OEM/ODM Factory Ibr Sheet Bending Machine - New Fashion Design for Roll Shutter Door Roll Forming Machine In – Haixing Industrial Detail:

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for New Fashion Design for Roll Shutter Door Roll Forming Machine In, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value “unification, dedication, tolerance” for Roller Shutter Door Machine, Rolling Shutter Slats Roll Forming Machine, Used Roller Shutter Roll Forming Machine, We insist on “Quality First, Reputation First and Customer First”. We are committed to providing high-quality products and good after-sales services. Up to now, our products have been exported to more than 60 countries and areas around the world, such as America, Australia and Europe. We enjoy a high reputation at home and abroad. Always persisting in the principle of “Credit, Customer and Quality”, we expect cooperation with people in all walks of life for mutual benefits.

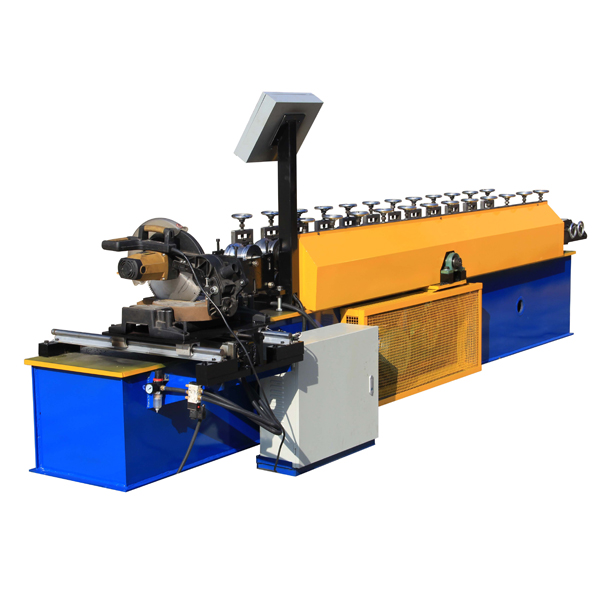

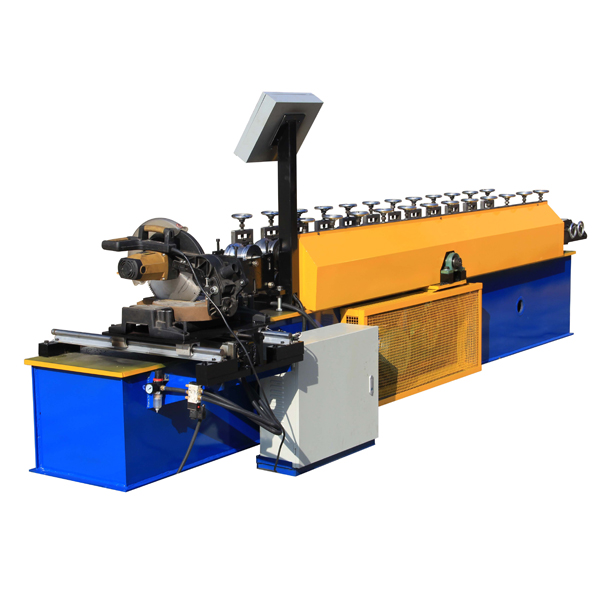

Machine parameters

|

Roller shutter door roll forming machine |

||

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgs

Manual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

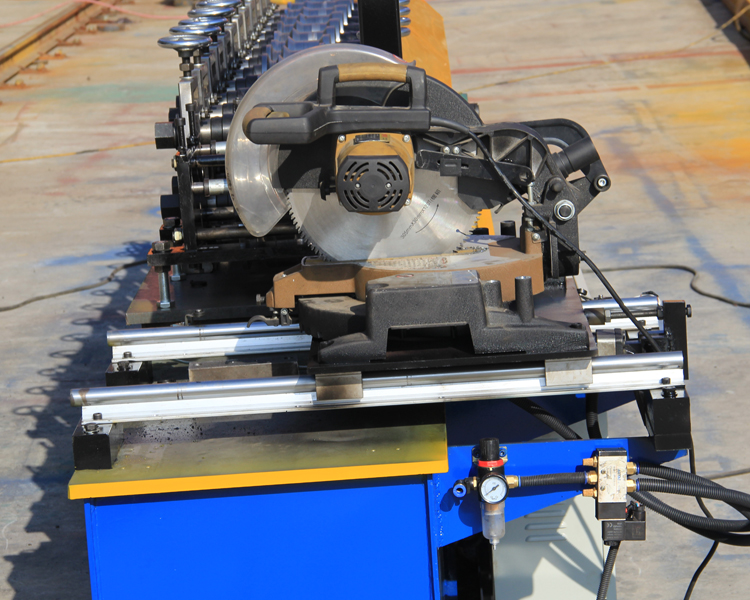

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

Product detail pictures:

Related Product Guide:

Chocolate, bioterrorism and the birth of Brazilian funk Engadget Engadget save share save share save share save share save share ear icon eye icon text file vr | Decoiler In Color Coating Line

Not Just Another Megaship, Norwegian Bliss Showcases The Broad Appeal Of Cruise Vacations | Decoiler In Color Coating Line

OEM/ODM Factory Ibr Sheet Bending Machine - New Fashion Design for Roll Shutter Door Roll Forming Machine In – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Original Factory Gutter Cold Roll Forming Manuf...

-

Renewable Design for Curving Machine - Trendin...

-

Manufacturing Companies for Roll Form Machine R...

-

Renewable Design for Metal Roofing C Stud Makin...

-

8 Year Exporter Metal Sheet Cut To Length Line ...

-

Professional China Ceiling T Bar T Grid Machine...