The key to our success is “Good Product Excellent, Reasonable Rate and Efficient Service” for Reasonable price Glazed Roofing Tile Making Machine, Winning customers’ trust will be the gold key to our accomplishment! Should you be fascinated in our merchandise, you should experience cost-free to go to our web site or contact us.

The key to our success is “Good Product Excellent, Reasonable Rate and Efficient Service” for Metal Sheet Glazed Roofing Tile Making Machine.cold Roll Forming Machine For Sale, Metal Sheet Machine, Metal Shingle Forming Machine, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The automatic control system of the whole unit of the tile press adopts a highly integrated network to make the performance of the automation system superior.

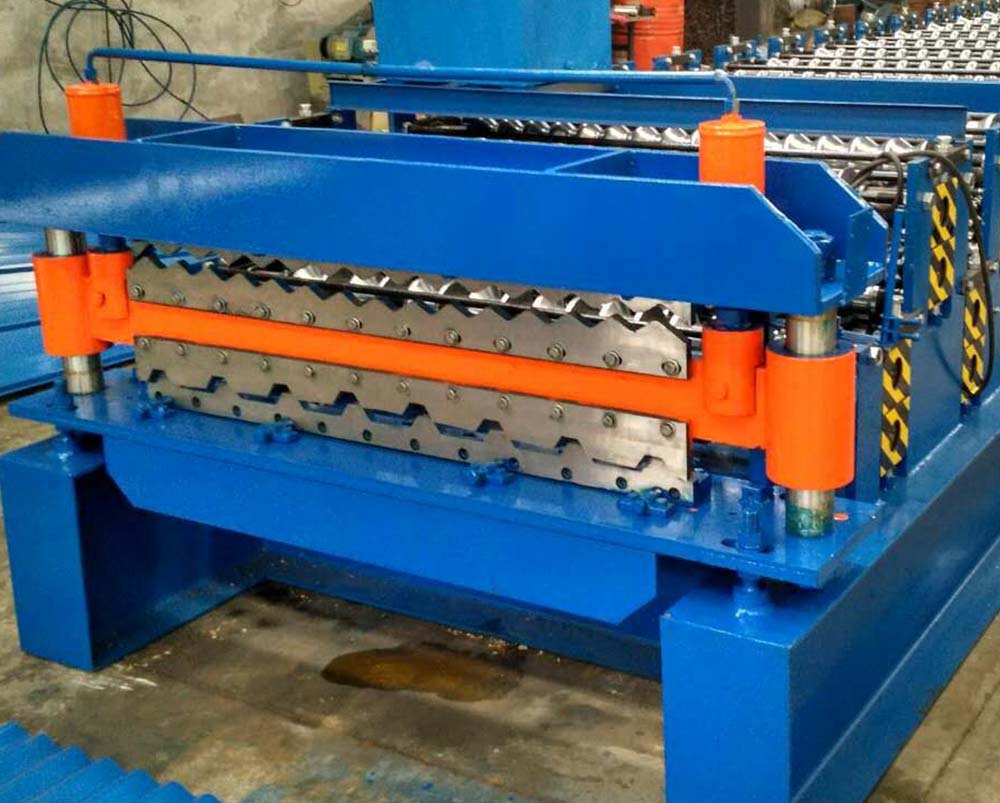

Parameters of double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Components of double layer corrugated roof sheet making machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our company owned professional design team, we can design different profile according customer’s demands.

Why choose us ?

Professional:

With 10 years’ professional manufacturing experience in roll forming machinery;

Professional production line,well -trained workers,strict QC standard.

Haixing Industrial Group Co., Ltd. is the biggest and strongest in north China. Our factory is specialized in manufacturing color steel forming machinery, C&Z purlin machine, glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine and other cold roll forming machines.