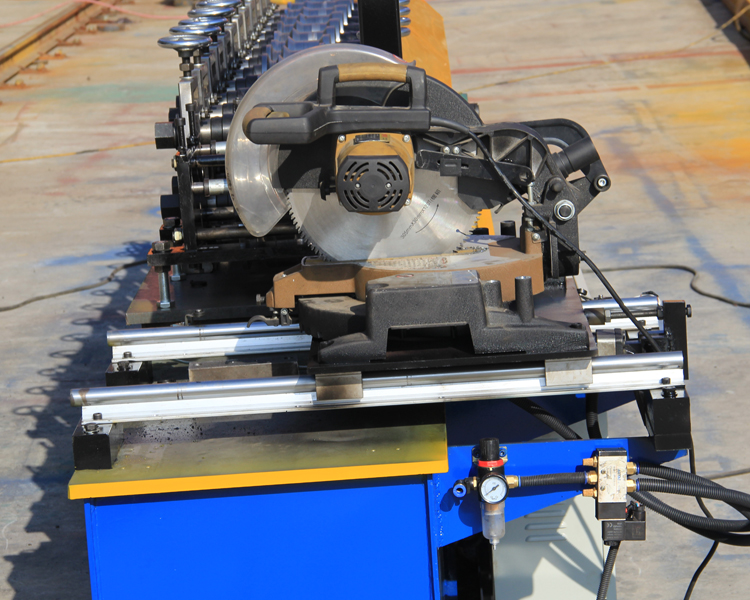

Machine parameters

|

Roller shutter door roll forming machine |

||

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgsManual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

-

10 Ton Hydraulic Decoiler With Coil Car

-

1020 Trapezoidal Roof Sheet

-

960 Glazed Roof Tile Sheet

-

Aluminum T Grid Roll Forming Machine

-

ASA plastic synthetic resin roof tile

-

Aluminum Roofing Sheet Roll Forming Machine Dou...

-

Automatic CZ Shaped Steel Purlin roll Forming M...

-

Automatic CZ interchange purlin machine

-

Automatic Sheet Coil Slitting Machine

-

Automatic Roofing Sheet Roll Forming Machine