Our commission is to provide our end users and clientele with best high quality and competitive portable digital merchandise for Original Factory Roof Metal Sheet Roll Forming Machine Construction Equipment And Wall Tiles, We put genuine and health as the primary responsibility. Now we have a professional international trade crew which graduated from America. We’ve been your next enterprise partner.

Our commission is to provide our end users and clientele with best high quality and competitive portable digital merchandise for Roof And Wall Tiles Machine, Roof Construction Equipment, Roof Metal Sheet Roll Forming Machine, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of “credit oriented, customer first, high efficiency and mature services”, we warmly welcome friends from all walks of life to cooperate with us.

The glazed roof tile formed by the glazed roofing tile roll forming making machine has the characteristics of beautiful appearance, simple and elegant, exquisite shape and noble taste.

It can be widely used in villas, resorts, garden-style factories, tourist attractions, pavilions, hotels, exhibition halls and other buildings.

|

Roof roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 836mm |

| 13 | Productivity | 0-15/min |

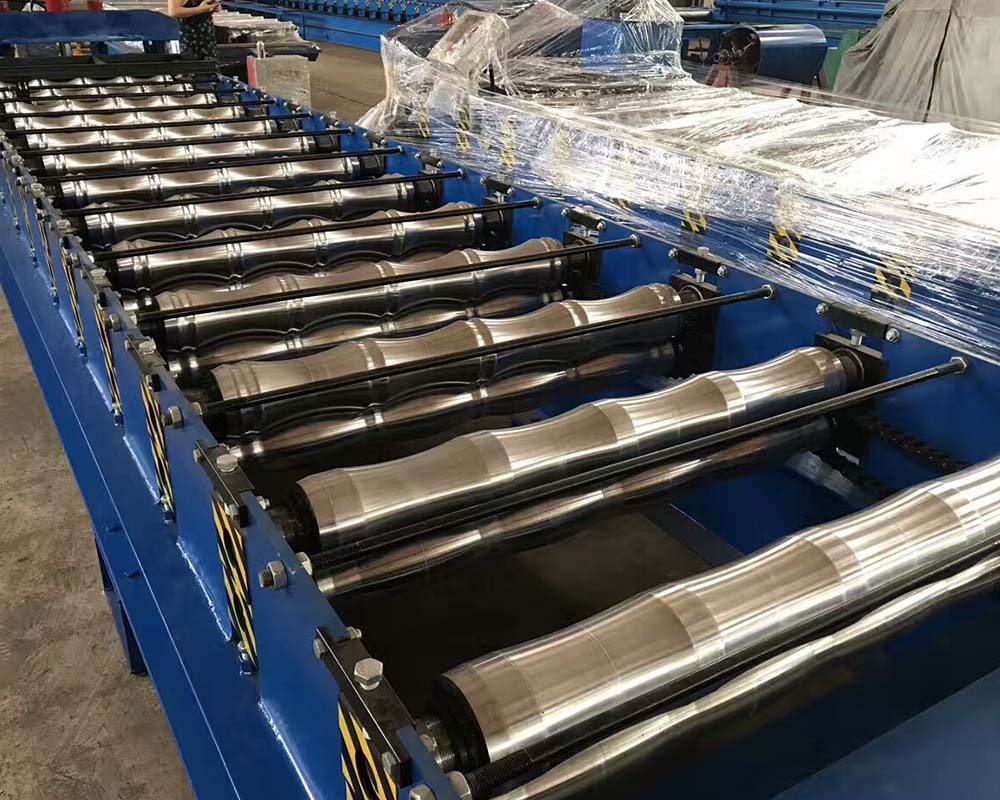

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual decoiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Good Wholesale Vendors C U T L Omega Channel Ro...

-

Good Quality China Large Visual Contour Cutting...

-

Factory source Metal steel slitting machine sli...

-

Top Grade Lms Manual And Hydraulic Decoiler 10 ...

-

Special Price for China Door Frame/Base Board S...

-

Free sample for China Portable Construction Roo...